Ship piping series washing loop connection method and device, storage medium and terminal

A technology of circuit connection and connection method, applied in the direction of geometric CAD, etc., can solve problems such as heavy workload, design errors, artificial design of ship serial washing circuit, etc., and achieve the effect of improving production efficiency and accuracy and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In order to solve the technical problems existing in the prior art, an embodiment of the present invention provides a method for connecting series washing circuits of ship piping systems.

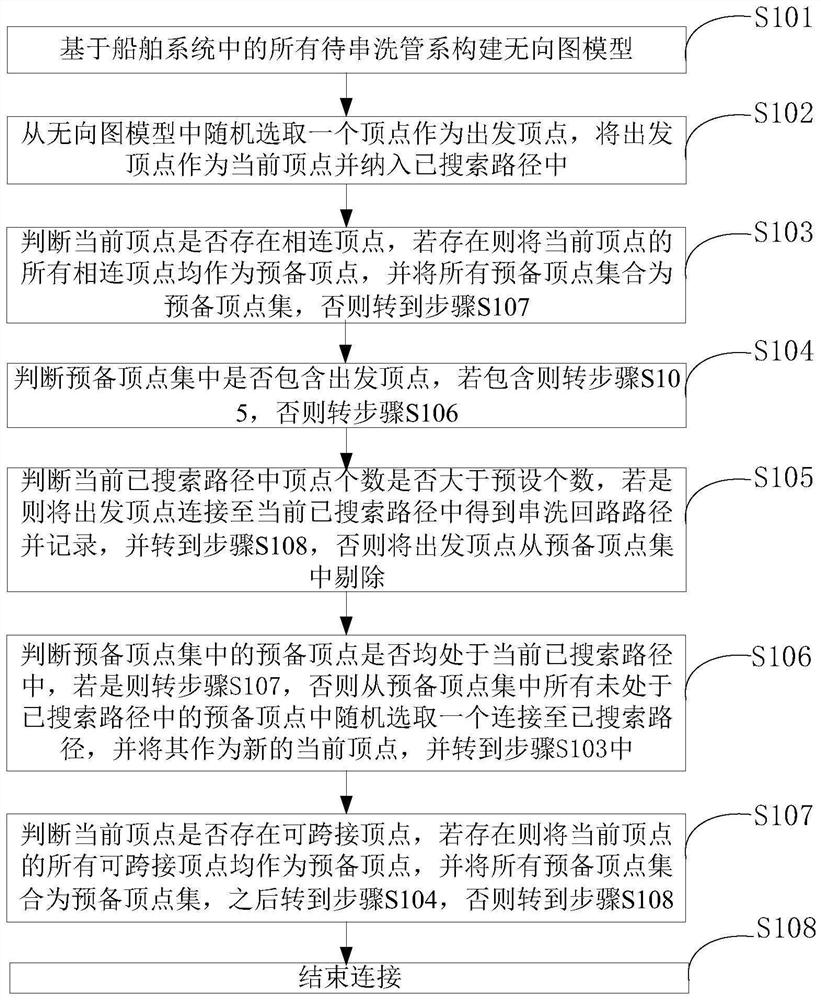

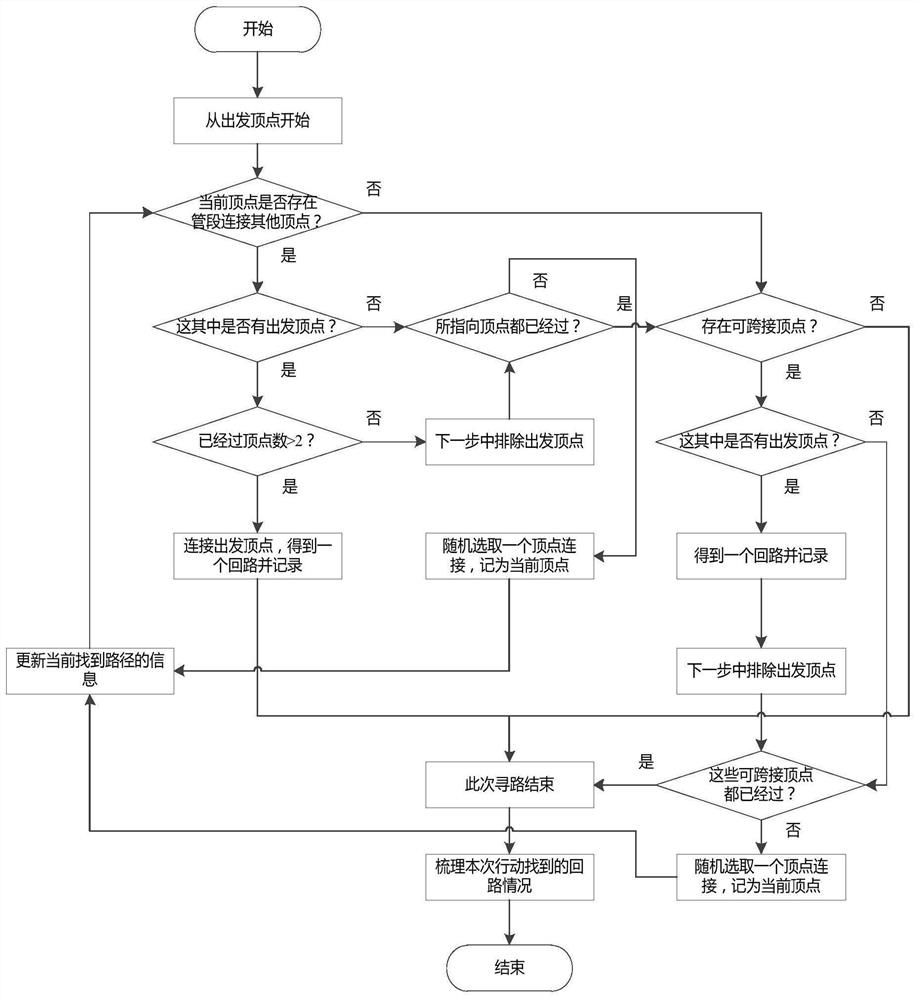

[0050] figure 1 It shows a schematic flow diagram of a method for connecting a series washing circuit of a ship piping system according to an embodiment of the present invention; figure 2 It shows a schematic diagram of the implementation process of the embodiment of the present invention-the connection method of the serial washing circuit of the ship piping system; refer to figure 1 and figure 2 As shown, the method for connecting the serial washing circuit of the ship piping system in the embodiment of the present invention includes the following steps.

[0051] Step S101, constructing an undirected graph model based on all pipe systems to be serially washed in the ship system.

[0052] Specifically, the piping system to be serially washed in the ship system is referred to as th...

Embodiment 2

[0090] In order to solve the technical problems existing in the prior art, an embodiment of the present invention provides a connection device for series washing circuits of marine piping systems.

[0091] Figure 4 It shows the schematic flow diagram of the second embodiment of the present invention for the connection device of the series washing circuit of the ship piping system; refer to Figure 4 As shown, the connection device of the series washing circuit of the ship piping system in the embodiment of the present invention includes an undirected graph generation module, a departure vertex setting module, an adjacent vertex judgment module, a departure vertex judgment module, a searched path vertex number judgment module, a searched path Judgment module, bridgeable vertices judgment module and algorithm end module.

[0092] The undirected graph generation module is used to construct an undirected graph model based on all piping systems to be washed in series in the ship ...

Embodiment 3

[0102] In order to solve the above-mentioned technical problems existing in the prior art, the embodiment of the present invention also provides a storage medium, which stores a computer program, and when the computer program is executed by a processor, it can realize the serial washing circuit of the ship piping system in the first embodiment All steps in the connection method.

[0103] The specific steps of the method for connecting the serial washing circuit of the ship piping system and the beneficial effects obtained by applying the readable storage medium provided by the embodiment of the present invention are the same as those of the first embodiment, and will not be repeated here.

[0104] It should be noted that the storage medium includes various media capable of storing program codes such as ROM, RAM, magnetic disk or optical disk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com