Method for improving long cycle performance of thick electrode of layered positive electrode material under high voltage

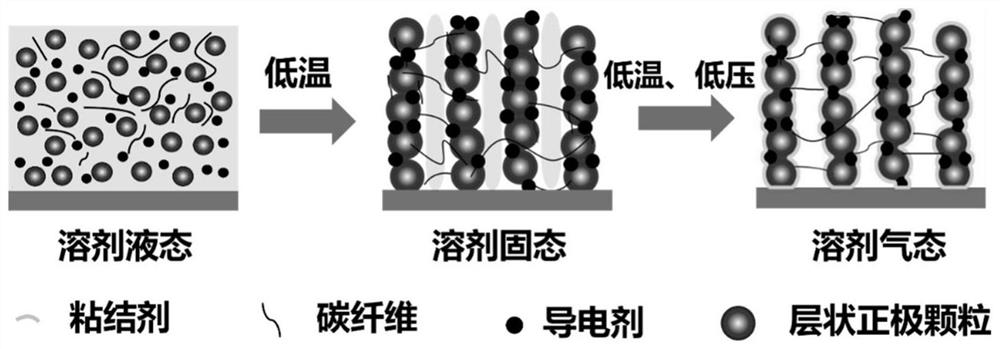

A positive electrode material and high-voltage technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor high-voltage performance of thick electrodes, and achieve the effects of accelerating lithium ion transmission, improving power performance, and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention is used for the preparation of a thick electrode of a layered positive electrode material, and the electrode active material in step (1) is selected from lithium cobaltate or a ternary positive electrode material, and the ternary positive electrode material is LiNi x co y mn 1-x-y o 2 , where 0≤x≤1, 0≤y≤1. For example, the ternary cathode material LiNi 5 co 3 mn 2 o 2 ,LiNi 6 co 2 mn 2 o 2 ,LiNi 7 co 1 mn 2 o 2 , LiNi 8 co 1 mn 1 o 2 Wait. The increase of nickel content in layered cathode materials is accompanied by the increase of specific capacity.

[0036] In some embodiments, the water-based binder in step (1) is selected from one of sodium alginate, guar gum, polyacrylic acid, polyacrylonitrile, polyacrylate, styrene-butadiene rubber emulsion and carboxymethyl cellulose Or a mixture of several types. In a preferred embodiment, the binding agent is a mixture of guar gum, carboxymethyl cellulose or polyacrylic acid, and these...

Embodiment 1

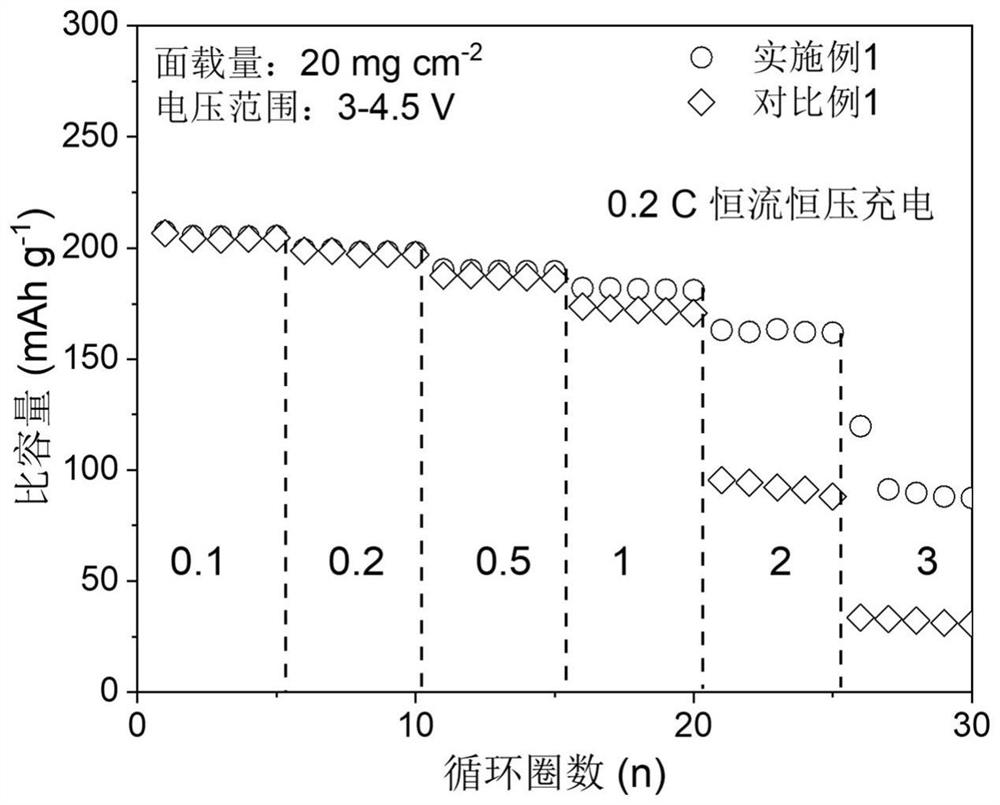

[0051] single crystal LiNi 7 co 1 mn 2 o 2 , Binder carboxymethyl cellulose, conductive agent KB800 and carbon fiber are dispersed in deionized water according to the mass ratio of 0.9:0.05:0.035:0.015 and mixed evenly in a Zhongyi disperser to obtain a mixed slurry. The solid content of the slurry is is 45wt.%. The prepared pole piece was coated with a loading capacity of 20 mg cm -2 . Put the wet pole piece in a low-temperature environment of -60°C and freeze it for 3 hours, then dry the pole piece at -10°C and a low pressure of 5 Pa for 12 hours, and then obtain a thick electrode with low tortuosity. And the pole piece was used for the characterization of electrochemical performance after rolling.

[0052] 2. Preparation of SEM samples

[0053] The pole pieces before and after rolling were prepared into SEM samples, and the morphology of the surface and cross section were observed respectively.

[0054] 3. Assemble the battery and test the electrochemical performanc...

Embodiment 2

[0059] The positive electrode material is polycrystalline LiNi 7 co 1 mn 2 o 2 , other conditions are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com