Silver-loaded antibacterial master batch and application thereof

A silver-loaded antibacterial and masterbatch technology, applied in the field of antibacterial materials, can solve problems such as migration, precipitation, and poor antibacterial durability of thin films, and achieve the effects of high silver loading, good antibacterial properties, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

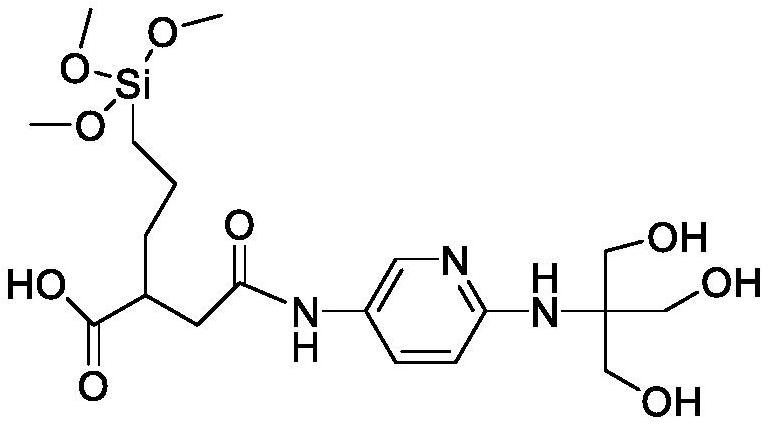

[0030] Preparation of silver-loaded hyperbranched polyester:

[0031] Step A: Stir 0.1mol trishydroxymethylaminomethane and 80mL methyl sulfoxide evenly, then add 0.1mol triethylamine, stir for 1h, then add 0.085mol 2-chloro-5-nitrate under nitrogen atmosphere The dimethyl sulfoxide solution of pyridine was heated to 80°C, and reacted for 4 hours. After the reaction was completed, the reaction was rotary evaporated under reduced pressure, washed with deionized water for several times, and dried to obtain the trihydric alcohol compound;

[0032] Step B. Mix 27g of iron powder, 100mL of ethanol, 20mL of deionized water and 3mL of 36wt% hydrochloric acid, heat to 85°C, activate for 20min, cool down to 40°C, add 50g of trihydric alcohol compound, heat up to 85°C, and stir for reaction 6h, stop the reaction, filter, adjust the pH value of the filtrate to 8 with ammonia water, let stand for 12h, filter with suction, precipitate the filtrate with deionized water, filter, and dry to o...

Embodiment 2

[0037] Preparation of silver-loaded hyperbranched polyester:

[0038] Step A: Stir 0.1mol of trishydroxymethylaminomethane and 80mL of methyl sulfoxide evenly, then add 0.1mol of triethylamine, stir for 2 hours, and then add 0.09mol of 2-chloro-5-nitrate under a nitrogen atmosphere The dimethyl sulfoxide solution of pyridine was heated to 90°C, and reacted for 4 hours, and the reaction was terminated, and the reaction was rotary evaporated under reduced pressure, washed with deionized water several times, and dried to obtain the trihydric alcohol compound;

[0039] Step B. Mix 30g of iron powder, 100mL of ethanol, 20mL of deionized water and 5mL of 36wt% hydrochloric acid, heat to 85°C, activate for 20min, cool down to 45°C, add 60g of trihydric alcohol compound, heat up to 80°C, and stir for reaction 6h, stop the reaction, filter, adjust the pH value of the filtrate to 8 with ammonia water, let stand for 12h, filter with suction, precipitate the filtrate with deionized water,...

Embodiment 3

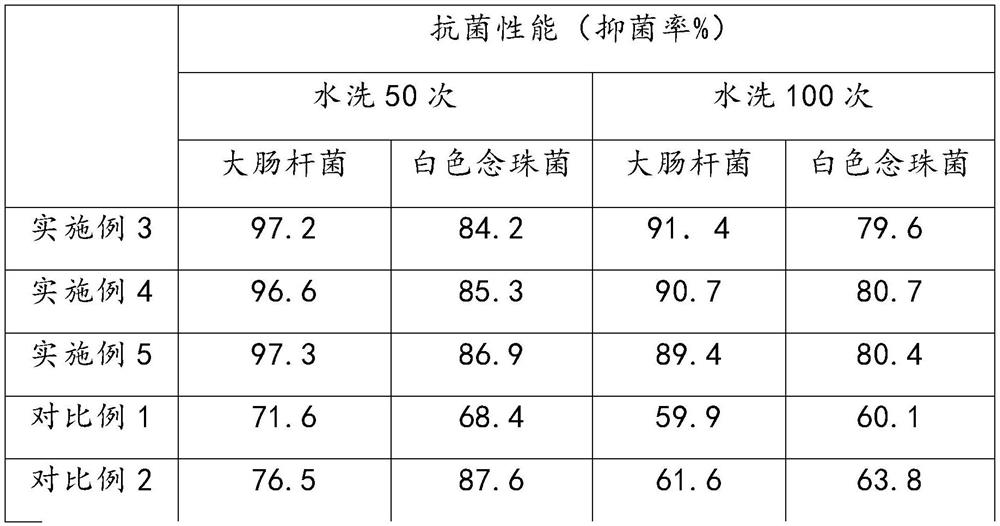

[0044] An antibacterial masterbatch:

[0045] Step 1, preparation comprises following raw material by weight: 15 parts of silver-loaded hyperbranched polyesters prepared in embodiment 1, 0.1 part of compatibilizer and 30 parts of carrier resins; Described compatibilizer is maleic anhydride grafted polyethylene; The carrier resin is polypropylene resin;

[0046] Step 2, mixing and granulating the silver-loaded hyperbranched polyester, a compatibilizer and a carrier resin to obtain an antibacterial masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com