Composite high-strength concrete

A concrete and high-strength technology, applied in the field of concrete, can solve problems such as poor durability, low compressive strength of high-strength concrete, and easy cracking, and achieve the effects of improving compactness, enhancing thermal insulation and heat resistance, and reducing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

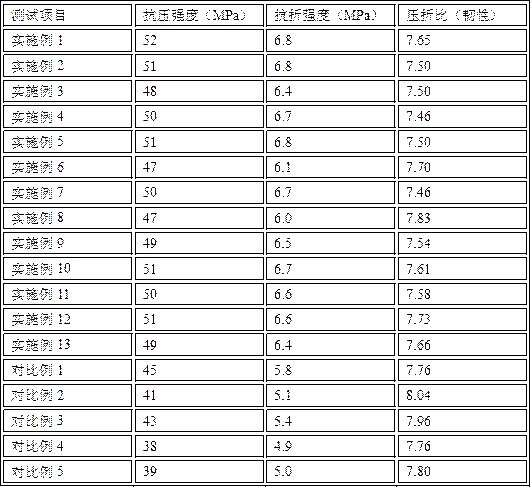

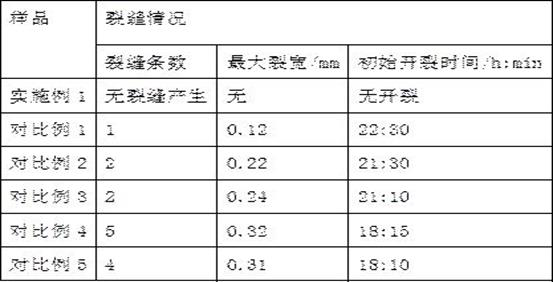

Examples

preparation example 1

[0041] (1) Soak 100 parts by weight of carbon fibers in absolute ethanol for 45 minutes, then ultrasonically clean them for 35 minutes, and then dry them in vacuum at 70°C for 4 hours;

[0042] (2) Mix the dried carbon fiber in step (1) with a hydrofluoric acid solution with a mass concentration of 35%, the volume ratio of the carbon fiber to the hydrofluoric acid solution is 1:2, heat and react at 70°C for 8 hours, take it out and use Wash with deionized water until neutral, and then vacuum-dry at a temperature of 70°C for 7 hours;

[0043] (3) Mix the carbon fibers dried in step (2) with the chitosan mixture at a weight ratio of 1:3, then wash with ethanol and deionized water, and dry in vacuum at 60°C for 5 hours to obtain modified carbon fibers.

preparation example 2

[0045] (1) Soak 100 parts by weight of carbon fiber in absolute ethanol for 30 minutes, then ultrasonically clean it for 45 minutes, and then vacuum dry it at 80°C for 3 hours;

[0046] (2) Mix the dried carbon fiber in step (1) with a hydrofluoric acid solution with a mass concentration of 25%, the volume ratio of the carbon fiber to the hydrofluoric acid solution is 1:2, heat and react at 60°C for 5 hours, take it out and use Wash with deionized water until neutral, then vacuum dry at 80°C for 6 hours;

[0047] (3) Mix the carbon fibers dried in step (2) with the chitosan mixture at a weight ratio of 1:5, then wash with ethanol and deionized water, and dry in vacuum at 70°C for 3 hours to obtain modified carbon fibers.

preparation example 3

[0049] (1) Soak 100 parts by weight of carbon fibers in absolute ethanol for 60 minutes, then ultrasonically clean them for 25 minutes, and then dry them in vacuum at 60°C for 5 hours;

[0050] (2) Mix the dried carbon fiber in step (1) with hydrofluoric acid solution with a mass concentration of 25-35%, the volume ratio of carbon fiber to hydrofluoric acid solution is 1:2, heat and react at 60°C for 12 hours, take out Afterwards, it was washed with deionized water to neutrality, and then vacuum-dried at a temperature of 80° C. for 6 hours to obtain modified carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com