Manufacturing method of multidirectional rib-containing aluminum alloy plate

A technology of aluminum alloy plate and manufacturing method, which is applied in the field of manufacturing multi-directional ribbed aluminum alloy plate, can solve the problems of difficulty in breaking through the manufacture of aluminum alloy plate with large height-thickness ratio, long manufacturing cycle, and high cost, so as to reduce the probability of buckling , Improve creep and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for manufacturing a multi-directional reinforced aluminum alloy plate, comprising the steps of:

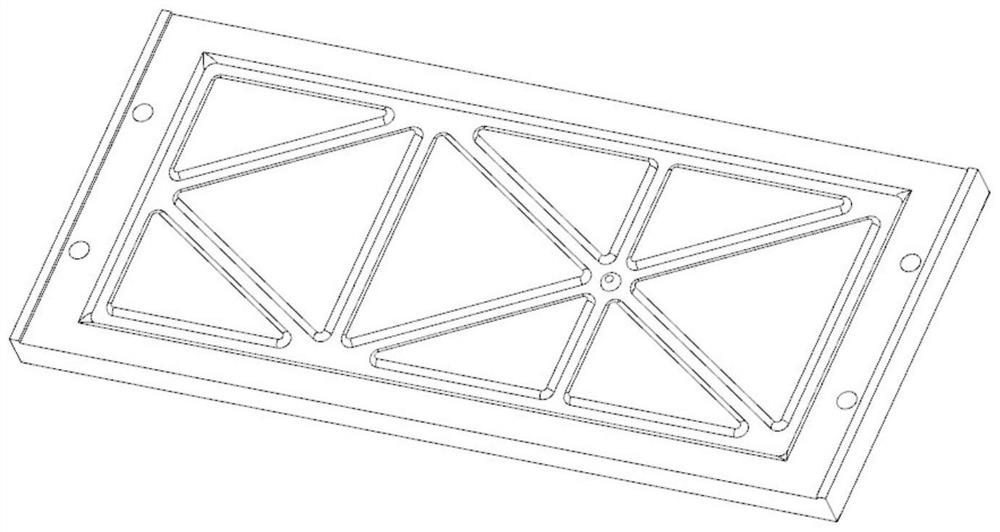

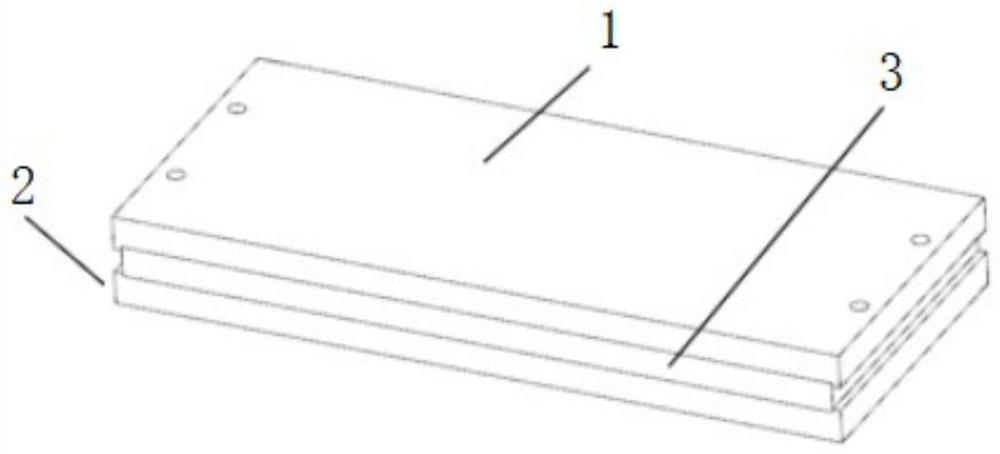

[0047] Step A, design and manufacture the upper mold and the lower mold according to the distribution of the required ribs on the aluminum alloy plate;

[0048] Step B. After heating the aluminum alloy plate to the recrystallization temperature for a certain period of time, place it between the upper mold and the lower mold for clamping;

[0049] Step C, placing the aluminum alloy plate, the upper mold and the lower mold that have been cooperatingly clamped in the middle of the rolls for rolling to obtain the aluminum alloy plate with ribs;

[0050] Step D, raising the height of the ribs by surfacing welding or additive manufacturing to obtain a ribbed aluminum alloy plate with a ratio of aluminum alloy plate thickness to rib height of 1:5-15;

[0051] Step E, performing creep aging forming treatment on the ribbed aluminum alloy plate with increased rib height.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com