Antibacterial activated carbon mask and preparation method thereof

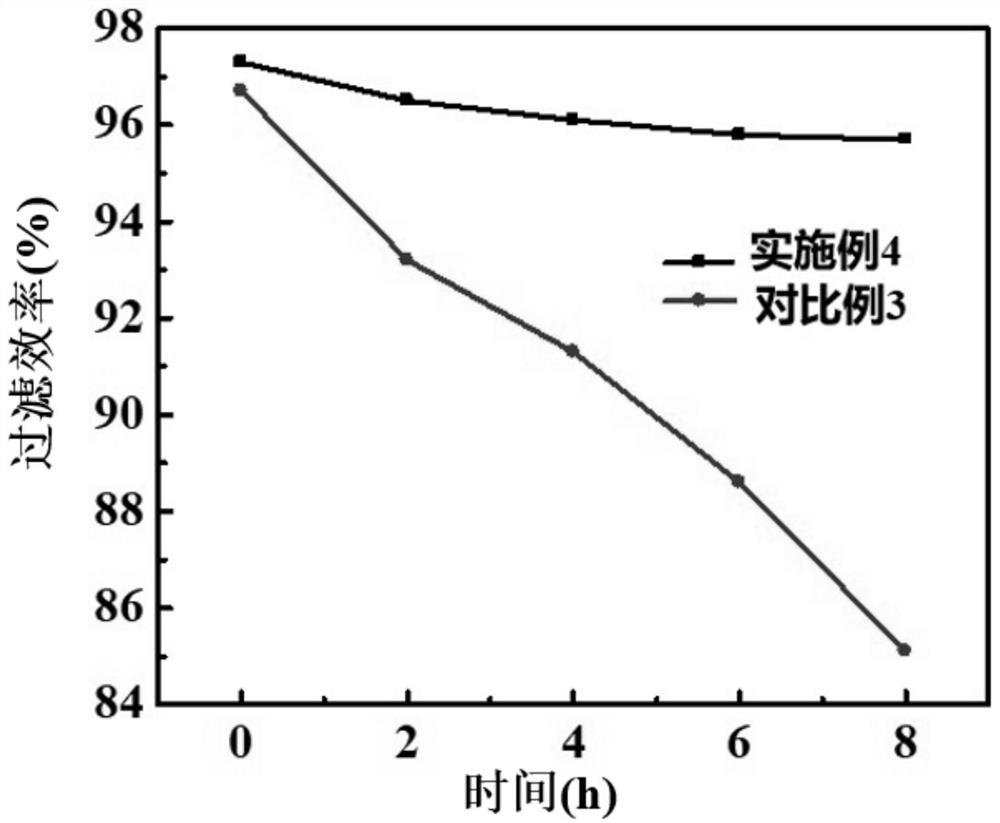

An activated carbon and mask technology, applied in the field of masks, can solve the problems of weak antibacterial effect, harsh reaction conditions, complicated preparation, etc., and achieve the effects of improving filtration efficiency, simple preparation process, and improving antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

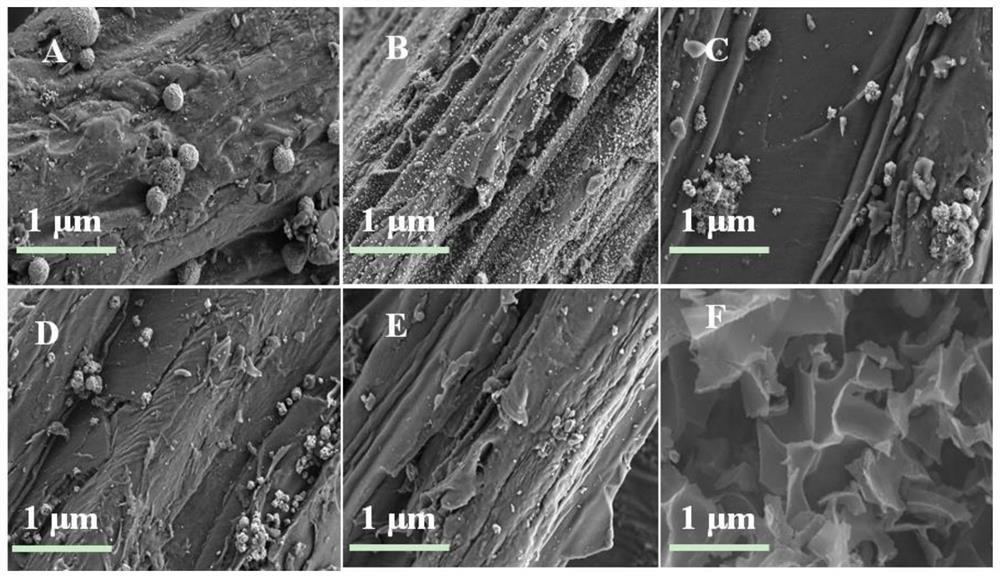

[0048] A preparation method of an antibacterial activated carbon mask, the steps are as follows: according to the preparation method of an ordinary mask, the outer layer of the photocatalyst melt-blown non-woven fabric, the inner layer of the activated carbon melt-blown non-woven fabric, and the surface layer of the pure cotton spunlace non-woven fabric are cut into The upper and lower heights are 95mm, and the left and right widths are 175mm. The outer layer of photocatalyst melt-blown non-woven fabric, the inner layer of activated carbon melt-blown non-woven fabric, and the surface layer of pure cotton spunlace non-woven fabric are stacked in order from top to bottom. ;Put the nose bridge strip at a distance of 8mm from the upper edge of the photocatalyst melt-blown non-woven fabric, and cover the nose bridge strip with non-woven fabric; place the two ear straps on the outer layer of the photocatalyst melt-blown non-woven fabric respectively Both ends, 5mm away from the upper...

Embodiment 2

[0058] A kind of preparation method of antibacterial active carbon mouth mask is basically consistent with embodiment 1, and its difference is only in:

[0059] The preparation method of described activated carbon melt-blown nonwoven inner layer is:

[0060] (1) Wash the discarded bamboo stalks and dry them at 90°C for 6 hours; then crush them and sieve them to obtain 325-mesh bamboo powder;

[0061] (2) Add 2g of copper nitrate trihydrate and 0.02g of hexamethylenetetramine to 150g of water and stir at a speed of 300r / min for 5min to form solution A; add 5g of bamboo powder in step (1) to solution A and soak for 12h ; After filtering, dry the insoluble matter at 80°C for 6h; then raise the temperature to 700°C in a nitrogen atmosphere at a heating rate of 5°C / min, keep it warm for 2h, and naturally cool to 25°C, wash the powder three times with water and acetone, Dry at ℃ for 6 hours, crush and sieve to obtain 325 mesh copper-doped activated carbon;

[0062] (3) 5g step (2)...

Embodiment 3

[0064] A kind of preparation method of antibacterial active carbon mouth mask is basically consistent with embodiment 1, and its difference is only in:

[0065] The preparation method of described activated carbon melt-blown nonwoven inner layer is:

[0066] (1) Wash the discarded bamboo stalks and dry them at 90°C for 6 hours; then crush them and sieve them to obtain 325-mesh bamboo powder;

[0067] (2) Add 2g of copper nitrate trihydrate and 0.02g of 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt into 150g of water and stir for 5min at a speed of 300r / min to form solution A; 5g of step ( 1) Bamboo powder was added to solution A and immersed for 12 hours; after filtration, the insoluble matter was dried at 80°C for 6 hours; then the temperature was raised to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere, kept for 2 hours, and naturally cooled to 25°C. ℃, the powder was washed three times with water and acetone, dried at 60 ℃ for 6 hours, crushed ...

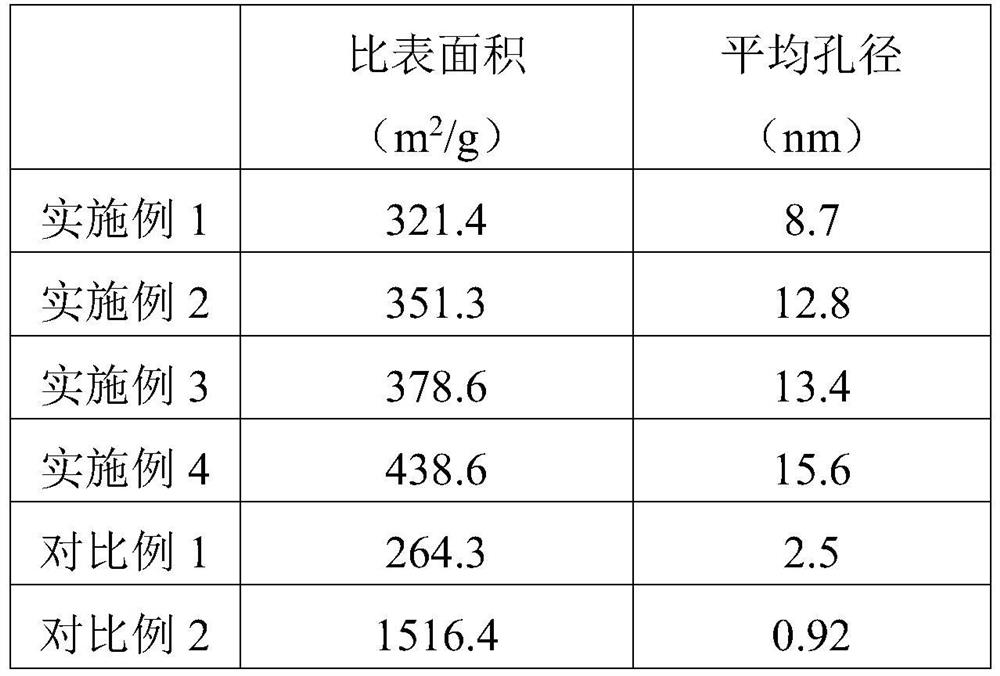

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com