Bismuth oxide-assisted zirconia-based electrolyte, and preparation method and application thereof

A zirconia-based, electrolyte technology, applied in the electrolysis process, electrolysis components, circuits, etc., can solve the problems of high sintering temperature and high content of scandium in the electrolyte, and achieve the effect of lowering the sintering temperature, reducing the scandium content, and uniform synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example provides a method for preparing a bismuth oxide-assisted zirconia-based electrolyte by using a sol-gel method, and the specific details are as follows:

[0033] S1: zirconium oxynitrate, scandium nitrate, bismuth nitrate, citric acid, ethylenediaminetetraacetic acid according to the target product (Sc 2 o 3 ) 0.06 (Bi 2 o 3 ) x (ZrO 2 ) 0.94–x The stoichiometric ratio of (x=0.01) was dissolved in 0.5mol / L nitric acid solution, heated to 90°C and stirred to make the water gradually volatilize to obtain a jelly;

[0034] S2: Dry the jelly obtained in S1 in an oven at 250°C to form a precursor powder;

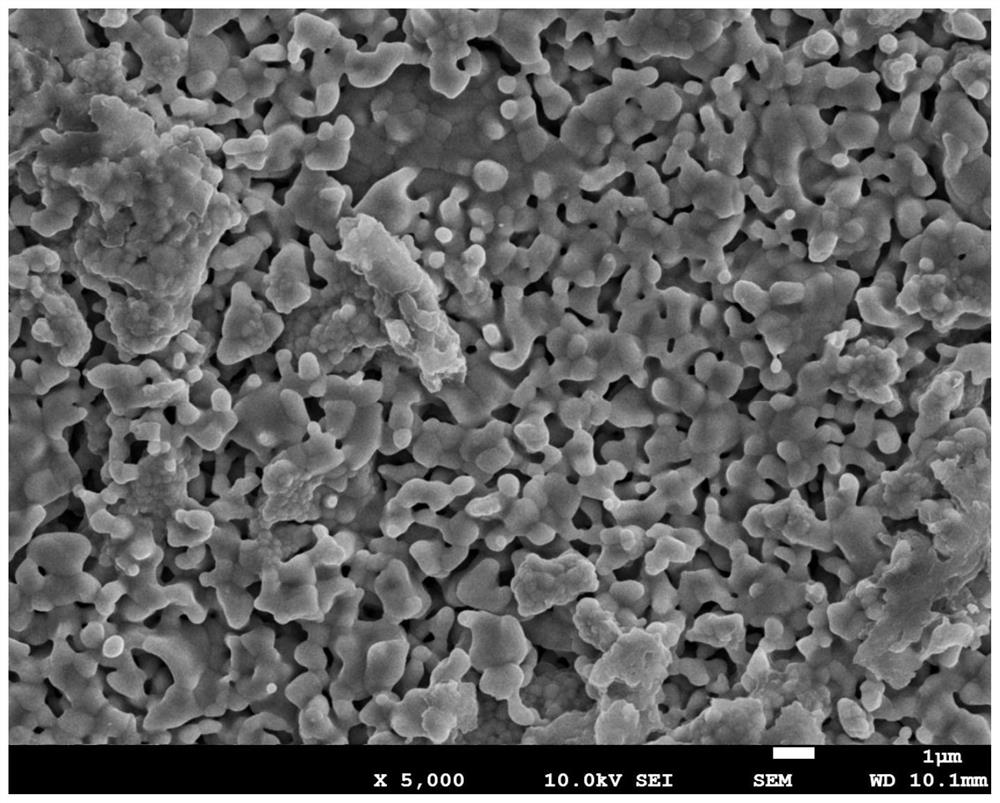

[0035] S3: Sintering the precursor obtained in step S2 at a constant temperature of 500° C. for 5 hours, further ball milling the sintered powder for 24 hours, and sieving the powder below 200 mesh to obtain bismuth oxide composite scandium oxide stabilized zirconia-based electrolyte powder;

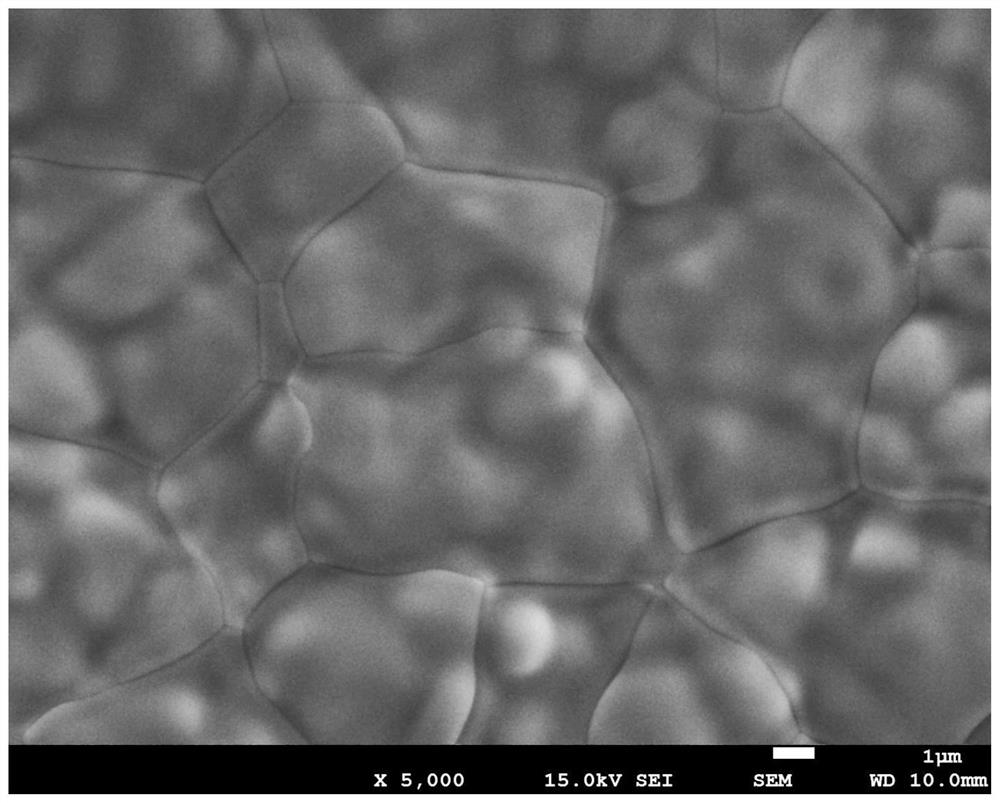

[0036] S4: Press the zirconia-based electrolyte powder obtai...

Embodiment 2

[0038] This example provides a method for preparing a bismuth oxide-assisted zirconia-based electrolyte by using a sol-gel method, and the specific details are as follows:

[0039] S1: zirconium oxynitrate, scandium nitrate, bismuth nitrate, citric acid, ethylenediaminetetraacetic acid according to the target product (Sc 2 o 3 ) 0.06 (Bi 2 o 3 ) x (ZrO 2 ) 0.94–x The stoichiometric ratio of (x=0.05) was dissolved in 1mol / L nitric acid solution, heated to 90°C and stirred to make the water gradually volatilize to obtain a jelly;

[0040] S2: Dry the jelly obtained in S1 in an oven at 250°C to form a precursor powder;

[0041] S3: Sintering the precursor obtained in step S2 at a constant temperature of 500° C. for 5 hours, further ball milling the sintered powder for 24 hours, and sieving the powder below 200 mesh to obtain bismuth oxide composite scandium oxide stabilized zirconia-based electrolyte powder;

[0042] S4: Press the zirconia-based electrolyte powder obtaine...

Embodiment 3

[0044] This example provides a method for preparing a bismuth oxide-assisted zirconia-based electrolyte by using a sol-gel method, and the specific details are as follows:

[0045] S1: zirconium oxynitrate, scandium nitrate, bismuth nitrate, citric acid, ethylenediaminetetraacetic acid according to the target product (Sc 2 o 3 ) 0.06 (Bi 2 o 3 ) x (ZrO 2 ) 0.94–x The stoichiometric ratio of (x=0.1) is dissolved in 1.5 mol / L nitric acid solution, wherein scandium oxide and bismuth oxide are added in a molar ratio of 90:10, heated to 90°C and stirred to gradually volatilize the water to obtain a jelly ;

[0046] S2: Dry the jelly obtained in S1 in an oven at 250°C to form a precursor powder;

[0047]S3: Sintering the precursor obtained in step S2 at a constant temperature of 500° C. for 5 hours, further ball milling the sintered powder for 24 hours, and sieving the powder below 200 mesh to obtain bismuth oxide composite scandium oxide stabilized zirconia-based electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com