Magnetic conductive nano-metal/carbon aerogel wave absorbing material and preparation method thereof

A carbon aerogel and wave absorbing material technology, applied in electrical components, antennas, etc., can solve the problems of rare reports, complicated material design and synthesis, and achieve the effect of low density, high specific surface area, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

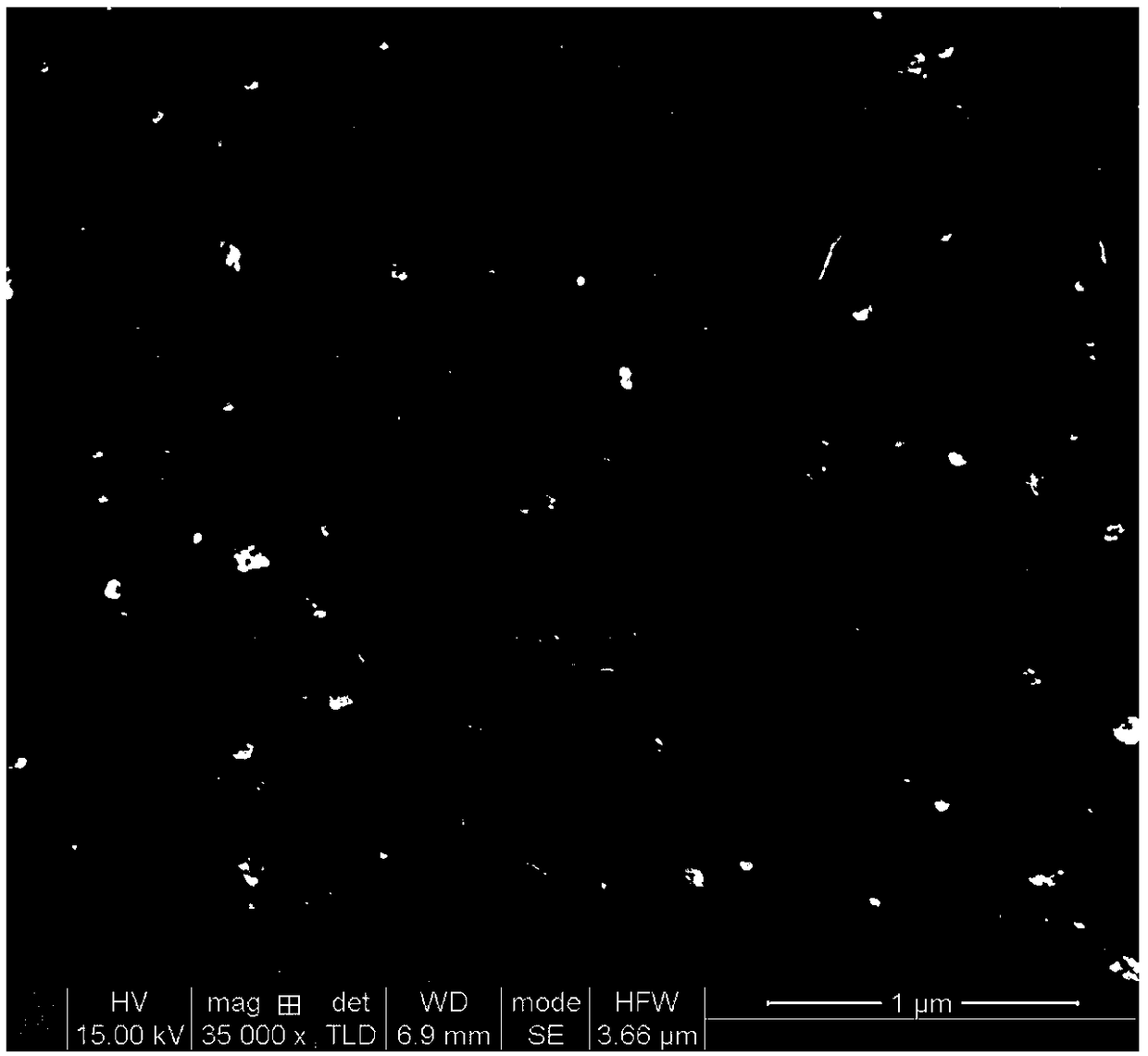

Image

Examples

Embodiment 1

[0033] Step 1. Mix 8.08g resorcinol and formaldehyde at a molar ratio of 1:2 and stir mechanically until clarified. Use 0.2mol L -1 The volume of the solution was adjusted to 100ml with NaOH solution, and a wet gel was obtained after 3 days of gelation at room temperature. Acid aging of wet gels, solvent exchange, CO 2 After supercritical fluid drying, resorcinol-formaldehyde airgel is obtained, and the airgel is further carbonized, heated to 1050°C at a heating rate of 1.5°C / min, and resorcinol-formaldehyde carbon gas is obtained after constant temperature for 2 hours gel.

[0034] Step 2. Weigh 0.05g PdCl 2 In a beaker, add 45mL EtOH and 5mL 1mol·L -1 HCl is placed in an ultrasonic cleaner for ultrasonic dissolution, and the resorcinol-formaldehyde carbon airgel in step 1 is placed in the above PdCl 2 Take it out after 1 day in the activation solution, rinse with deionized water to remove the PdCl enriched on the surface of the hydrogel 2 , and then placed in the electr...

Embodiment 2

[0038] Step 1. Mix 8.08g of phenol and formaldehyde at a molar ratio of 1:2, stir mechanically until clear, and use 0.2mol·L - 1 Dilute the solution to 100mL with NaOH solution, gel at room temperature for 3 days to obtain a wet gel, pickle and age the wet gel, solvent exchange, CO 2 After the supercritical fluid is dried, the phenol-formaldehyde airgel is obtained, and the airgel is further carbonized, heated to 1050°C at a heating rate of 1.5°C / min, and the phenol-formaldehyde carbon airgel is obtained after constant temperature for 2 hours;

[0039] Step 2. Weigh 0.05g PdCl 2 In a beaker, add 45mL EtOH and 5mL 1mol·L -1 HCl is placed in an ultrasonic cleaner for ultrasonic dissolution, and the phenol-formaldehyde carbon airgel in step 1 is placed in the above-mentioned PdCl 2 Take it out after 1 day in the activation solution, rinse with deionized water to remove the PdCl enriched on the surface of the hydrogel 2 , and then placed in the electroless nickel plating solut...

Embodiment 3

[0043] Step 1. Mix 8.08g of phenol and formaldehyde at a molar ratio of 1:2, stir mechanically until clear, and use 0.2mol·L - 1 Dilute the solution to 100ml with NaOH solution, and get a wet gel after gelling at room temperature for 3 days; pickling and aging the wet gel, solvent exchange, CO 2 After the supercritical fluid is dried, the phenol-formaldehyde airgel is obtained, and the airgel is further carbonized, heated to 1050°C at a heating rate of 1.5°C / min, and the phenol-formaldehyde carbon airgel is obtained after constant temperature for 2 hours;

[0044] Step 2. Weigh 0.05g PdCl 2 In a beaker, add 45mL EtOH and 5mL 1mol·L -1 HCl is placed in an ultrasonic cleaner for ultrasonic dissolution, and the phenol-formaldehyde carbon airgel in step 1 is placed in the above-mentioned PdCl 2 Take it out after 1 day in the activation solution, rinse with deionized water to remove the PdCl enriched on the surface of the hydrogel 2 , and then placed in an electroless nickel pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com