Resilient magnetic carbon foam and preparation method thereof

A magnetic carbon and foam technology, which is used in the preparation/purification of carbon, ceramic products, other household appliances, etc., can solve the problems of rare reports, and achieve the effects of excellent loss capacity, low density and suitable electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

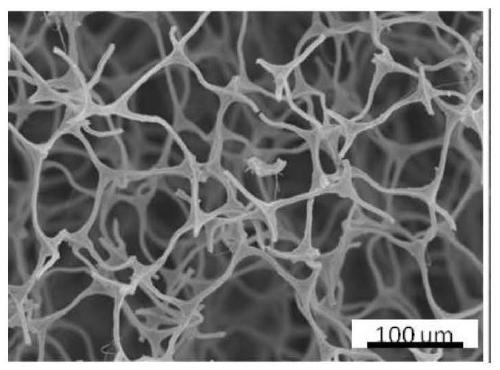

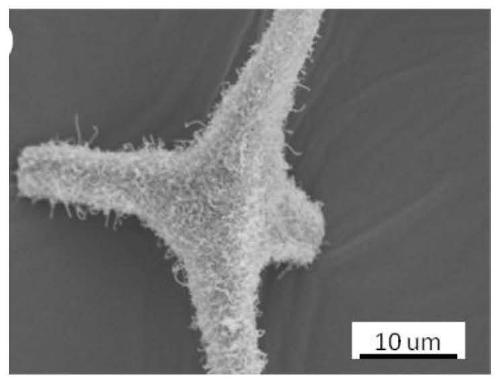

Image

Examples

Embodiment 1

[0038] A preparation method of resilient magnetic carbon foam, comprising the following steps:

[0039] Step 1. Put 3×3×3cm 3 The melamine foam was ultrasonically cleaned three times in absolute ethanol and deionized water, and then dried in an oven at 60°C to constant weight;

[0040] Step 2, immerse the melamine foam treated in step 1 in a cobalt acetate solution with a mass percentage concentration of 1% for 24 hours; then squeeze repeatedly to remove the remaining cobalt acetate solution in the foam, and then use deionized water to clean the foam to Removal of Co not complexed with melamine foam 2+ ;

[0041] Step three, the Co obtained in step two 2+ The metal ion complex foam is carbonized and pyrolyzed in a tube furnace under the protection of argon to prepare resilient magnetic carbon foam;

[0042] The procedure for carbonization pyrolysis in a tube furnace consists of the following steps:

[0043] Step 1. Repeatedly evacuate and fill the tube furnace with argon to...

Embodiment 2

[0049] A preparation method of resilient magnetic carbon foam, comprising the following steps:

[0050] Step 1. Put 3×3×3cm 3 The melamine foam was ultrasonically cleaned three times in absolute ethanol and deionized water, and then dried in an oven at 60 °C to constant weight.

[0051] Step 2, immerse the melamine foam treated in step 1 in a cobalt acetate solution with a mass percentage concentration of 1% for 24 hours; then squeeze repeatedly to remove the remaining cobalt acetate solution in the foam, and then use deionized water to clean the foam to Removal of Co not complexed with melamine foam 2+ ;

[0052] Step three, the Co obtained in step two 2+ The metal ion complex foam is carbonized and pyrolyzed in a tube furnace under the protection of argon to prepare resilient magnetic carbon foam;

[0053] The procedure for carbonization pyrolysis in a tube furnace consists of the following steps:

[0054] Step 1. Repeatedly evacuate and fill the tube furnace with argon...

Embodiment 3

[0060] A preparation method of resilient magnetic carbon foam, comprising the following steps:

[0061] Step 1. Put 3×3×3cm 3 The melamine foam was ultrasonically cleaned three times in absolute ethanol and deionized water, and then dried in an oven at 70 °C to constant weight.

[0062] Step 2, immerse the melamine foam treated in step 1 in a 1% cobalt acetate solution for 36 hours; then squeeze repeatedly to remove the remaining cobalt acetate solution in the foam, and then use deionized water to clean the foam to Removal of Co not complexed with melamine foam 2+ ;

[0063] Step three, the Co obtained in step two 2+ The metal ion complex foam is carbonized and pyrolyzed in a tube furnace under the protection of argon to prepare resilient magnetic carbon foam;

[0064] The procedure for carbonization pyrolysis in a tube furnace consists of the following steps:

[0065] Step 1. Repeatedly evacuate and fill the tube furnace with argon to ensure that the air is completely re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical bandwidth | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com