Preparation process of copper-clad aluminum flat wire drawn and rolled by die

A copper-clad aluminum flat wire and a preparation process technology, which is applied in the manufacture of wire harnesses, etc., can solve the problems of easy cracking and cracking of wire rods, and achieve the effects of preventing copper strips from being scratched, preventing crushing, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

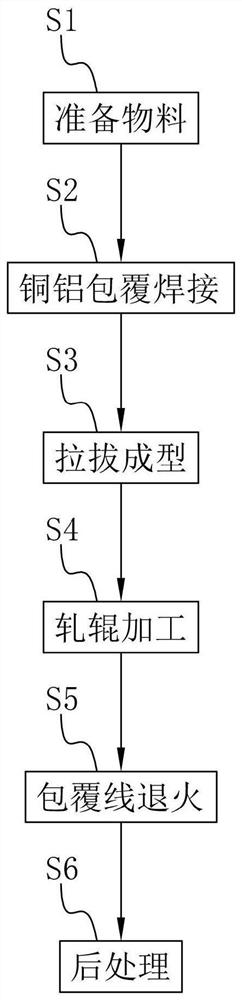

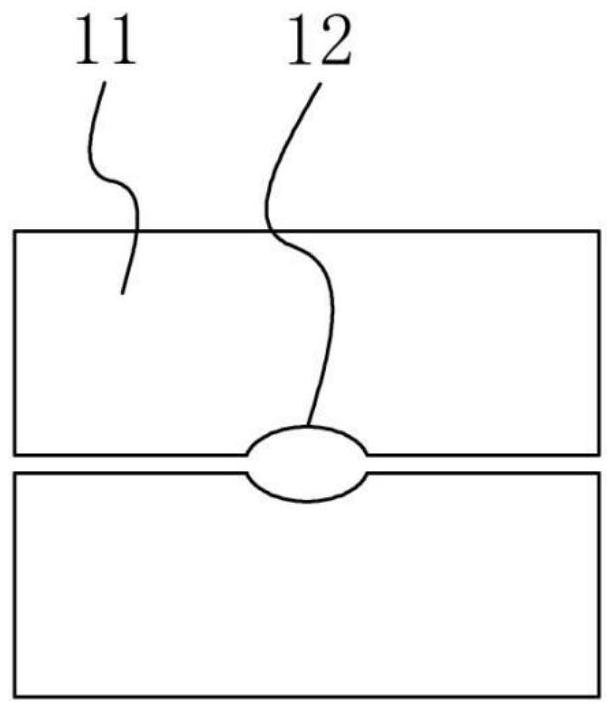

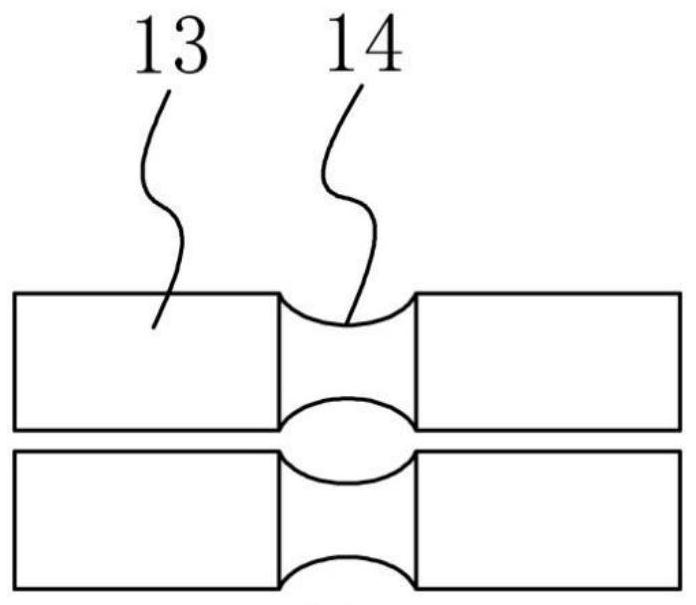

[0053] refer to figure 1 , figure 2 and image 3 , a preparation process of copper-clad aluminum flat wire drawn and rolled by a die, comprising the following steps:

[0054] S1. Prepare materials: preset aluminum core and copper strip for standby, the overall cross-section of the aluminum core is elliptical, roll the aluminum core with a roll with an elliptical abutment surface on the rolling mill, and squeeze it through the elliptical abutment surface Aluminum core, so that the overall cross section of the aluminum core is elliptical, the ratio of the short axis to the long axis of the aluminum core cross section is 1:3 to 1:5, and the aluminum core with an overall elliptical cross section is treated in an inert atmosphere. Annealing treatment, in the annealing treatment of the aluminum core, the annealing temperature is 330-350°C, and the annealing holding time is 2 hours; the thickness of the aluminum core is greater than the thickness of the copper strip, and the coppe...

Embodiment 2

[0077] A preparation process of copper-clad aluminum flat wire drawn and rolled by a die, comprising the following steps:

[0078] S1. Prepare materials: preset aluminum core and copper strip for standby, the overall cross-section of the aluminum core is elliptical, roll the aluminum core with a roll with an elliptical abutment surface on the rolling mill, and squeeze it through the elliptical abutment surface Aluminum core, so that the overall cross-section of the aluminum core is elliptical, the ratio of the short axis to the long axis of the aluminum core cross-section is 1:4, and the aluminum core with an overall elliptical cross-section is annealed in an inert atmosphere. In the annealing treatment of the aluminum core, the annealing temperature is 350°C, and the annealing holding time is 2 hours; the thickness of the aluminum core is greater than that of the copper strip, and the copper sheet is made of red copper, which has the advantages of good conductivity and high ha...

Embodiment 3

[0085] A preparation process of copper-clad aluminum flat wire drawn and rolled by a die, comprising the following steps:

[0086] S1. Prepare materials: preset aluminum core and copper strip for standby, the overall cross-section of the aluminum core is elliptical, roll the aluminum core with a roll with an elliptical abutment surface on the rolling mill, and squeeze it through the elliptical abutment surface Aluminum core, so that the overall cross-section of the aluminum core is elliptical, the ratio of the short axis to the long axis of the aluminum core cross-section is 1:4, and the aluminum core with an overall elliptical cross-section is annealed in an inert atmosphere. In the annealing treatment of the aluminum core, the annealing temperature is 350°C, and the annealing holding time is 2 hours; the thickness of the aluminum core is greater than that of the copper strip, and the copper sheet is made of red copper, which has the advantages of good conductivity and high ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com