Urea box casting bracket assembly

A urea tank and casting technology, applied in engine components, mufflers, machines/engines, etc., can solve the problems of inconvenient bundling and urea filling of urea injection pipes, and achieve the effects of light weight, continuous design, and optimized layout space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

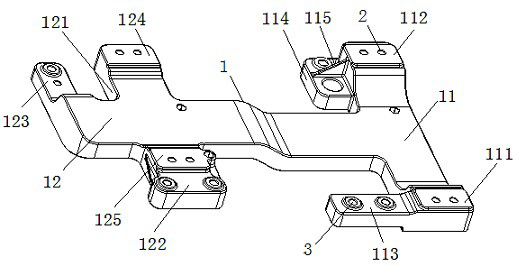

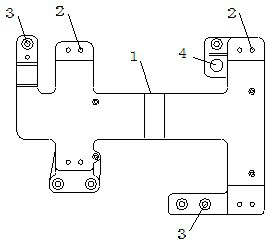

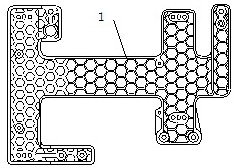

[0022] Such as figure 1 , figure 2 , image 3 As shown, the urea tank casting bracket assembly of the present invention includes a casting body 1 , and a urea tank assembly hole 2 , a girder bracket assembly hole 3 , an installation hole 4 and a plurality of installation process holes provided on the casting body 1 .

[0023] The casting body 1 includes a base portion 11 and a connecting portion 12;

[0024] The base 11 is in a T-shaped structure, and a first boss 111 and a second boss 112 are respectively upwardly formed from the lateral ends of the base 11, and the upper end faces of the first boss 111 and the second boss 112 are located on the same horizontal plane; One side of the table 111 extends out a strip-shaped extension 113 along the longitudinal extension direction of the base 11; Out of the first sunken step 114, a connecting rib 115 is provided between the upper end surface of the first sunken step 114 and the second boss 112;

[0025] The connecting part 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com