Organic pouring sealant as well as preparation method and application thereof

A potting, organic technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of decreased mechanical properties, easy generation of bubbles, affecting the light output rate of LEDs, etc., to improve the hydrophobic performance, The effect of improving mechanical properties and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The preparation method of amino-modified graphene in the embodiment of the present invention comprises the following steps:

[0083] S1: Exfoliate 100 parts of graphite powder (CAS No.: 7782-42-5, Aladdin) by supercritical carbon dioxide method (pressure 20 MPa, temperature 40 ° C), add 500 parts of water to the obtained graphite powder, and obtain a slurry The material is crushed through a homogenizer. The pressure of the homogenizer is 80MPa. After the crushing is completed, it is processed by a composite dispersion method of ultrasound, shearing and emulsification. After the dispersion is completed, it is spray-dried at a drying temperature of 150°C and the dried product is collected;

[0084] Add the dried product to 100 parts of dilute hydrochloric acid for soaking at -10°C, and then add the compound of potassium permanganate and hydrogen peroxide after 4 hours, wherein 10 parts of potassium permanganate and 10 parts of hydrogen peroxide are used, and the temperatur...

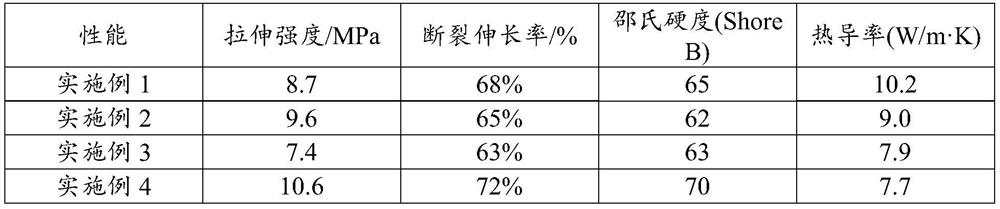

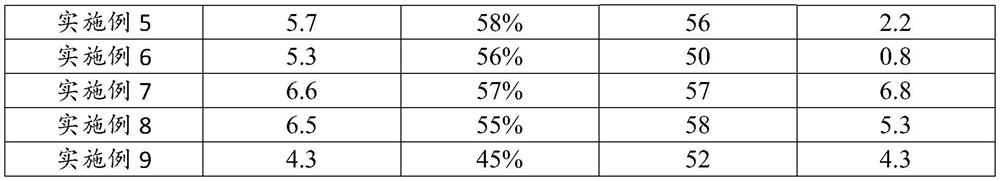

Embodiment 1

[0093] This embodiment is an organic potting compound and its preparation method.

[0094] The organic potting compound of this embodiment is composed of the following preparation raw materials in parts by weight:

[0095] Polysiloxane (CAS No.: 68083-19-2; vinyl-terminated polydimethylsiloxane, viscosity 500mPa·s, molecular weight 17200, vinyl content 0.37wt% ~ 0.43wt%, Hubei Handafei Biology Technology Co., Ltd.) 25 copies;

[0096] 5 parts of amino-modified graphene;

[0097] Thermally conductive filler (obtained by mixing surface-modified alumina and surface-modified aluminum nitride, the mass ratio of surface-modified alumina and surface-modified aluminum nitride is 2:1) 30 parts;

[0098] Fluorine-terminated vinyl silane (CAS number: 211985-86-3; vinyl (trifluoromethyl) dimethyl silane, fluorine content: 36.9 wt%, vinyl content: 17.5 wt%) 20 parts;

[0099] 3 parts of crosslinking agent (polymethylhydrogensiloxane, CAS number: 63148-57-2);

[0100] Catalyst (platinum...

Embodiment 2

[0107] This embodiment is an organic potting compound and its preparation method.

[0108] The organic potting compound of this embodiment is composed of the following preparation raw materials in parts by weight:

[0109] Polysiloxane (CAS No.: 68083-19-2; vinyl-terminated polydimethylsiloxane, viscosity 500mPa·s, molecular weight 17200, vinyl content 0.37wt% ~ 0.43wt%, Hubei Handafei Biology Technology Co., Ltd.) 25 copies;

[0110] 3 parts of amino-modified graphene;

[0111] Thermally conductive filler (obtained by mixing surface-modified alumina and surface-modified aluminum nitride, the mass ratio of surface-modified alumina and surface-modified aluminum nitride is 2:1) 30 parts;

[0112] Fluorine-terminated vinyl silane (CAS number: 211985-86-3; vinyl (trifluoromethyl) dimethyl silane, fluorine content: 36.9 wt%, vinyl content: 17.5 wt%) 10 parts;

[0113] 3 parts of crosslinking agent (polymethylhydrogensiloxane, CAS number: 63148-57-2);

[0114] Catalyst (platinum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com