Modified ternary positive electrode material, preparation method thereof and lithium ion battery

A cathode material and modification technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as poor structural stability and poor high-temperature cycle performance, and achieve improved electrical conductivity, improved structural stability and Lithium intercalation reversibility and the effect of reducing the shuffling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

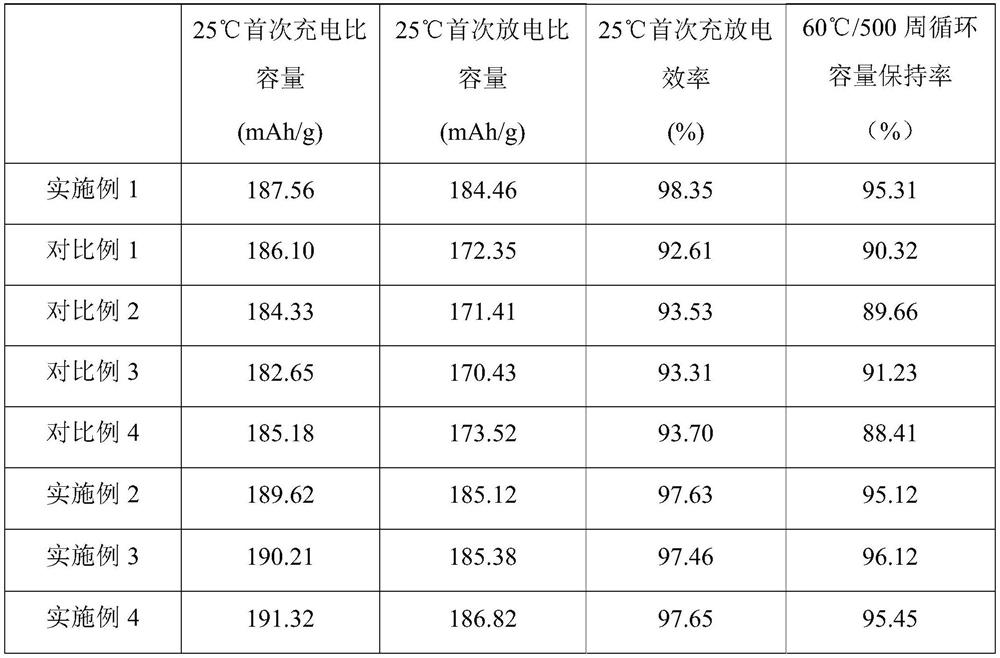

Examples

preparation example Construction

[0026] The first aspect of the present invention provides a modified ternary positive electrode material and a preparation method thereof, which mainly includes the following steps:

[0027] S100, preparing calcined material

[0028] Specifically, after mixing nickel-cobalt-manganese hydroxide and boric acid uniformly, pre-sintering is carried out to obtain pre-sintered material; The precursor of the nickel-cobalt-manganese ternary cathode material is not particularly limited, and its composition is Ni x co y mn 1-x-y (OH) 2 , where 0.3≤x≤0.8, 0≤y≤0.3. By mixing boric acid with the precursor and then pre-sintering, the boric acid is decomposed into boron oxide and then melted and doped into the precursor at high temperature, and pre-sintered with the precursor to better combine, improving the structural stability and reversibility of lithium intercalation. In one or more embodiments of the present invention, the quality of boric acid is 0.1%-1% of the quality of the nic...

Embodiment 1

[0037] The ternary positive electrode material in this embodiment uses boron-doped nickel-cobalt-manganese ternary positive electrode material as the base material, and introduces titanium ion doping at the same time, forming a lithium fluoride coating layer on its surface. The specific preparation steps are as follows:

[0038] Take 100g of NCM523 precursor (D50 = 5.43μm) and 0.13g of boric acid, mix them evenly, put them into a box furnace, raise the temperature to 600°C at a heating rate of 5°C / min and keep it warm for 6h, during which the air flow rate is 200ml / min , after the sintering is completed, the temperature is naturally lowered to obtain the pre-fired material;

[0039]Take 50g of the pre-fired material, mix it with 22g of battery-grade lithium carbonate and 0.2g of titanium dioxide, and then put it into the furnace, raise the temperature to 800°C at a heating rate of 5°C / min and keep it for 6 hours, then increase the temperature at 2°C / min Raise the temperature t...

Embodiment 2

[0059] The ternary positive electrode material in this embodiment uses boron-doped nickel-cobalt-manganese ternary positive electrode material as the base material, and introduces titanium ion doping at the same time, forming a lithium fluoride coating layer on its surface. The specific preparation steps are as follows:

[0060] Take 100g of NCM523 precursor (D50 = 4.03μm) and 0.16g of boric acid, mix them evenly, put them into a box furnace, raise the temperature to 650°C at a heating rate of 5°C / min and keep it warm for 6h, during which the air flow rate is 200ml / min , after the sintering is completed, the temperature is naturally lowered to obtain the pre-fired material;

[0061] Take 50g of the pre-fired material, mix it with 23g of battery-grade lithium carbonate and 0.22g of titanium dioxide, and then put it into the furnace, raise the temperature to 800°C at a heating rate of 5°C / min and keep it for 6 hours, then increase the temperature at 2°C / min Raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com