Calcium phosphate coated high-nickel ternary positive electrode material as well as preparation method and application thereof

A positive electrode material, calcium phosphate technology, applied in the field of electrochemistry, can solve the problems of poor cycle stability of high-nickel ternary positive electrode materials, achieve good cycle stability, simple preparation method, and improve storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Based on the above strategy, an embodiment of the present invention provides a method for preparing a calcium phosphate-coated high-nickel ternary cathode material, including the following steps:

[0037] S1, prepare calcium source solution and phosphorus source solution;

[0038] S2. Add calcium source solution into organic solvent or water, stir evenly, then add high-nickel ternary cathode material and phosphorus source solution, heat and dry to obtain powder;

[0039] S3. Calcining the powder to obtain a calcium phosphate-coated high-nickel ternary positive electrode material.

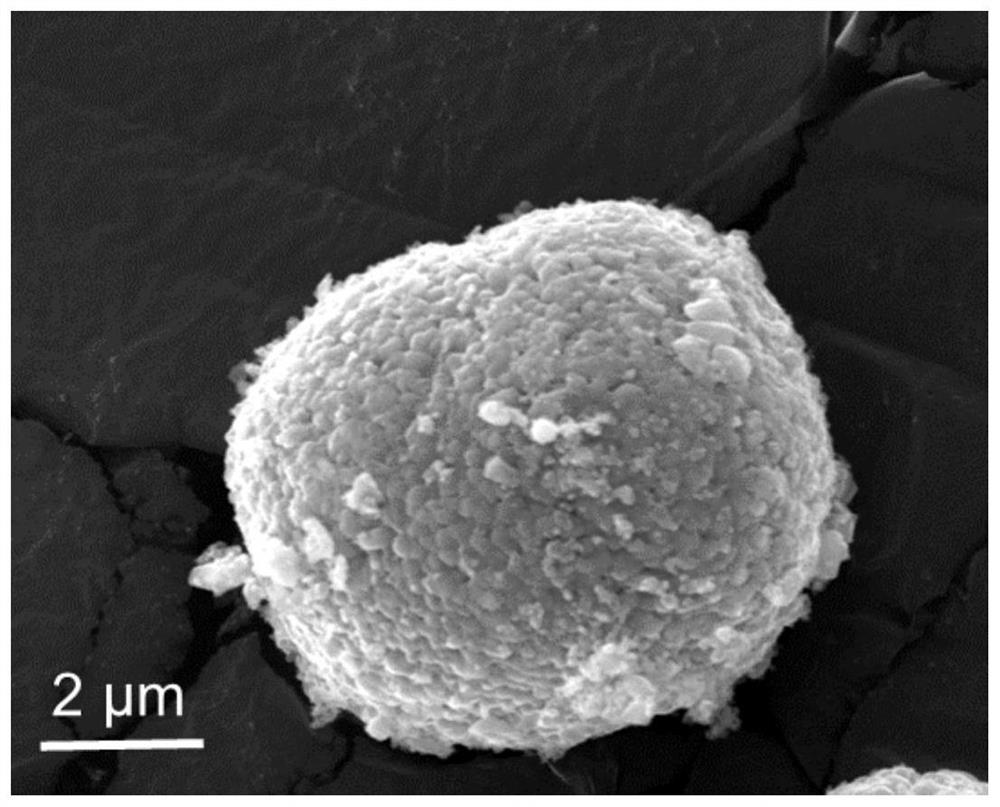

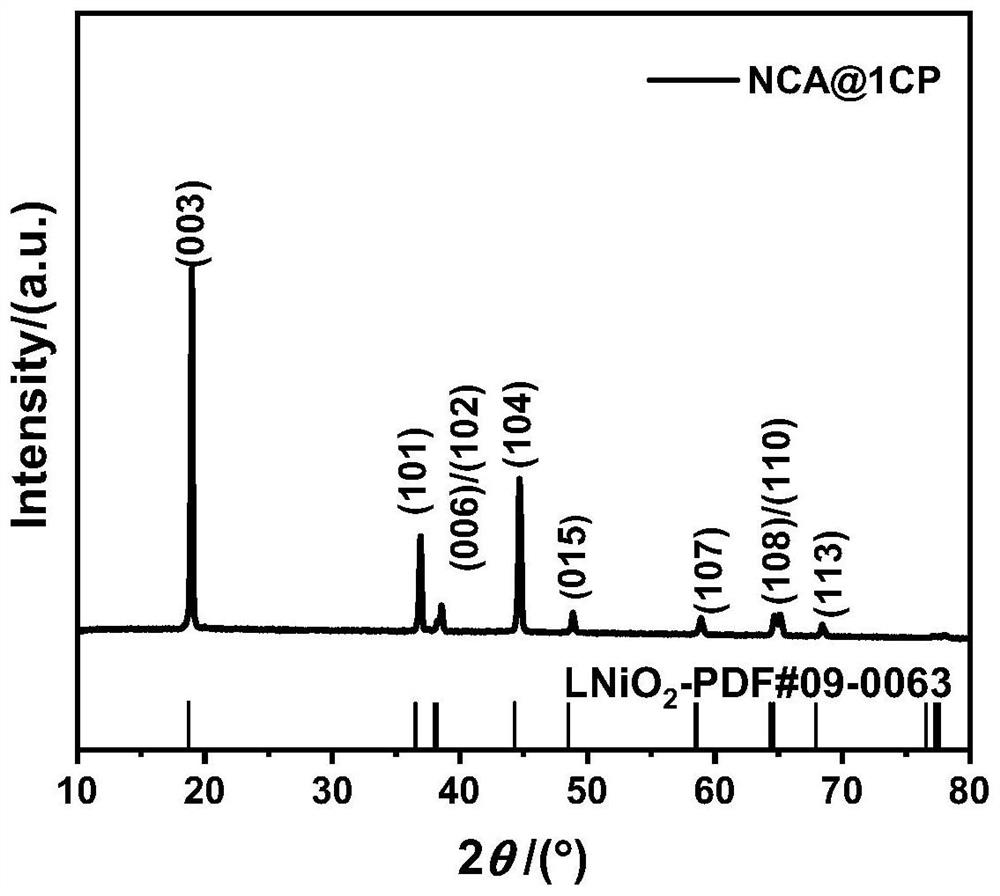

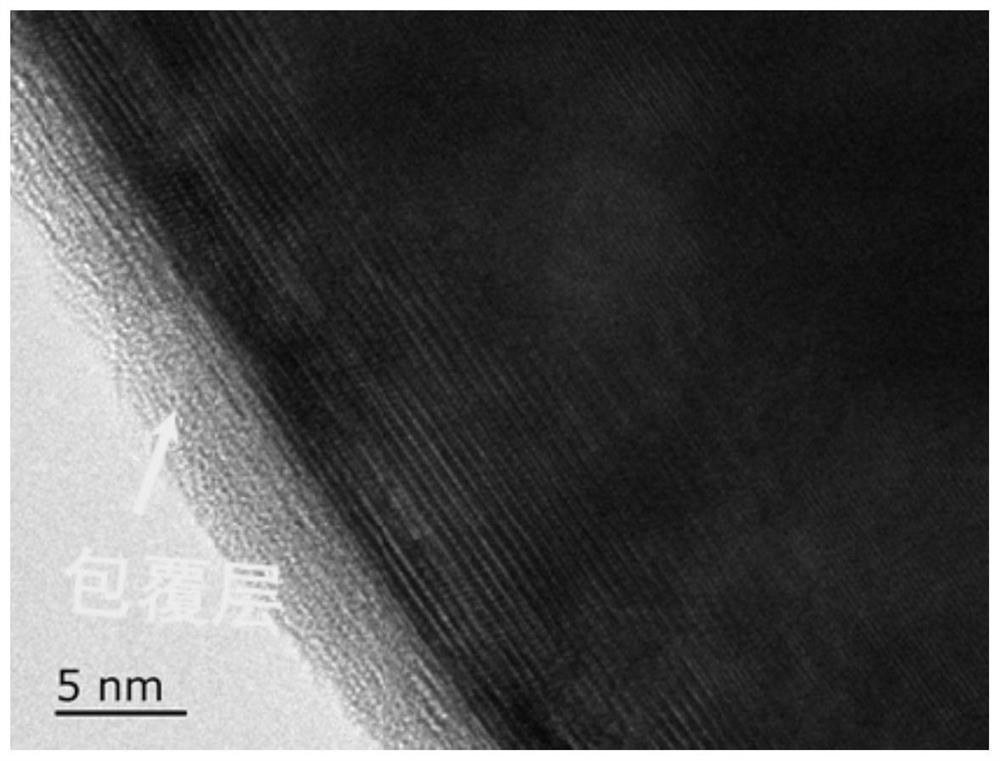

[0040] Thus, the present invention forms a passivation layer on the surface after coating calcium phosphate on the high-nickel ternary positive electrode material through calcination. Since calcium phosphate has excellent thermal stability and excellent chemical stability, its Coating on the high-nickel ternary surface can effectively reduce the residual lithium on the surface of the high-ni...

Embodiment 1

[0056] This embodiment provides a method for preparing a calcium phosphate-coated high-nickel ternary positive electrode material, comprising the following steps:

[0057] 1) Weigh 2.28407g (0.009672115mol) of calcium nitrate tetrahydrate (relative molecular weight 236.15), dissolve it in ethanol, pour it into a 100ml volumetric flask, add ethanol to constant volume, and weigh 0.741722g (0.00644807mol) of ammonium dihydrogen phosphate (relative molecular mass 115.03), dissolved in ultrapure water, poured into a 100ml volumetric flask, and added water to volume.

[0058] According to the coating amount of calcium phosphate is 0.5wt%, carry out batching, calcium-phosphorus ratio 3:2 (0.5 milliliter calcium nitrate adds 0.5 milliliter ammonium dihydrogen phosphate mixes, obtains 0.5wt% calcium phosphate coating required on the high-nickel material The proportioning ratio, that is, mixing 0.5ml each of two different solutions is 0.5wt% coating amount. When 1ml each of the two diff...

Embodiment 2

[0062] This embodiment provides a method for preparing a calcium phosphate-coated high-nickel ternary positive electrode material, comprising the following steps:

[0063] 1) Weigh 2.28407g (0.009672115mol) of calcium nitrate tetrahydrate (relative molecular weight 236.15), dissolve it in ethanol, pour it into a 100ml volumetric flask, add ethanol to constant volume, and weigh 0.741722g (0.00644807mol) of ammonium dihydrogen phosphate (relative molecular mass 115.03), dissolved in ultrapure water, poured into a 100ml volumetric flask, and added water to volume.

[0064] According to the coating amount of calcium phosphate is 1wt%, the compounding is carried out, and the ratio of calcium and phosphorus is 3:2.

[0065] 2) Add 1ml of calcium nitrate solution into 100ml of ethanol, stir evenly, take 1g of high-nickel ternary material, add 1ml of ammonium dihydrogen phosphate solution, stir slowly, heat and stir at 80°C for 50min, stir and evaporate to dryness to obtain powder; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com