A kind of preparation method of single crystal ternary cathode material

A cathode material and single crystal technology, which is applied in the field of single crystal ternary cathode material preparation, can solve the problems of structural lithium extraction, excessive by-product gas, increase experimental complexity, etc., and achieve thermal stability improvement, capacity and voltage improvement. , the effect of improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

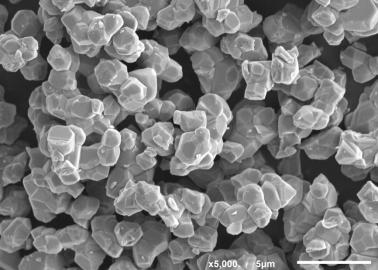

[0028] A method for preparing a single crystal ternary positive electrode material, comprising the following steps:

[0029] S1: Mix lithium oxide with three oxides of nickel, cobalt and manganese in proportion and ball mill; the mass ratio of Li:Ni:Co:Mn is (1.02~1.12):(0.75~0.95):(0.01~0.10): (0.02~0.20), the high nickel content ensures that the capacity of the positive electrode material is high enough. Nickel oxides are NiO, Ni 3 o 4 , NiO 2 、Ni 2 o 3 At least one of the cobalt oxides is Co 3 o 4 、CoO 2 、Co 2 o 3 At least one of the manganese oxides is MnO, Mn 3 o 4 , MnO 2 , Mn 2 o 3 at least one of the During the implementation process, the mass ratio of ball to material used in ball milling is (1~3):1, the speed of ball mill is between 150~250 rpm, and the milling time is 1~4h. The material can be fully mixed evenly, and the particle size of the material after ball milling is 0.5 μm to 3 μm, which is easier to form a new single crystal structure.

[003...

Embodiment 1

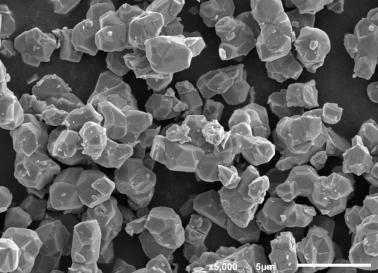

[0035] NiO, Co 2 o 3 , Mn 2 o 3 and Li 2 O was mixed and ball milled in proportion; where the molar ratio of Li:Ni:Co:Mn was 1.08:0.84:0.03:0.13. During the implementation process, the mass ratio of ball to material used in the ball mill was 3:1, the speed of the ball mill was 175rpm, and the ball milling time was 3h. The ball-milled product was sintered in an air atmosphere, specifically, the temperature was raised to 490° C. at a rate of 3° C. / min and then kept for 6 hours. Then sinter in an oxygen atmosphere, specifically, the temperature is raised to 750° C. at a rate of 3° C. / min and then kept for 20 hours. Finally, it was naturally cooled to room temperature to obtain a composition of LiNi 0.84 co 0.03 mn 0.13 o 2 single crystal ternary cathode material.

example 2

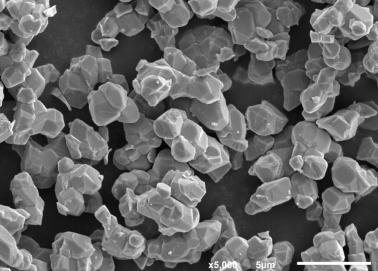

[0037] NiO, Co 3 o 4 , Mn 3 o 4 and Li 2O was mixed and ball milled in proportion; where the molar ratio of Li:Ni:Co:Mn was 1.06:0.90:0.03:0.07. During the implementation process, the mass ratio of ball to material used in the ball mill was 2.5:1, the speed of the ball mill was 210rpm, and the ball milling time was 4h. The ball-milled product was sintered in an oxygen atmosphere, specifically, the temperature was raised to 550° C. at a rate of 3° C. / min and then kept for 5 hours. Then sintering under an oxygen atmosphere, specifically, the temperature was raised to 730° C. at a rate of 3° C. / min and then kept for 20 hours. Finally, it was naturally cooled to room temperature to obtain a composition of LiNi 0.90 co 0.03 mn 0.07 o 2 single crystal ternary cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com