Preparation method of semi-doped and semi-coated NCA positive electrode material

A cathode material and coating technology, applied in the field of NCA cathode material preparation, can solve the problems affecting capacity and cycle life, capacity and cycle decline, electrolyte side reactions, etc., so as to improve the ability to resist electrolyte corrosion and increase capacity and circulation, the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

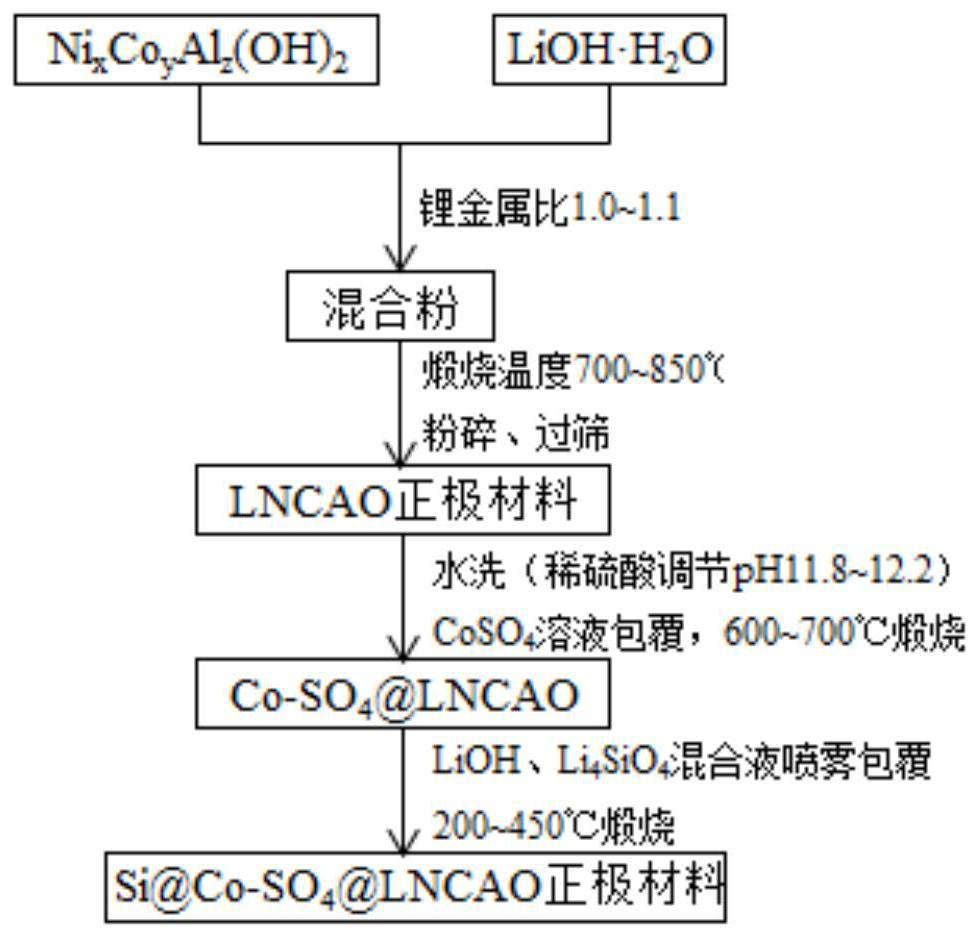

[0022] A preparation method of half-doped and half-coated NCA cathode material, such as figure 1 As shown, the following steps are included, and the following steps are carried out in sequence,

[0023] Step 1, the high nickel precursor Ni x co y al z (OH) 2 or high nickel precursor oxide with LiOH·H 2 O is mixed according to the ratio of lithium metal molar ratio of 1.0 to 1.1, calcined in an oxygen atmosphere of 700 ° C to 850 ° C, crushed and sieved to obtain the general formula Li a Ni x co y al z o 2 The positive electrode material LNCAO, wherein, 1.0<a<1.1, 0.7<x<1, 0.05≤y≤0.15, 0<z≤0.1, and x+y+z=1.0;

[0024] Step 2. Under an inert gas environment, weigh in a beaker to remove CO 2 of ultrapure water, the crystalline CoSO 4 placed in it, stirred and transferred the solution to a separatory funnel to obtain CoSO 4 coating fluid;

[0025] Step 3. Inject inert gas into the stirred tank, add water to the stirred tank, turn on the stirring paddle, put the LNCAO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com