High-temperature-resistant and flame-retardant co-extruded polystyrene foam material and preparation method thereof

A polystyrene foaming and polystyrene technology, which is applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. It is used for problems such as high temperature environment and difficult market promotion, and achieves the effect of low cost, excellent water vapor and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

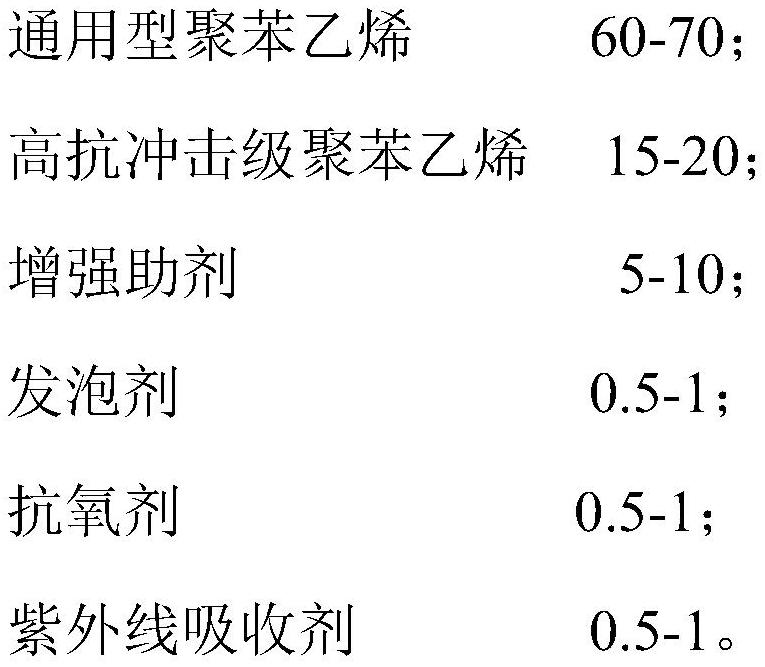

[0028] The composition of the core material in parts by mass of the core material of the high temperature resistant and flame retardant co-extruded polystyrene foam material is as follows:

[0029] General purpose polystyrene (GPPS) 60;

[0030] High Impact Polystyrene (HIPS) 16;

[0031] Enhancement aid 5;

[0032] Foaming agent 0.5;

[0033] Antioxidant 0.5;

[0034] UV absorber 0.5;

[0035] Wherein, foaming agent is sodium carbonate; UV absorber is UVP-327; Antioxidant is antioxidant 1010; Strengthening aid is to adopt rock wool fiber, glass fiber, general-purpose polystyrene according to mass ratio 0.15:0.1: 1 Obtained through high-temperature melt extrusion and granulation by twin-screw extruder.

[0036] The surface layer is divided into A material and B material, wherein A material is a composite of polysulfone resin, high impact polystyrene (HIPS), and high molecular weight brominated epoxy resin modification, and the mass parts of the three are respectively It ...

Embodiment 2

[0044] The raw material mass parts composition of described core material is as follows:

[0045] General purpose polystyrene (GPPS) 70;

[0046] High Impact Polystyrene (HIPS) 19;

[0047] Enhancement aid 8;

[0048] Blowing agent 1;

[0049] Antioxidant 0.9;

[0050] UV absorber 1;

[0051] The surface layer is divided into A material and B material, wherein A material is a composite of polysulfone resin, high impact polystyrene (HIPS), and high molecular weight brominated epoxy resin modification, and the mass parts of the three are respectively It is 79 parts of polysulfone resin; 9 parts of high impact polystyrene (HIPS); 15 parts of high molecular weight brominated epoxy resin modification; consumption is 5% of core material; B material is pure polysulfone resin, The dosage is 8% of material A.

[0052] Other conditions are identical with embodiment 1.

Embodiment 3

[0054] The raw material mass parts composition of described core material is as follows:

[0055] General purpose polystyrene (GPPS) 64;

[0056] High Impact Polystyrene (HIPS) 17;

[0057] Enhancement aid 7;

[0058] Foaming agent 0.8;

[0059] Antioxidant 0.8;

[0060] UV absorber 0.8;

[0061] The surface layer is divided into A material and B material, wherein A material is a composite of polysulfone resin, high impact polystyrene (HIPS), and high molecular weight brominated epoxy resin modification, and the mass parts of the three are respectively It is 75 parts of polysulfone resin; 8 parts of high impact polystyrene (HIPS); 15 parts of high molecular weight brominated epoxy resin modification; consumption is 5% of core material; B material is pure polysulfone resin, The dosage is 10% of material A.

[0062] Other conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com