Wrought aluminum alloy hollow ingot hot top casting crystallizer

A technology of deformed aluminum alloy and hot top casting, which is applied in the field of casting molds and can solve problems such as cracks and inner hole pulling cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

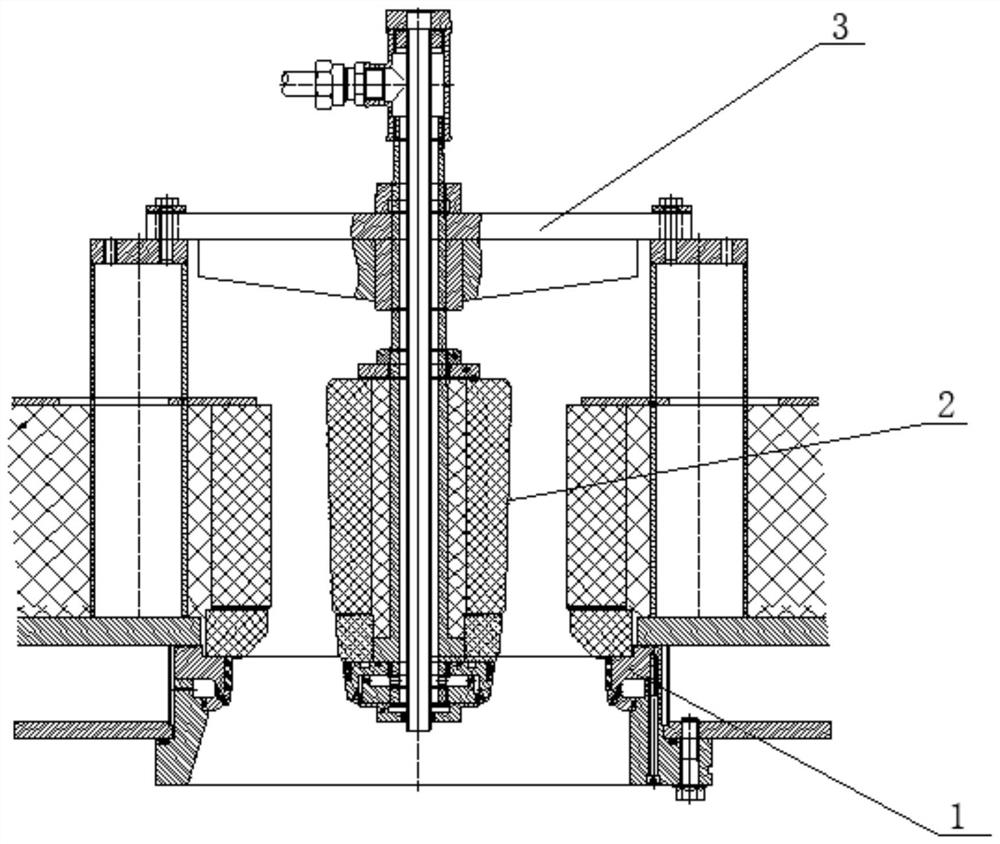

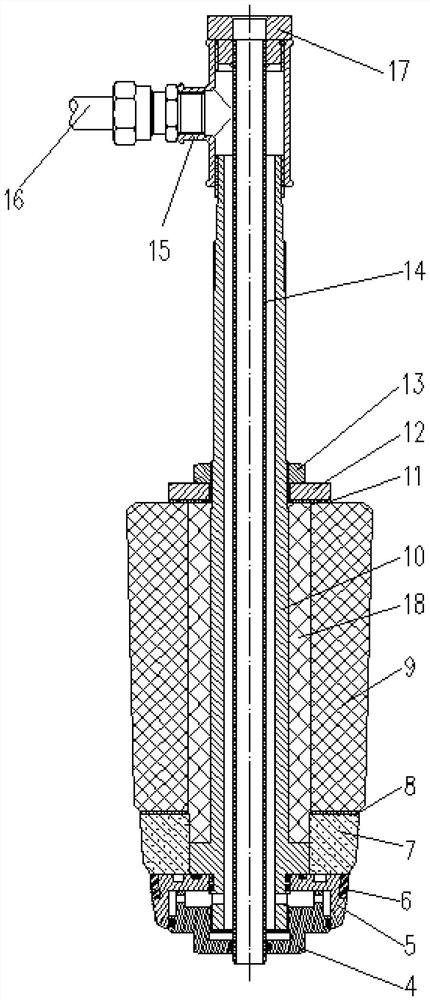

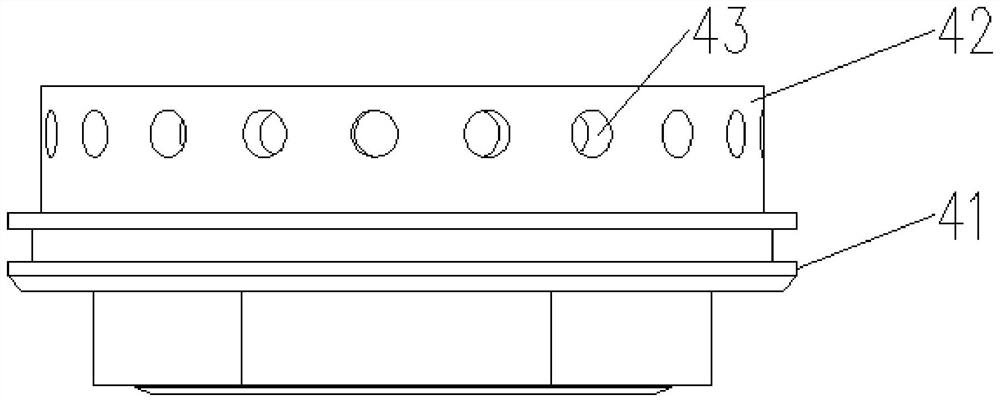

[0022] Specific Embodiment 1: In this embodiment, the deformed aluminum alloy hollow ingot hot top casting crystallizer is composed of an outer crystallizer 1, a crystallizer core 2 and a core bracket 3, and the crystallizer core 2 is fixed on the outer mold through the core bracket 3 Above the liquid inlet of 1, the lower end of the crystallizer core 2 is set in the liquid inlet of the outer crystallizer 1; the crystallizer core 2 is composed of a water-cooled gland 4, a copper crystal ring 5, a graphite ring 6, an adapter plate 7, and a protection Cover 9, adjusting screw rod 10, exhaust pipe 14, positive tee joint 15, metal hose 16 and plugging wire 17; adjusting screw rod 10 is a hollow tube, and both ends of adjusting screw rod 10 are threaded ends, adjusting The bottom of the screw mandrel 10 is provided with an annular boss 103, and the bottom of the annular boss 103 in the adjusting screw mandrel 10 is provided with a first annular groove 105 and a second annular groove...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: a heat insulating pipe 18 is provided between the protective cover 9 and the adjusting screw 10, and the heat insulating pipe 18 is made of refractory fiber paper.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: a first aluminum silicate fiber board 8 is arranged between the adapter plate 7 and the protective cover 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com