Device and method for cyclone separation and reduction of single crystal grains of waste salt

A technology of cyclone separation and cyclone separation, which is applied in the direction of cyclone devices, devices in which the axial direction of the cyclone can be reversed, solid waste removal, etc., and can solve the problems of easily damaged crusher filter screens, crystal salt discharge quality and Efficiency impact, low support strength of the filter screen, etc., to achieve the effect of long service life, simple structure and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

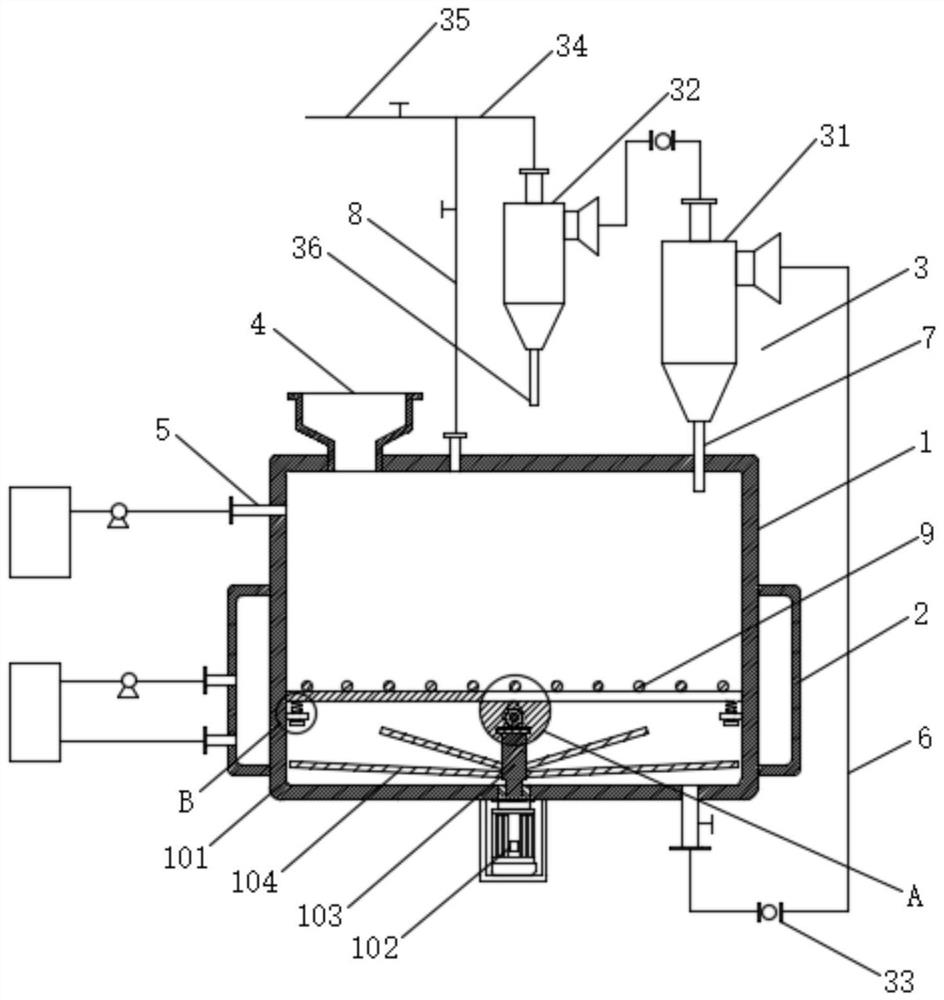

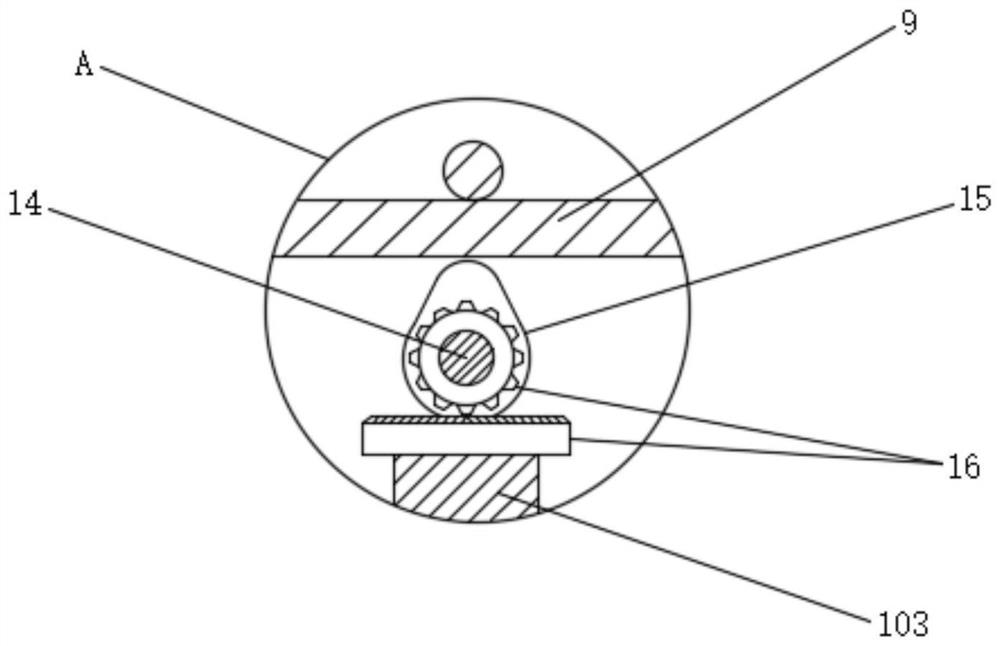

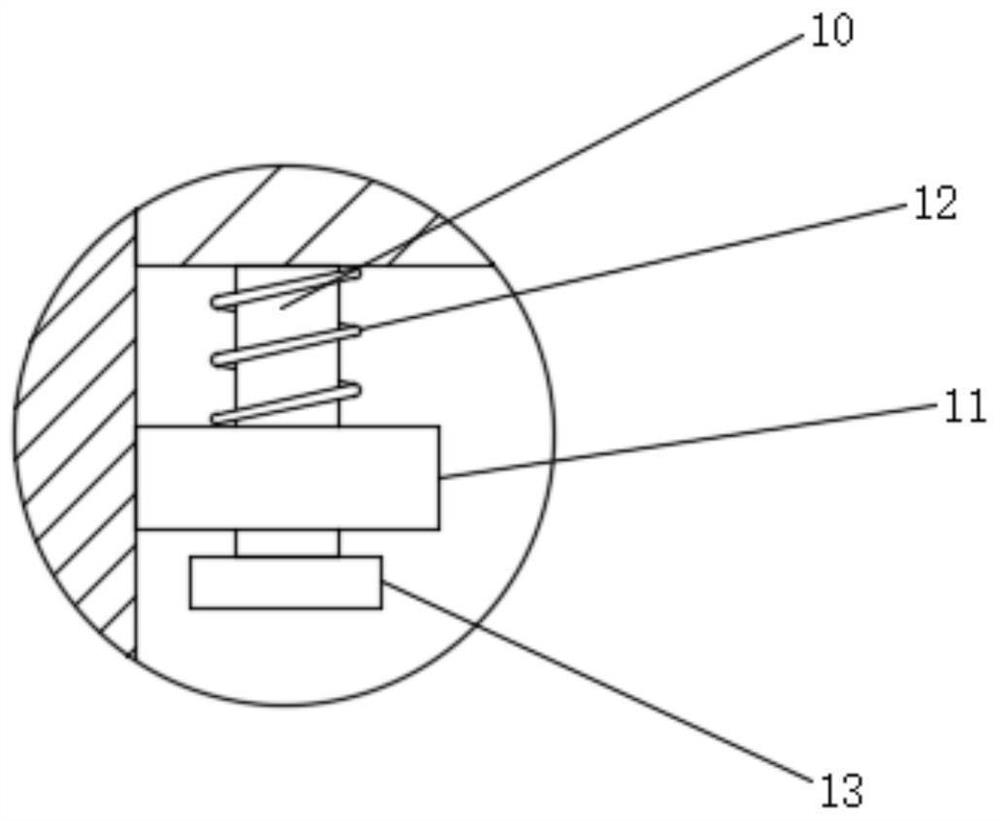

[0030] Such as Figure 1-3 As shown, a device for cyclone separation and reduction of single grains of waste salt includes a crusher 1 and a cyclone separation assembly 3 .

[0031] Crusher 1; it is connected with a salt block feed hopper 4, a saturated brine inlet pipe 5, a mixed material outlet pipe 6, a coarse salt return pipe 7 and a saturated brine return pipe 8, and a heating layer 2 is arranged on the outer wall, and the waste salt block and the The saturated brine input by the saturated brine inlet pipe 5 is mixed and heated and decomposed by the heating layer 2, and then crushed in the crusher 1 to obtain single-crystal salt; the mixture outlet pipe 6 and the saturated brine return pipe 8 Electromagnetic valves are arranged on the outlet pipe 35 and the saturated brine;

[0032] The heating layer 2 is set in the shape of a box, which is connected to an external steam generating device through a circulation pipeline. The steam generating device can use a boiler or dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com