Method for preparing tungsten dispersion strengthened copper composite material through electroforming

A technology for dispersion-strengthening copper and composite materials, applied in electroforming, electrolytic processes, etc., can solve the problems of tungsten dispersion-strengthened copper composite materials without electroforming method, and tungsten dispersion-strengthened copper composite materials without electroplating, and achieve fine particle size. , uniform distribution, uniform and fine distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

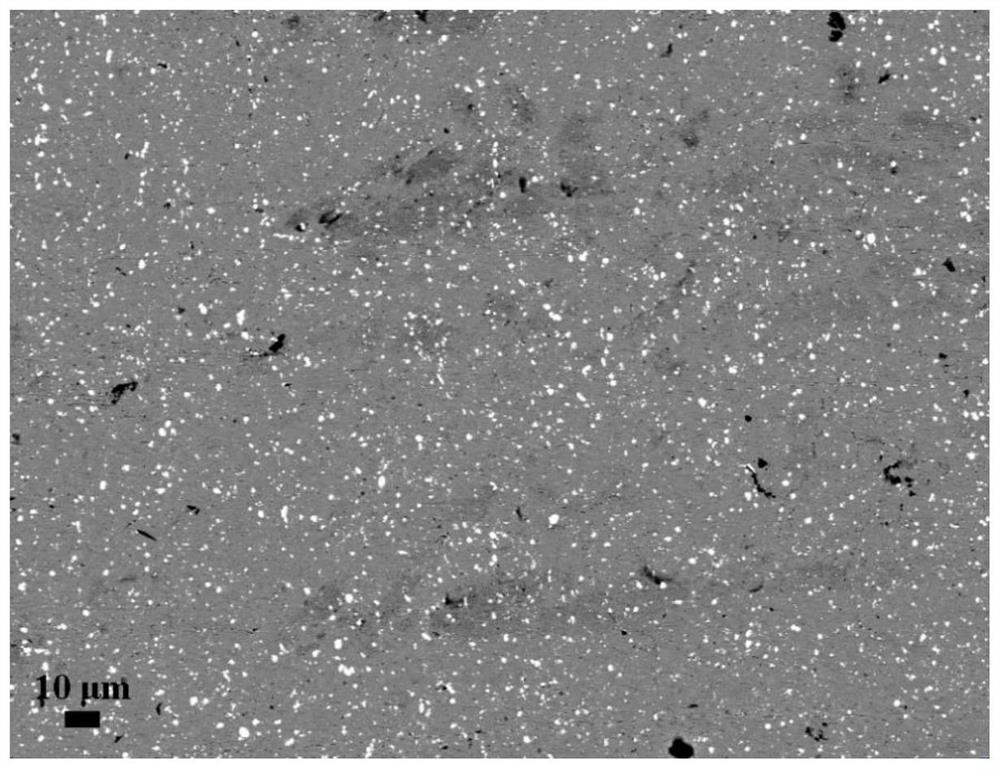

Embodiment 1

[0030] 1. Weigh copper nitrate and sodium tungstate according to the mass ratio of copper to tungsten of 100:1, and add sodium citrate with a content of 1g / L and sodium lauryl sulfate with a content of 0.1g / L. Dissolve in deionized water and stir until completely mixed.

[0031] 2. The cathode copper plate is degreased, pickled and cleaned with deionized water until the surface is clean.

[0032] 3. Add the anode, cathode and the prepared plating solution into the electroplating tank, the DC power supply voltage is 5V, and the cathode current density is controlled to be 1A / dm 2 , the electroforming temperature is 40°C, the pH value is controlled at 8, and the electroforming time is 12h.

[0033] 4. Cleaning and drying after the electroforming is completed, and then demoulding the electroformed components to obtain a tungsten dispersion-strengthened copper composite sheet with a thickness of 0.5 mm.

[0034] In this embodiment, the tensile strength of the tungsten dispersion ...

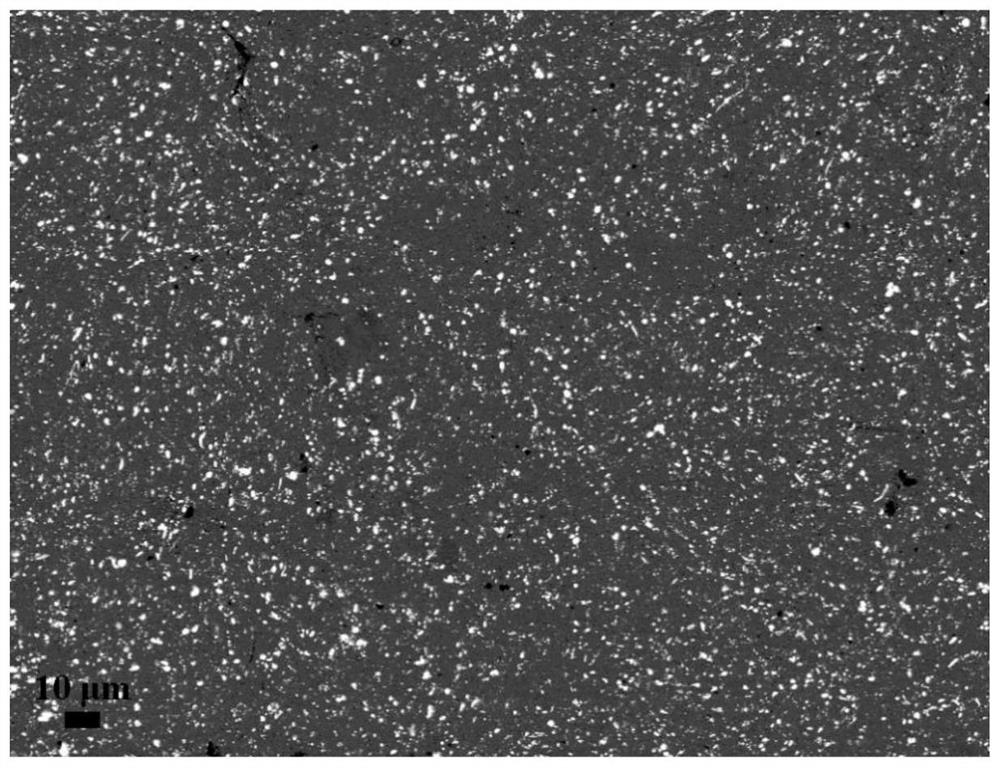

Embodiment 2

[0036] 1. Weigh copper sulfate and ammonium metatungstate according to the mass ratio of copper to tungsten of 10:1, add sodium citrate with a content of 5g / L, and sodium lauryl sulfate with a content of 0.5g / L. Dissolve in deionized water and stir until completely mixed.

[0037] 2. The cathode copper plate is degreased, pickled and cleaned with deionized water until the surface is clean.

[0038] 3. Add the anode, cathode and the prepared plating solution into the electroplating tank, the DC power supply voltage is 8V, and the cathode current density is controlled to be 3A / dm 2 , the electroforming temperature is 70°C, the pH value is controlled at 10, and the electroforming time is 24h.

[0039] 4. Cleaning and drying after the electroforming is completed, and then demoulding the electroformed components to obtain a tungsten dispersion-strengthened copper composite sheet with a thickness of 0.75 mm.

[0040] In this embodiment, the tensile strength of the tungsten dispers...

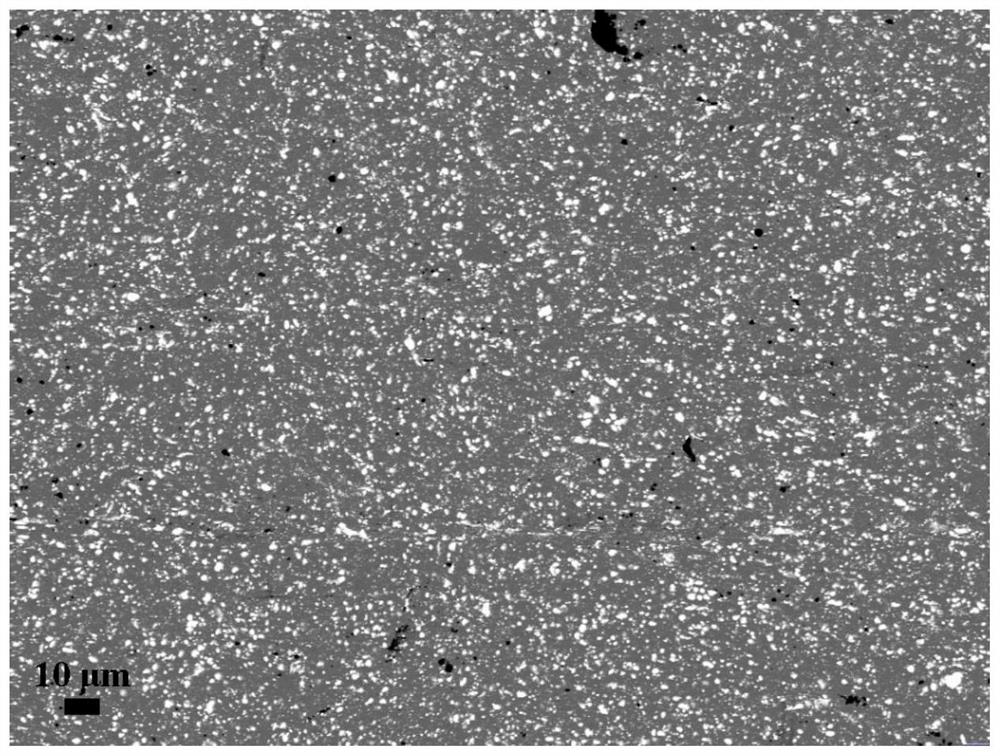

Embodiment 3

[0042] 1. Weigh copper chloride and sodium metatungstate according to the copper:tungsten mass ratio of 5:1, add sodium citrate with a content of 10g / L, and sodium lauryl sulfate with a content of 1g / L. Dissolve in deionized water and stir until completely mixed.

[0043] 2. The cathode copper plate is degreased, pickled and cleaned with deionized water until the surface is clean.

[0044]3. Add the anode, cathode and the prepared plating solution into the electroplating tank, the DC power supply voltage is 10V, and the cathode current density is controlled to be 5A / dm 2 , the electroforming temperature is 80°C, the pH value is controlled at 10, and the electroforming time is 48h.

[0045] 4. Clean and dry after electroforming, and then remove the electroformed components to obtain a tungsten dispersion-strengthened copper composite sheet with a thickness of 1.2 mm.

[0046] In this embodiment, the tensile strength of the tungsten dispersion strengthened copper composite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com