Irradiation cross-linked halogen-free flame-retardant polyolefin material for new energy automobile wire as well as preparation method and application of irradiation cross-linked halogen-free flame-retardant polyolefin material

A new energy vehicle and polyolefin technology, applied in the field of new energy vehicle cables, can solve the problems of difficulty in taking into account water resistance, oil resistance and solvent resistance, large load of new energy vehicles, and difficulty in meeting light weight, etc. Excellent flame retardant effect and delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

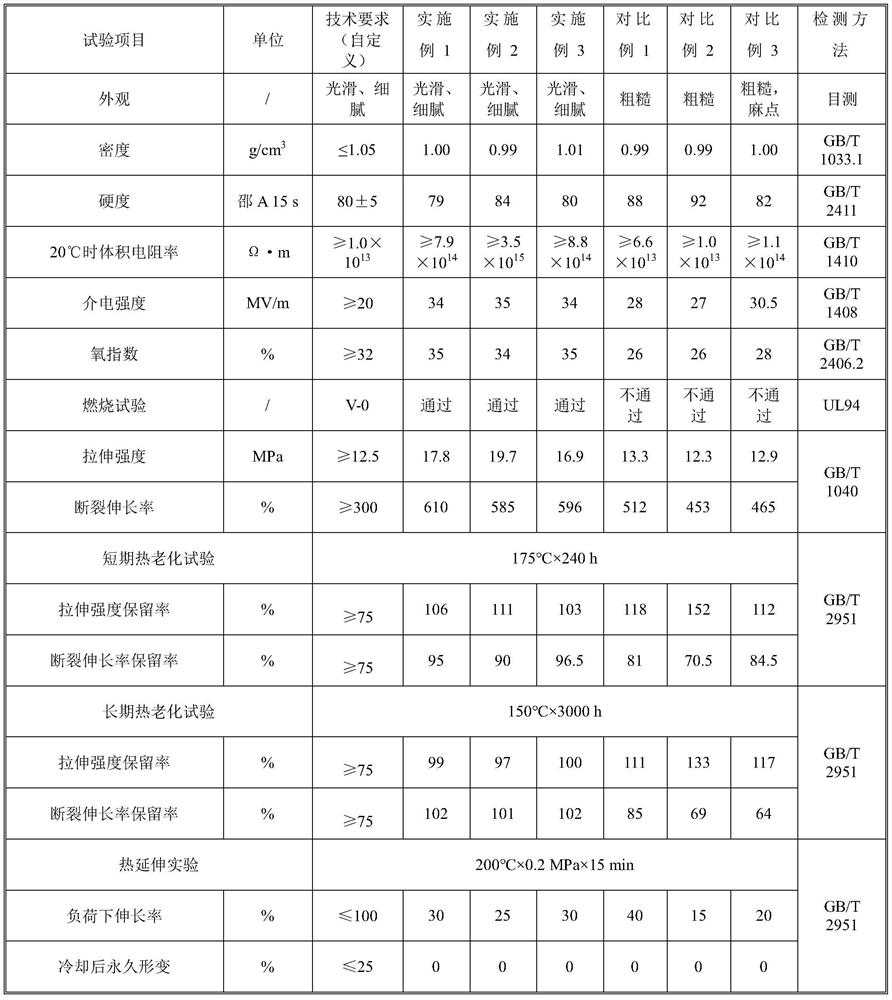

[0041] These examples provide a radiation-crosslinked halogen-free flame-retardant polyolefin material for new energy automobile lines, and its raw material formula is shown in Table 1.

[0042] Table 1

[0043]

[0044]

[0045] The preparation method of the above-mentioned radiation crosslinked halogen-free flame-retardant polyolefin material for new energy automobile lines, the preparation method comprises the following steps:

[0046] (1) Mix all the polyphenylene ether, part of SEBS, part of white oil, part of linear low-density polyethylene resin, and 50% antioxidant in a kneader at low speed, and extrude and granulate on the twin-screw extruder , to make polyphenylene ether masterbatch; the mass ratio of all polyphenylene ether, part of SEBS, part of white oil, and part of linear low-density polyethylene resin is 1:1:1:1, and the extrusion granulation The temperature is:

[0047] Body: 150°C, 200°C, 230°C, 260°C, 260°C, 260°C, 260°C, 260°C, 260°C, 260°C, 250°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com