Crystallization process for producing photoinitiator and product thereof

A photo-initiator and process technology, applied in the field of photo-initiator production, can solve the problems of less temperature control in the cooling process, lack of control of the cooling process, poor storage performance, etc., to solve the problems of low hardness, high hardness and improved storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

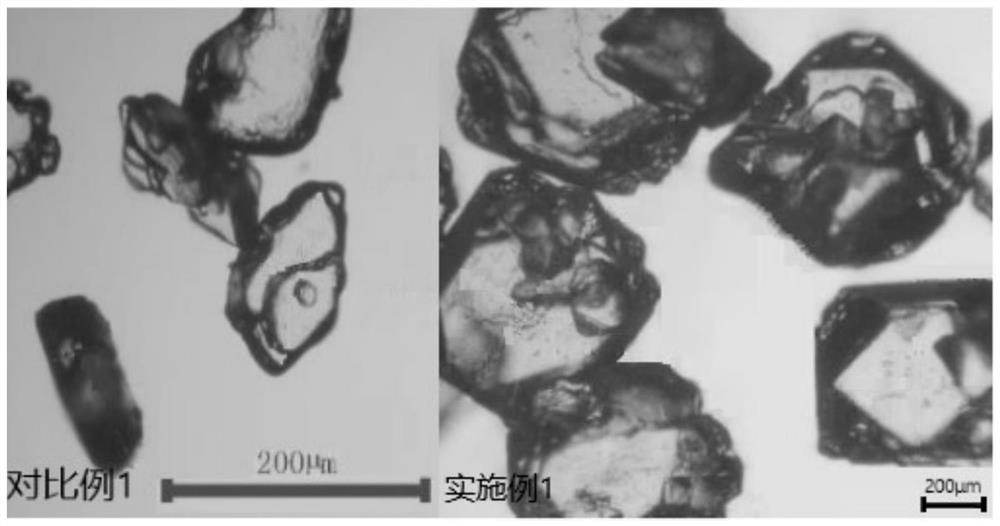

Embodiment 1

[0070] The present embodiment provides a kind of crystallization process that is used for photoinitiator production, specifically comprises:

[0071] (a) Prepare the solution: dissolve the photoinitiator 184 in petroleum ether to obtain a photoinitiator solution with an initial temperature of 50° C. and a concentration of 43.5 wt %;

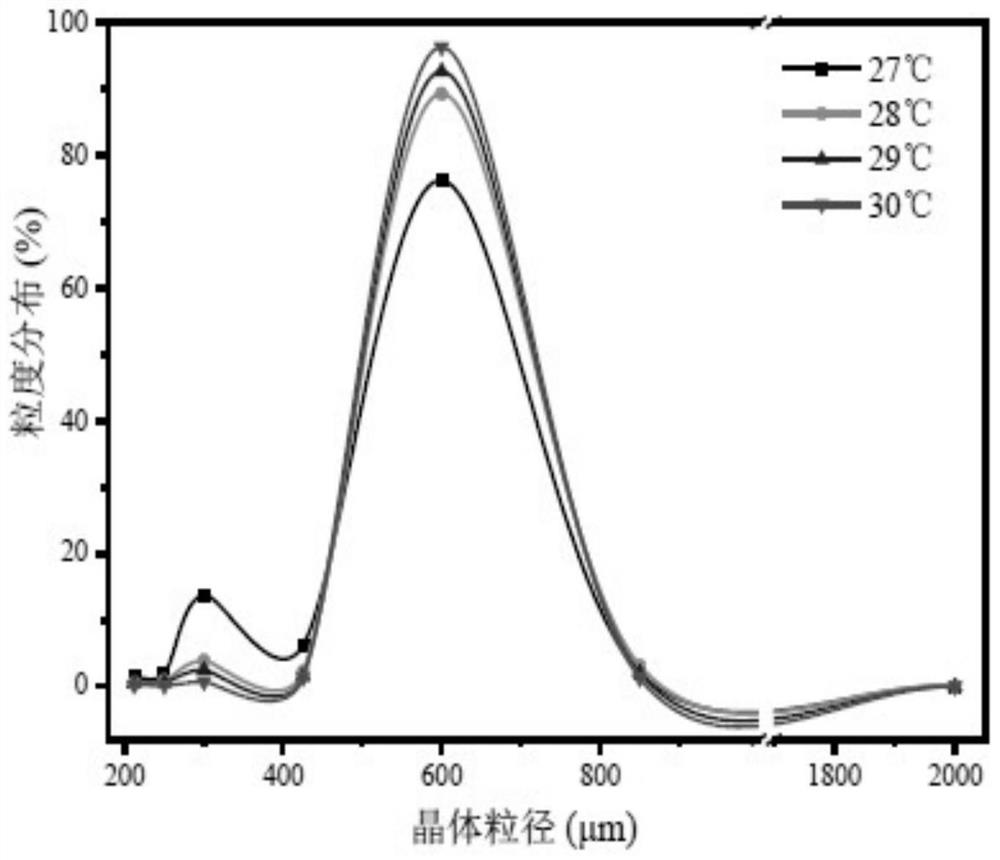

[0072] (b) Pre-cooling: Transfer the photoinitiator solution in step (a) to the cooling crystallization kettle, control the cooling rate of 7°C / h to cool down to 28°C, and the difference between the preset temperature value and the crystallization temperature is 1°C;

[0073] (c) Adding seed crystals: adding a particle diameter of 60 mesh to 70 mesh seed crystals to the precooled solution in step (b), the added quality of the seed crystals is the same as that of the photoinitiator in the photoinitiator solution. The mass ratio is 1.6%;

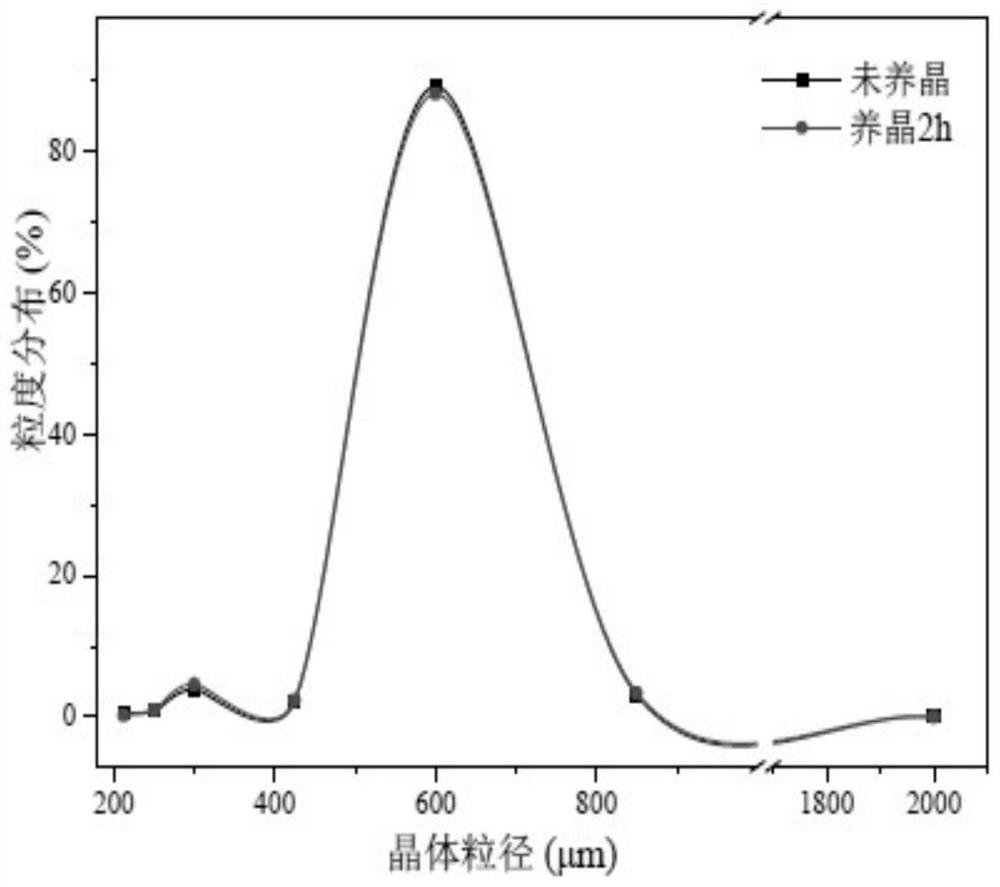

[0074] (d) crystallization by cooling at a uniform rate: in the control step (c), the solution is cooled to ...

Embodiment 2

[0078] The only difference between the crystallization process in this example and Example 1 is that the seed crystal addition temperature is replaced by 29° C., and other parameters and conditions are exactly the same as in Example 1.

Embodiment 3

[0080] The only difference between the crystallization process in this example and Example 1 is that the seed crystal addition temperature is replaced by 30° C., and other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com