Pasteurization treatment method for feces

A manure and treatment tank technology, applied in the fields of sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of not being completely harmless, long period of manure treatment, destroying the ecological environment, etc. , to achieve the effect of delaying the cleaning cycle, shortening the processing cycle, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

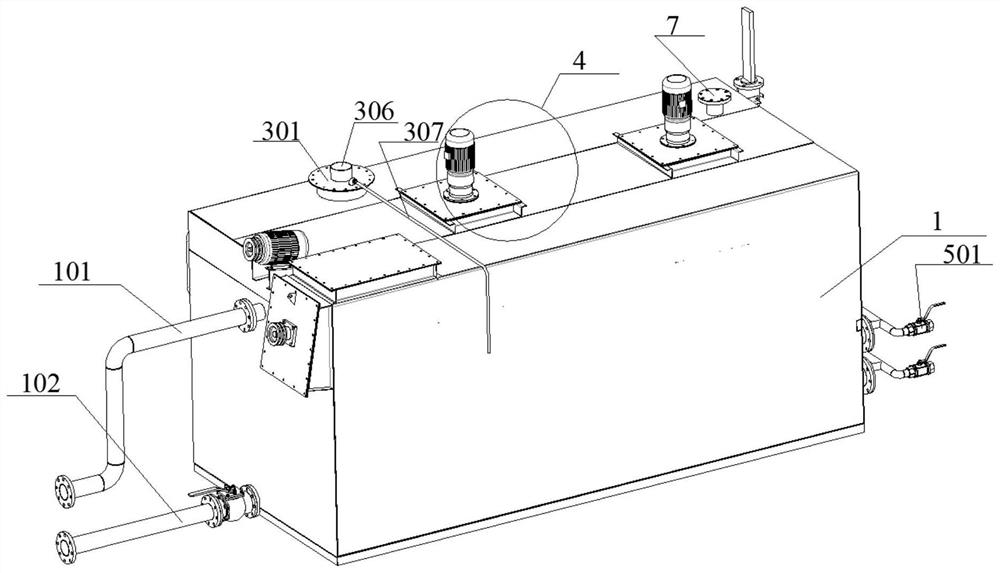

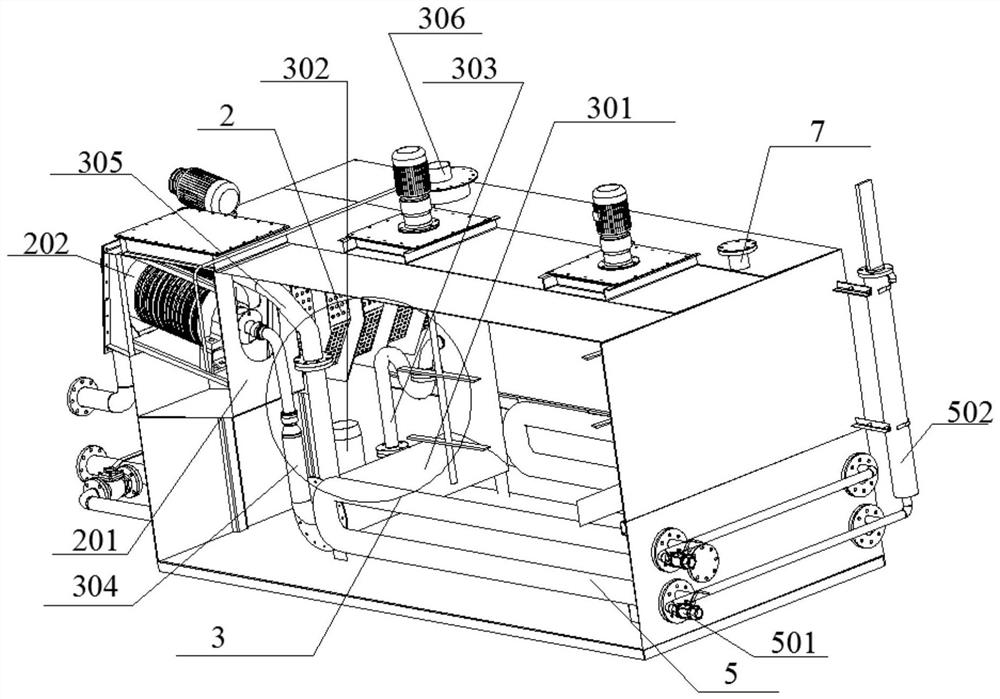

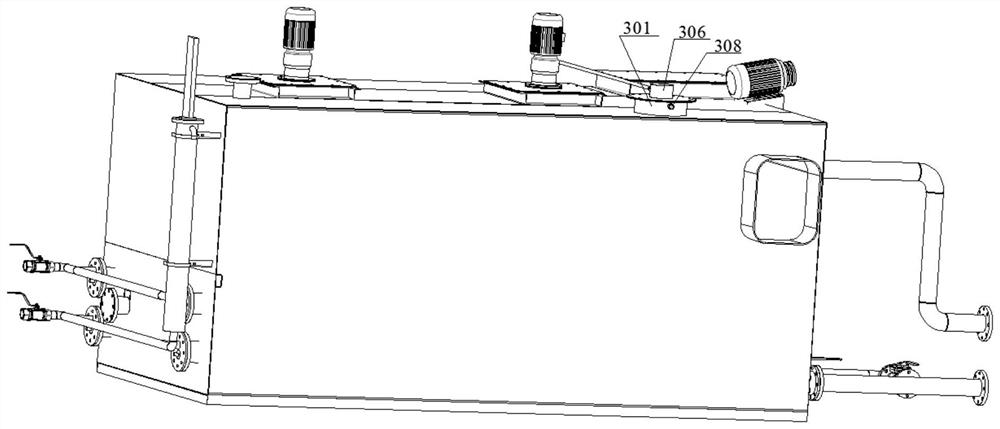

[0026] like Figure 1-4 As shown, the present invention provides a manure treatment tank, including a tank body 1, the tank body 1 is hollow, the tank body 1 is welded by profiles, and the joints of the tank body 1 are made of Fully welded to ensure the overall tightness of the tank body 1, the left side of the tank body 1 is provided with a feed pipe 101 and a discharge pipe 102 that are fixedly connected, and through the setting of the feed pipe 101 and the discharge pipe 102, for For manure filling and discharge of finished fermentation products, the discharge pipe 102 is arranged below the feed pipe 101, and a sieve plate 2 is installed in the tank body 1, and multiple groups of filter plates are evenly arranged on the sieve plate 2. hole, the sieve plate 2 is arranged in multiple groups in the tank body 1, and is used to isolate the plastic bag large particle waste residue in the feces. The inner wall of the partition forms an isolation cabin, and the left side of the pa...

Embodiment 2

[0033] like Figure 1-4 As shown, the stirring device 4 includes a driving motor 401, the driving motor 401 is fixedly connected to the tank body 1 through fasteners, the driving motor 401 is fixedly connected to the stirring paddle 402, and the stirring paddle 402 is connected through the shaft coupling The device is fixedly connected to the motor, the operation of the motor is controlled by the embedded control host, the motor is provided with a current sensor, the current sensor is connected to the embedded control host through a cable, and the embedded control host is fixedly connected to the On the inner wall of the tank body 1 , the abutment between the drive motor 401 and the tank body 1 is sealed and connected to ensure that the stirring device 4 does not have gas leakage during actual operation.

[0034] In this embodiment, through the setting of the stirring device 4, the manure in the tank body 1 can be kept uniform up and down, ensuring the quality of the fermentat...

Embodiment 3

[0036] like Figure 1-4 As shown, a heat exchanger 5 is installed under the stirring device 4 for heating and cooling the inside of the tank body 1. The cross section of the heat exchanger 5 is U-shaped, and the heat exchanger 5 is symmetrically arranged. At the bottom of the pipe body, it is convenient to uniformly heat the feces inside the tank body 1, and shorten the heating time and cooling time of the feces. The heat exchanger 5 is made of heat-conducting materials, and the right side of the heat exchanger 5 A cut-off valve 501 is installed to connect to the external heat storage tank. A liquid level monitoring tube 502 is also installed on the tank body 1, and the liquid level monitoring tube 502 is connected to the heat exchanger 5. , used to detect the water level in the heat exchanger 5 to ensure the safe production and use of the heat exchanger 5. The heat exchanger 5 is filled with water, and the integrated sensor 6 is rotatably connected to the inner wall of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com