Preparation method of nickel-aluminum coated nickel-iron-manganese sodium ion precursor material

A precursor, sodium ion technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problem of unstable internal structure of sodium ion battery materials, achieve high stability and safety, improve energy, improve The effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1, the nickel sulfate solution, the ferrous sulfate solution and the manganese sulfate solution are configured according to the molar ratio of 0.25:0.5:0.25 as the nickel-iron-manganese metal salt A solution with a concentration of 2mol / L, and the ammonia water complexation of 1mol / L is configured agent solution and 1mol / L sodium hydroxide solution.

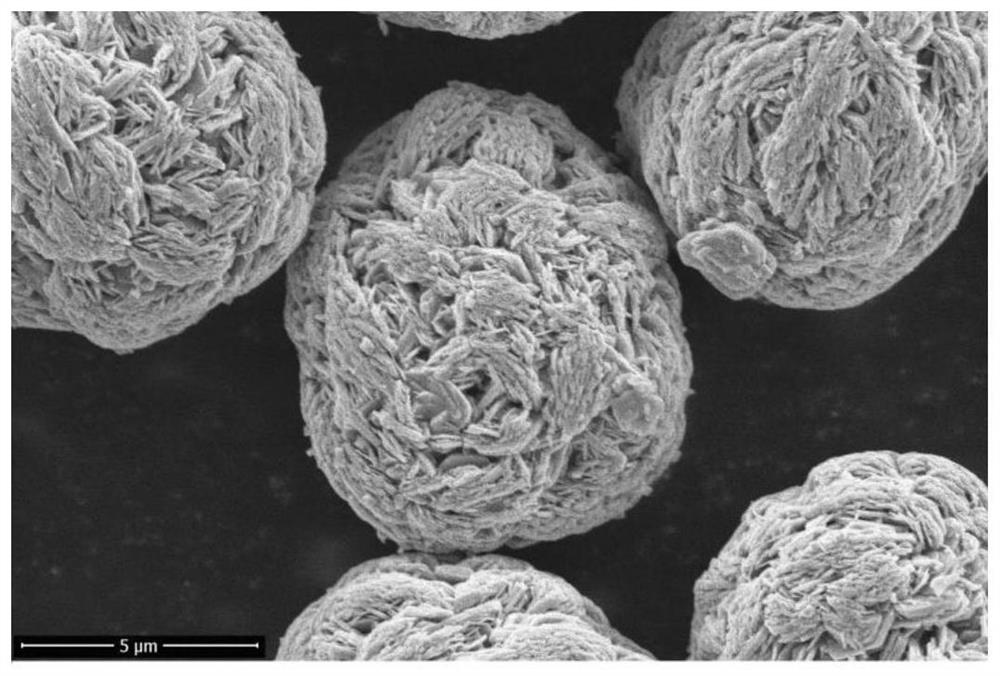

[0022] Step 2. Add solution A, ammonia water complexing agent and sodium hydroxide solution into a 1000L reaction kettle at a certain feed rate, react at 40°C for 50h, control the reaction pH of the system to 9.5-10, and the ammonia concentration to 3 -5g / L. A precursor with good sphericity, uniform primary particles and dense packing is obtained: Ni 0.25 Fe 0.5 mn 0.25 (OH) 2 , the average particle size of the precursor is 3 μm. The flow of the solution A is 30L / h, the flow of ammonia water is 3L / h, the flow of the sodium hydroxide solution is 8L / h, and the stirring speed is 280-350r / min.

[0023] Step 3, the p...

Embodiment 2

[0028] Step 1, the nickel sulfate solution, the ferrous sulfate solution and the manganese sulfate solution are configured according to the molar ratio of 0.34:0.33:0.33 as the nickel-iron-manganese metal salt A solution with a concentration of 2mol / L, and the ammonia water complexation of 2mol / L agent solution and 2mol / L sodium carbonate solution.

[0029] Step 2. Add solution A, ammonia complexing agent and sodium carbonate solution into a 1000L reactor at a certain feed rate, react at 50°C for 60h, control the reaction pH of the system to 9-9.5, and the ammonia concentration to 4- 6g / L. A precursor with good sphericity, coarse primary particles and dense packing is obtained: Ni 0.34 Fe 0.33 mn 0.33 (OH) 2 , the average particle size of the precursor is 5 μm. The flow rate of the solution A is 40L / h, the flow rate of ammonia water is 4L / h, the flow rate of liquid caustic soda is 10L / h, and the stirring speed is 260-320r / min.

[0030]Step 3, the preparation concentratio...

Embodiment 3

[0033] Step 1, nickel sulfate solution, ferrous sulfate solution and manganese sulfate solution are configured according to the ratio of molar ratio of 0.6:0.2:0.2 to be the nickel-iron-manganese metal salt A solution with a concentration of 3mol / L, and configure 3mol / L ammonia water complexation agent solution and 3mol / L potassium hydroxide solution.

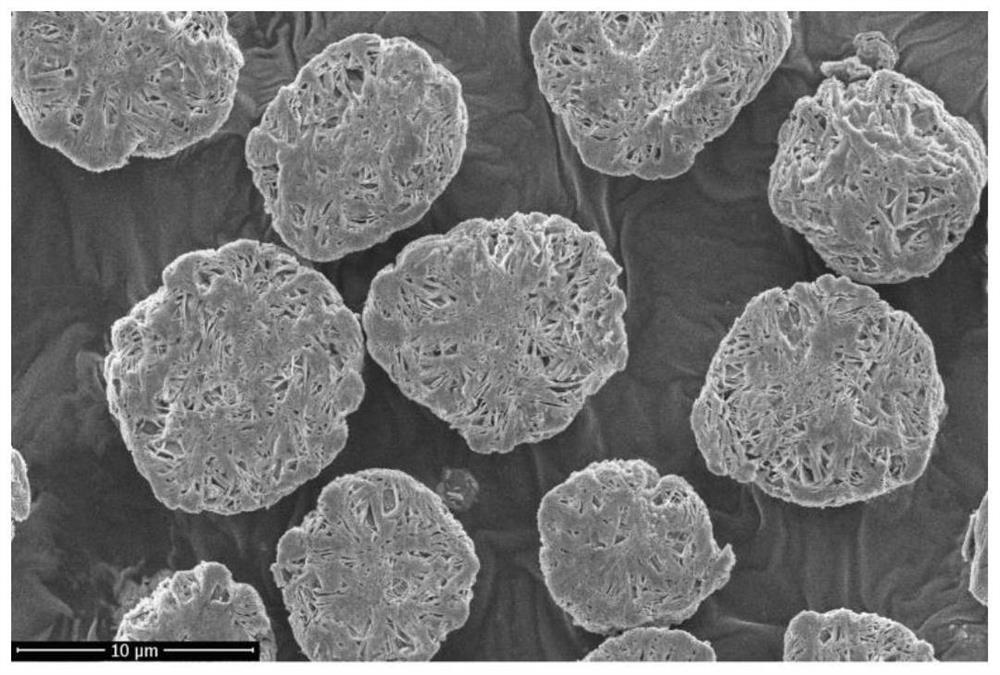

[0034] Step 2. Add solution A, ammonia water complexing agent and potassium hydroxide solution into a 1000L reaction kettle at a certain feed rate, react at 70°C for 80h, control the reaction pH of the system to 9.8-10, and the ammonia concentration to 6 -8g / L. A precursor with better sphericity, more uniform primary particles and dense packing is obtained: Ni 0.6 Fe 0.2 mn 0.2 (OH) 2 , the average particle size of the precursor is 10 μm. The flow rate of the solution A is 50L / h, the flow rate of the ammonia water is 6L / h, the flow rate of the potassium hydroxide solution is 15L / h, and the stirring speed is 230-250r / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com