Preparation method of efficient acid-resistant mordenite molecular sieve

A mordenite and acid-resistant technology, applied in the field of inorganic molecular sieve technology synthesis, can solve the problems of long synthesis time, low efficiency, unknown long-term strong acid resistance, environmental pollution, etc. The effect of uniform distribution of aluminum elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]The ratio of the synthetic solution is 8Na 2 O:36SiO 2 :1.4Al 2 o 3 :1600H 2 O:8.2NaF. The specific operation is: divide the deionized water into three parts, add sodium hydroxide to one part of deionized water to dissolve, add silica sol to the sodium hydroxide solution to form a silicon source precursor solution; add sodium metaaluminate to another part Dissolve in a portion of water to form an aluminum source precursor solution; add the aluminum source precursor solution drop by drop to the silicon source precursor solution under stirring, and stir at room temperature for 1 hour; dissolve sodium fluoride in the last portion of deionized water, and add it to the aforementioned The solution was stirred at room temperature for 1h. Then add the seed crystal and control the mass concentration of the seed crystal to 0.7wt%, transfer it to the reaction kettle after stirring for 30min, and synthesize at 180°C for 12h, and the crystallized product is centrifuged repeatedl...

Embodiment 2

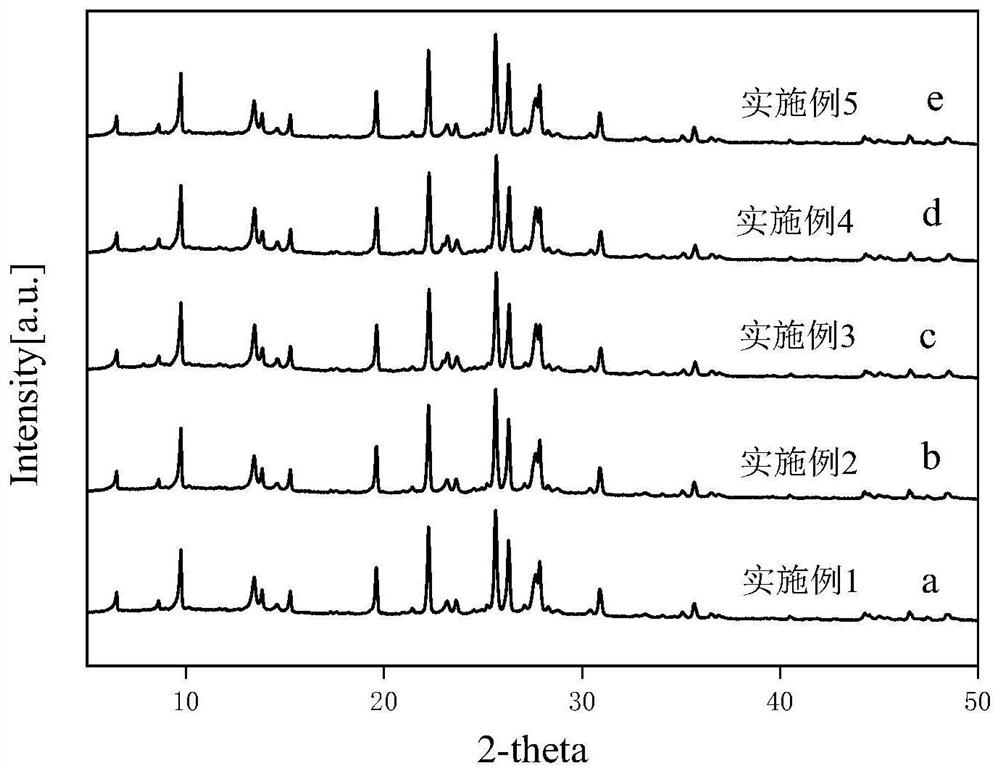

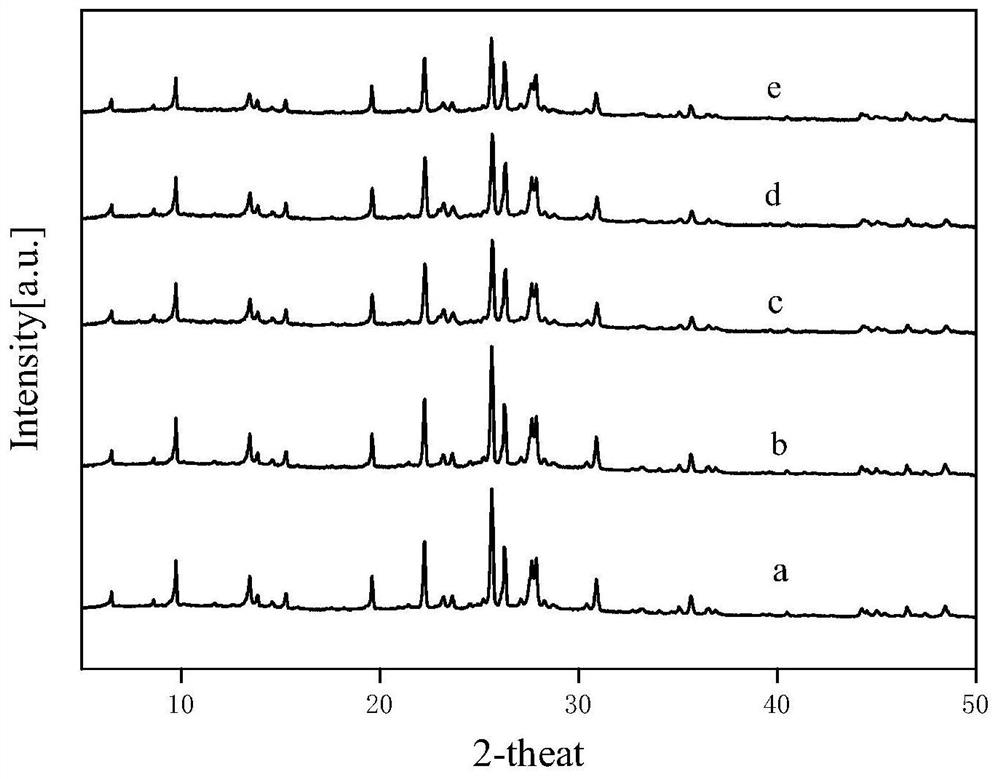

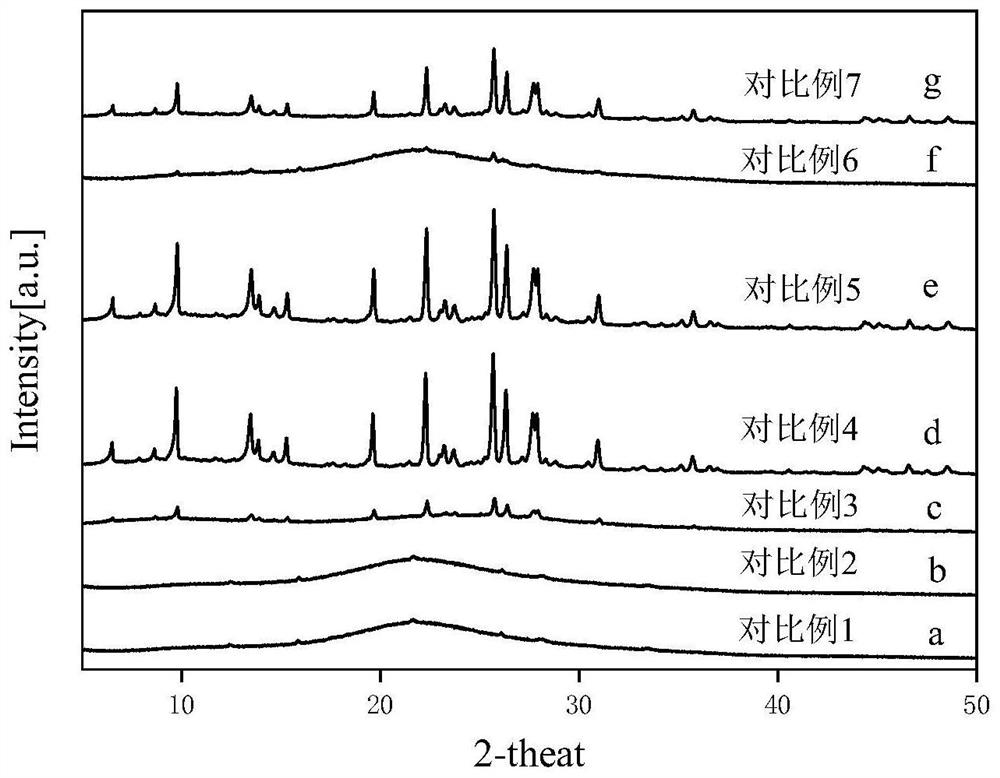

[0039] Synthetic proportioning is constant, and the hydrothermal synthesis time is changed into 18h, and all the other synthetic conditions are identical with embodiment 1, and solid product is pure mordenite through XRD analysis ( figure 1 b), SEM characterization results are micron-scale grains, the shape is flat, and the grain size is about 2-3 microns ( Figure 5 c), analyzed by EDS ( Figure 10 ), the distribution of Al elements is uniform. Gained mordenite is acid-treated, and the treatment conditions are exactly the same as Example 1, and the acid-treated product is characterized by XRD ( figure 2 b) with no acid treatment ( figure 1 b) In comparison, the crystallization strength has only decreased by 4%, and the SEM characterization results show that the surface morphology remains good ( Figure 5 d).

Embodiment 3

[0041] Change the ratio of synthetic liquid to 9.5Na 2 O:39SiO 2 :1.7Al 2 o 3 :1700H 2 0:14NaF, all the other synthesis conditions are identical with embodiment 1, and solid product is pure mordenite ( figure 1 c), SEM characterization results are micron-scale grains, the shape is oval, and the grain size is about 2-3 microns ( Figure 5 e), analyzed by EDS ( Figure 11 ), the distribution of Al elements is uniform. Gained mordenite is acid-treated, and the treatment conditions are exactly the same as Example 1, and the acid-treated product is characterized by XRD ( figure 2 c) with no acid treatment ( figure 1 c) In comparison, the crystallization strength has only decreased by 4%, and the SEM characterization results show that the surface morphology remains good ( Figure 5 f).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com