Florfenicol soluble powder and preparation method thereof

A florfenicol and soluble technology, which is applied in the field of florfenicol soluble powder and its preparation, can solve the problems of inability to maximize the solubility of florfenicol, insufficient contact of particles of raw and auxiliary materials, and discounted inclusion effect. To achieve the effect of improving bioavailability, improving inclusion effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A florfenicol soluble powder, the composition of every 100g product is: florfenicol 20g, beta cyclodextrin 74.3g, poloxamer F68 0.5g, glycerin formal 3g, glycerol triacetate 2g, ten Dialkyl sodium sulfate 0.2g.

[0035] The method for preparing above-mentioned Florfenicol soluble powder, its steps are as follows:

[0036] S1. Accurately weigh 20 g of florfenicol, 74.3 g of beta-cyclodextrin, 0.5 g of poloxamer F68, 3 g of glycerol formal, 2 g of glycerol triacetate, and 0.2 g of sodium lauryl sulfate, and set aside;

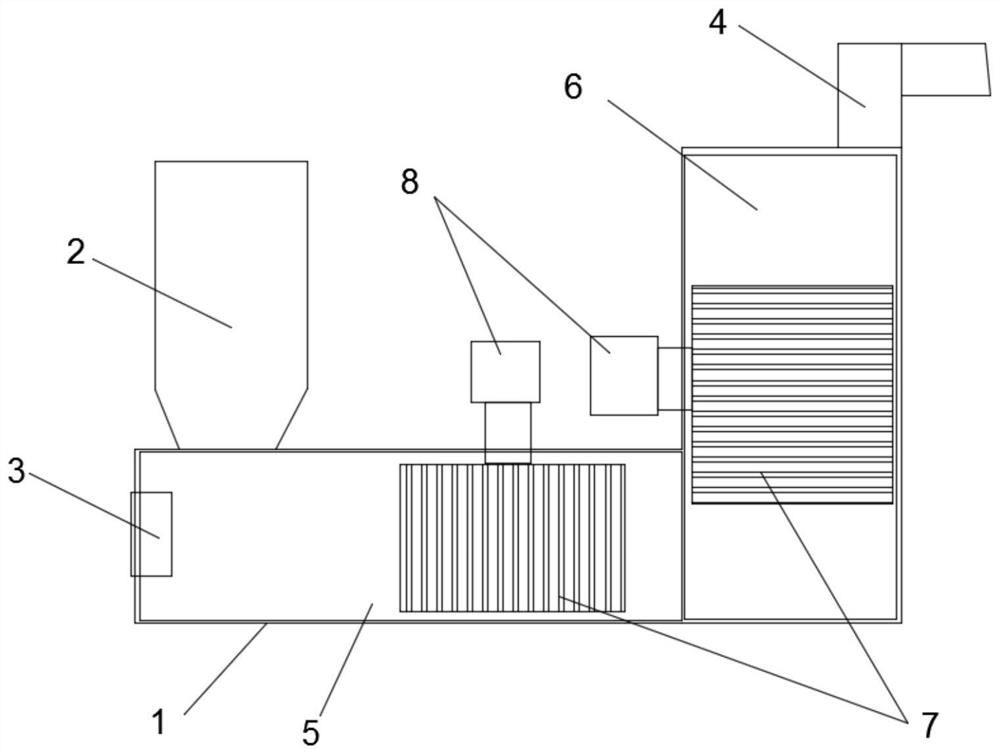

[0037] S2, first mix florfenicol and beta-cyclodextrin evenly, then pulverize in the airflow mill, the airflow mill includes a body 1, a hopper 2, and a high-pressure airflow input port 3, and the high-pressure airflow input port is provided with 3 settings On one side of the body 1, the other side of the body 1 is also provided with a discharge port 4, the hopper 2 is fixedly installed on the top of the side of the body 1 provided with the high-pressure ...

Embodiment 2

[0041] A florfenicol soluble powder, the composition of every 100g product is: florfenicol 20g, beta-cyclodextrin 73.7g, poloxamer F127 1.0g, glycerin formal 3.5g, triton X-100 1.5g, sodium lauryl sulfate 0.3g.

[0042]The method for preparing above-mentioned Florfenicol soluble powder, its steps are as follows:

[0043] S1. Accurately weigh 20g of florfenicol, 73.7g of beta-cyclodextrin, 1.0g of poloxamer F127, 3.5g of glycerin formal, 1.5g of triton X-100, 0.3g of sodium lauryl sulfate ,spare;

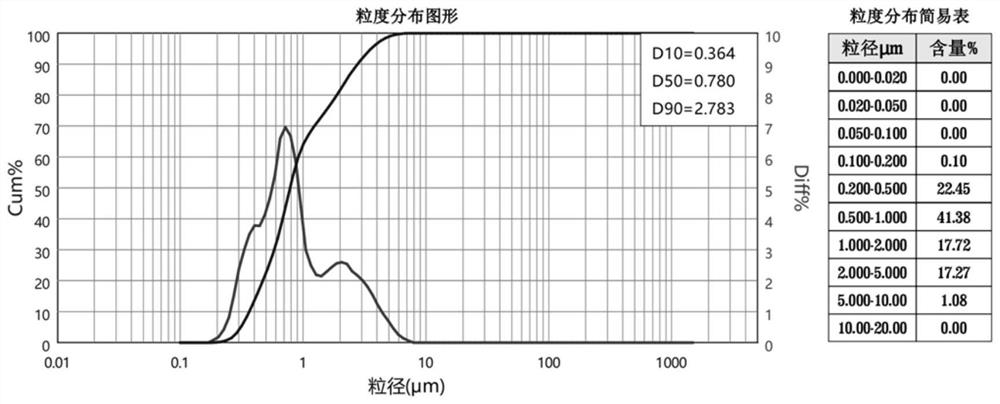

[0044] S2. First mix florfenicol and beta-cyclodextrin evenly, then pulverize in a jet mill, the air pressure is 1.3Mpa, the particle size of the detected particle is in the range of D90=5μm, and the solubility of the micropowder is 1200ppm or above;

[0045] S3. Stir Triton X-100 and glycerin formal in hot water at 40-45°C to dissolve and clarify, put into the ultrafine pulverized clathrate obtained in S2, stir to dissolve and clarify, and then add Poloxamer F127 and Sodium laury...

Embodiment 3

[0048] A florfenicol soluble powder, the composition of every 100g product is: florfenicol 20g, beta cyclodextrin 74.7g, xylooligosaccharide 0.7g, xanthan gum 0.3g, triton X-100 0.5 g, 3.5 g of triacetin, 0.1 g of sodium dodecylbenzenesulfonate, and 0.2 g of sodium xylenesulfonate. When xylooligosaccharide and xanthan gum are used at a ratio of 7:3, the suspension of the product can be better improved, and it can help to achieve a higher degree of dispersion when dissolved in water.

[0049] The method for preparing above-mentioned Florfenicol soluble powder, its steps are as follows:

[0050] S1. Accurately weigh 20g of florfenicol, 74.7g of beta-cyclodextrin, 1.0g of poloxamer F127, 0.5g of triton X-1000, 3.5g of triacetin, sodium dodecylbenzenesulfonate 0.1g, sodium xylene sulfonate 0.2g, for subsequent use;

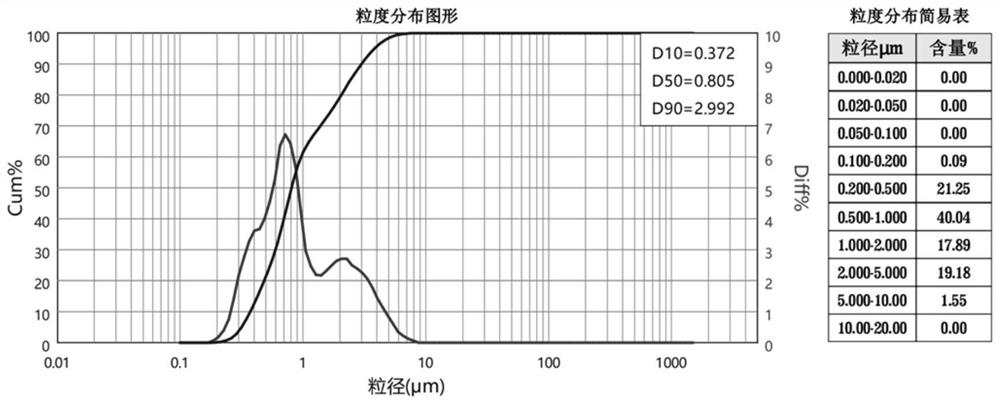

[0051] S2. First mix florfenicol and beta-cyclodextrin evenly, then pulverize in a jet mill, the air pressure is 1.3Mpa, the particle size of the detected particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com