Built-in load sensor of high-pressure vessel and load calculation method

A technology of load sensor and high-pressure container, applied in the field of sensors, can solve the problems of friction deduction, affecting measurement accuracy, and inability to obtain load value accurately, and achieve the effect of stable electrolytic properties, high sensitivity, and stable observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings.

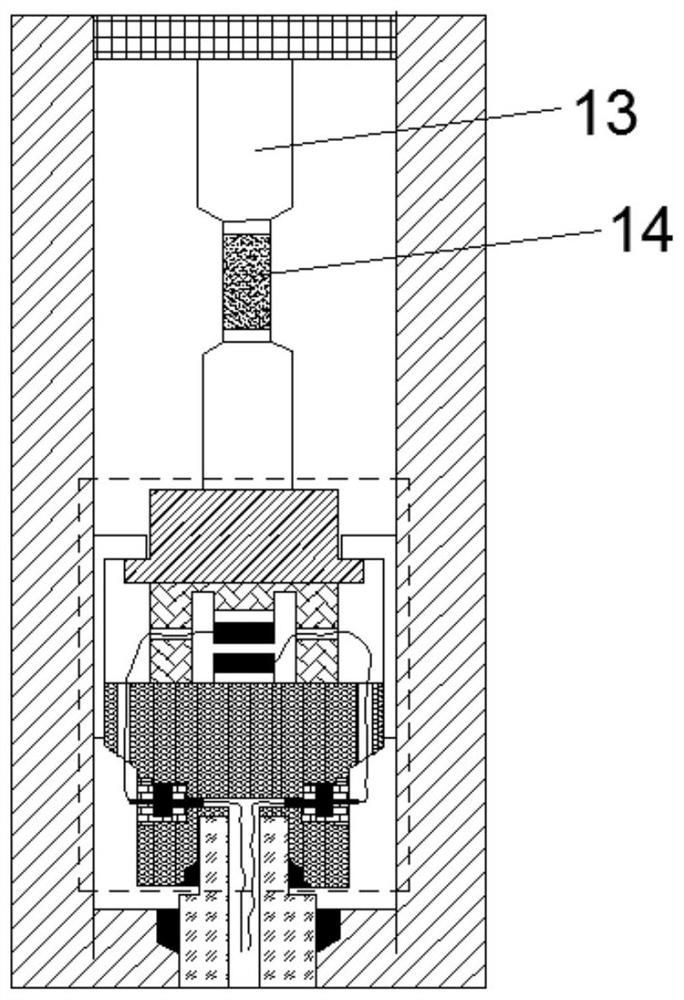

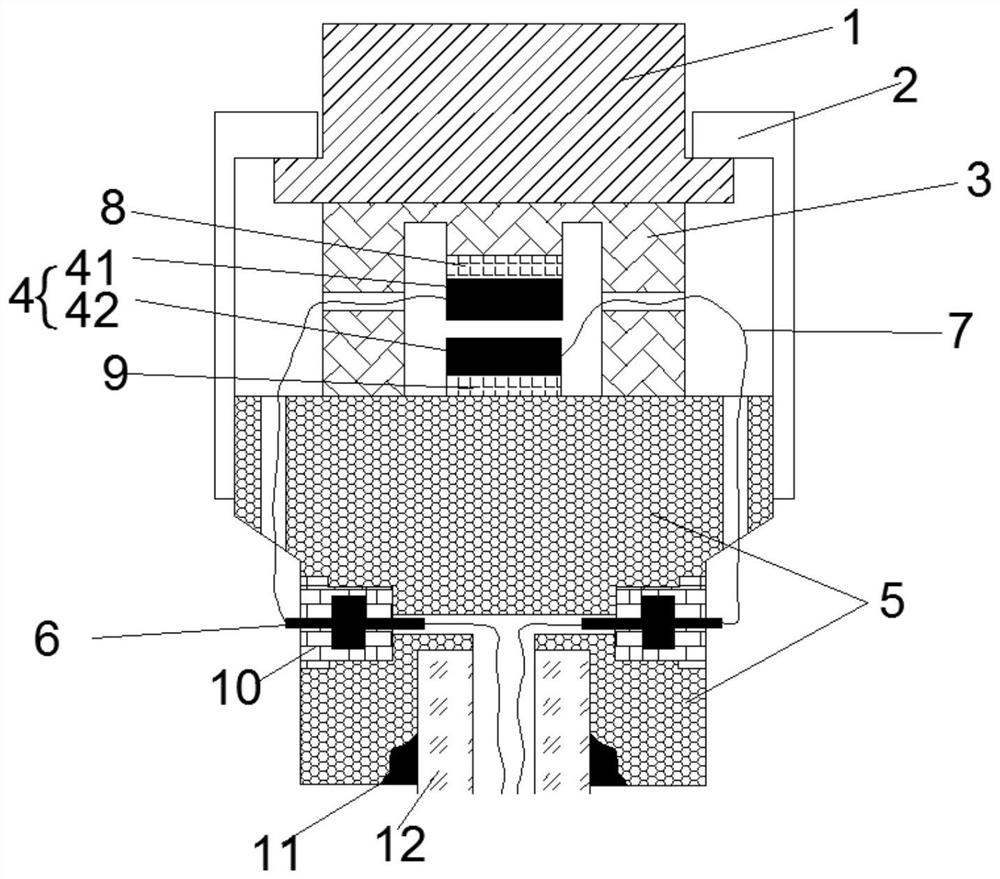

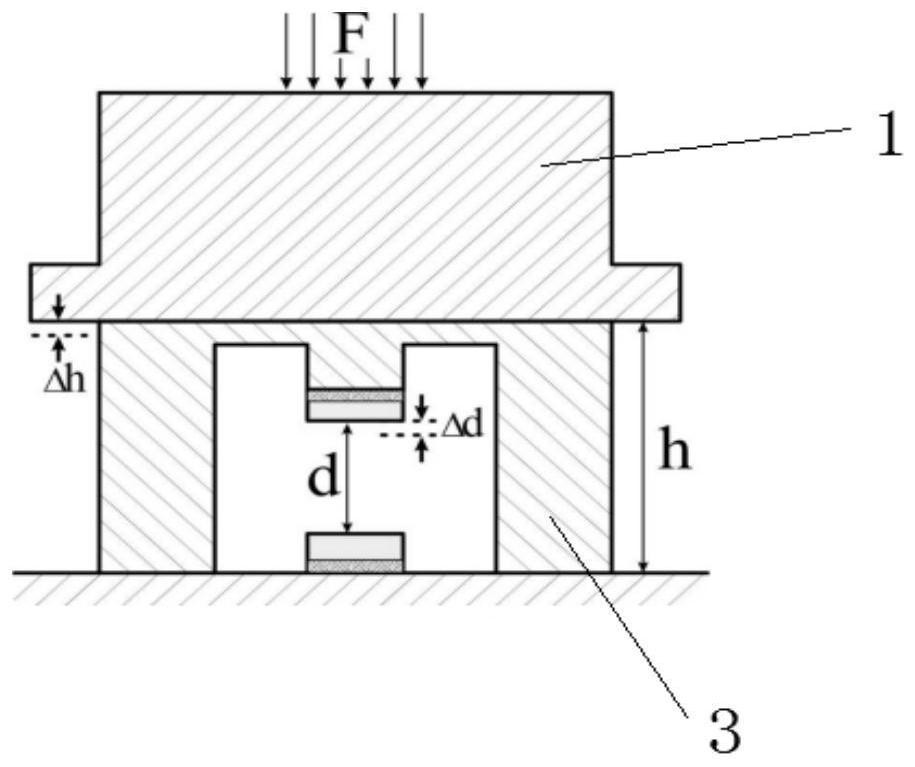

[0028] refer to Figure 1-3 , as a first aspect of the present invention, a built-in load sensor in a high-pressure vessel is provided, the load sensor is built in a high-pressure vessel with a pressure of 300 MPa, the load sensor and the high-pressure vessel are both cylindrical, and the load sensor is closely connected with the high-pressure vessel, and the high-pressure It is realized by the argon atmosphere pressurized by the supercharger, and the inside of the sensor is also filled with high-pressure argon gas. The experimental sample 14 is placed in the ceramic pressure rod 13, and the experimental sample 14 is loaded by the ceramic pressure rod 13 and the axial pressure piston 12. Then connect the measuring meter externally through the wire 7 of the sensor, and measure the data in real time through the measuring meter.

[0029] The struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com