Easily degradable coated yarn and preparation method thereof

A kind of coated yarn, easy to degrade technology, applied in rayon manufacturing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve the problem that PVC plastic is difficult to degrade, cannot meet environmental protection needs, and has large environmental pollution, etc. problems, achieve good deformation resistance, excellent thermal radiation effect, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

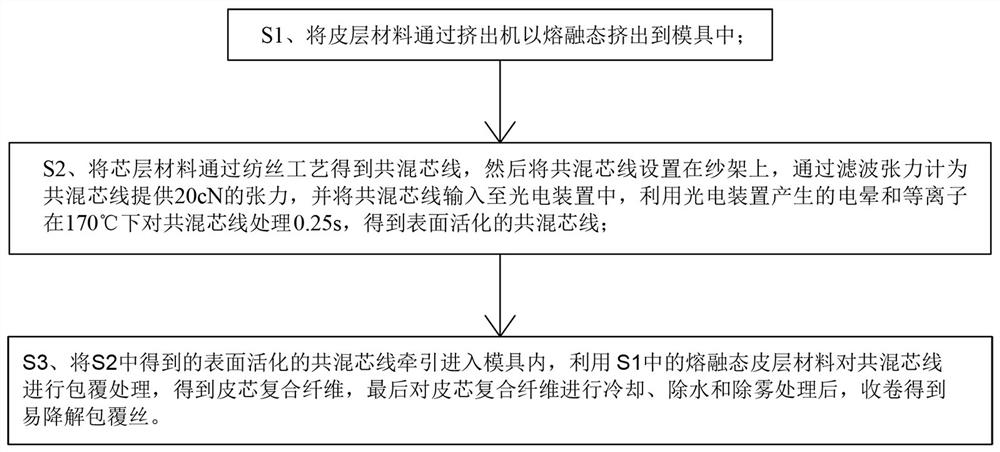

Method used

Image

Examples

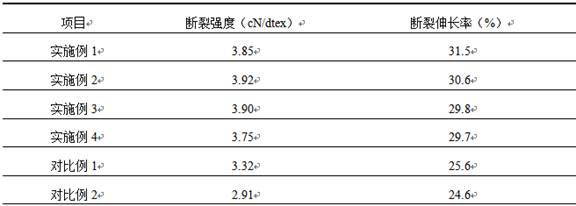

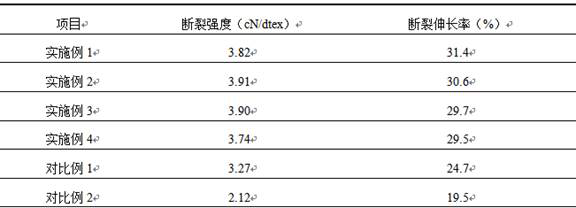

Embodiment 1

[0048] A kind of easily degradable covering yarn, including core layer and cortex:

[0049] The core layer material is PLA / modified mica powder composite material;

[0050] The skin layer material is PBAT / PBS / PCL reactive blend material.

[0051] In this example:

[0052] The preparation method of the PLA / modified mica powder composite material is as follows: the dried PLA and the modified mica powder are melt-blended in a twin-screw extruder to prepare the PLA / modified mica powder composite material, and each section of the screw rod The temperature is 160-190°C, the head temperature is 190°C, and the screw speed is 20r / min. Wherein, the mass ratio of the PLA to the modified mica powder is 100:5.

[0053] The modified mica powder is cationic modified mica powder, and the preparation method of the cationic modified mica powder is as follows: mix mica powder, deionized water, and cationic modifier in a three-necked flask, and stir in a water bath at 75°C for 1.5 h, cooling,...

Embodiment 2

[0060] A kind of easily degradable covering yarn, including core layer and cortex:

[0061] The core layer material is PLA / modified mica powder composite material;

[0062] The skin layer material is PBAT / PBS / PCL reactive blend material.

[0063] In this example:

[0064] The preparation method of the PLA / modified mica powder composite material is as follows: the dried PLA and the modified mica powder are melt-blended in a twin-screw extruder to prepare the PLA / modified mica powder composite material, and each section of the screw rod The temperature is 160-190°C, the head temperature is 190°C, and the screw speed is 20r / min. Wherein, the mass ratio of the PLA to the modified mica powder is 100:6.

[0065] The modified mica powder is cationic modified mica powder, and the preparation method of the cationic modified mica powder is as follows: mix mica powder, deionized water, and cationic modifier in a three-necked flask, and stir in a water bath at 75°C for 1.5 h, cooling,...

Embodiment 3

[0072] A kind of easily degradable covering yarn, including core layer and cortex:

[0073] The core layer material is PLA / modified mica powder composite material;

[0074] The skin layer material is PBAT / PBS / PCL reactive blend material.

[0075] In this example:

[0076] The preparation method of the PLA / modified mica powder composite material is as follows: the dried PLA and the modified mica powder are melt-blended in a twin-screw extruder to prepare the PLA / modified mica powder composite material, and each section of the screw rod The temperature is 160-190°C, the head temperature is 190°C, and the screw speed is 20r / min. Wherein, the mass ratio of the PLA to the modified mica powder is 100:7.

[0077] The modified mica powder is cationic modified mica powder, and the preparation method of the cationic modified mica powder is as follows: mix mica powder, deionized water, and cationic modifier in a three-necked flask, and stir in a water bath at 75°C for 1.5 h, cooling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com