Wood board polishing device

A technology of wood boards and grinding racks, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc. It can solve the problems of health hazards for operators, no centralized dust cleaning mechanism, and difficult maintenance, so as to improve the grinding process. Efficiency, reduced labor intensity, simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

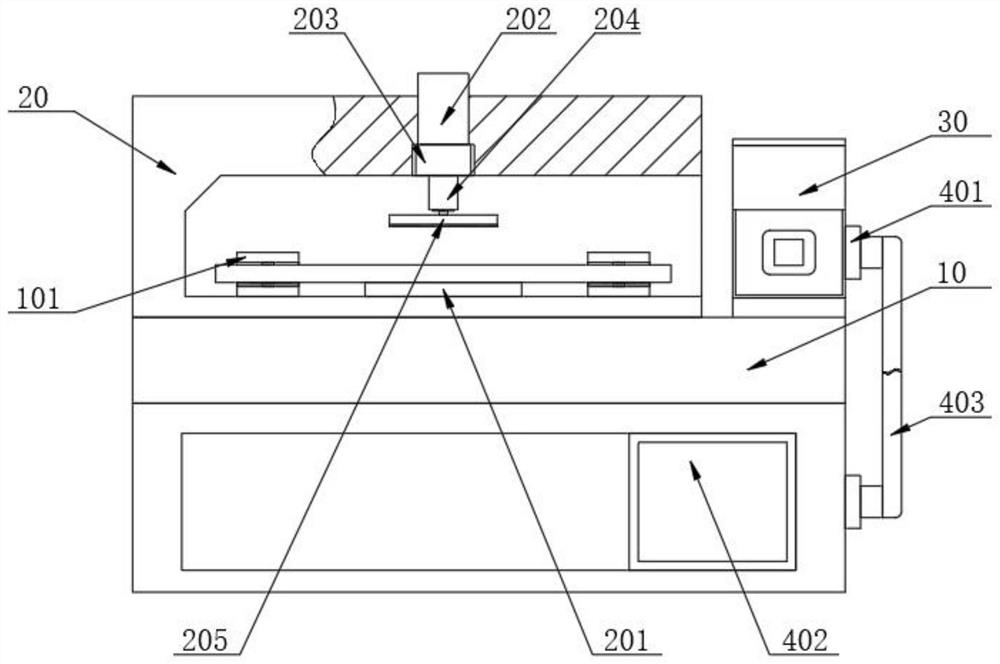

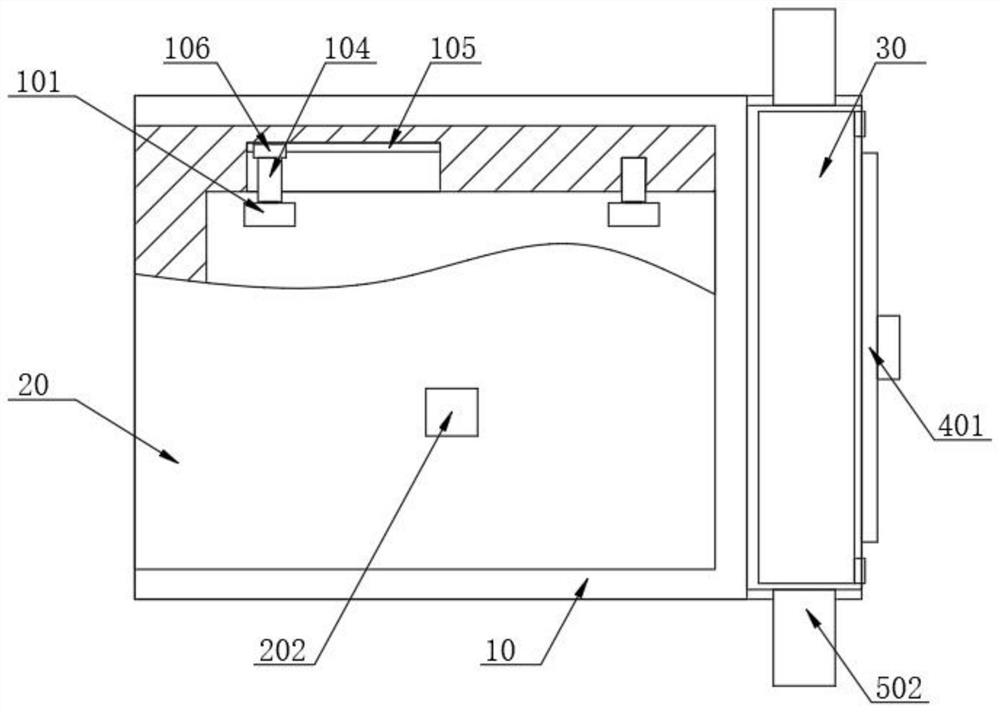

[0032] see Figure 1-6 Shown, a kind of plank polishing device comprises frame 10, discharging frame 20 and polishing frame 30, and discharging frame 20 and polishing frame 30 are all arranged on the top of frame 10, and discharging frame 20 is positioned at the top of grinding frame 30 On the left side, the inside of the discharge rack 20 is provided with a discharge mechanism, and the inside of the discharge rack 20 is also provided with a steering mechanism, the inside of the grinding frame 30 is provided with a grinding mechanism, and the inside of the grinding frame 30 is also provided with a dust suction mechanism, The left side inside the grinding frame 30 is provided with a sealing assembly;

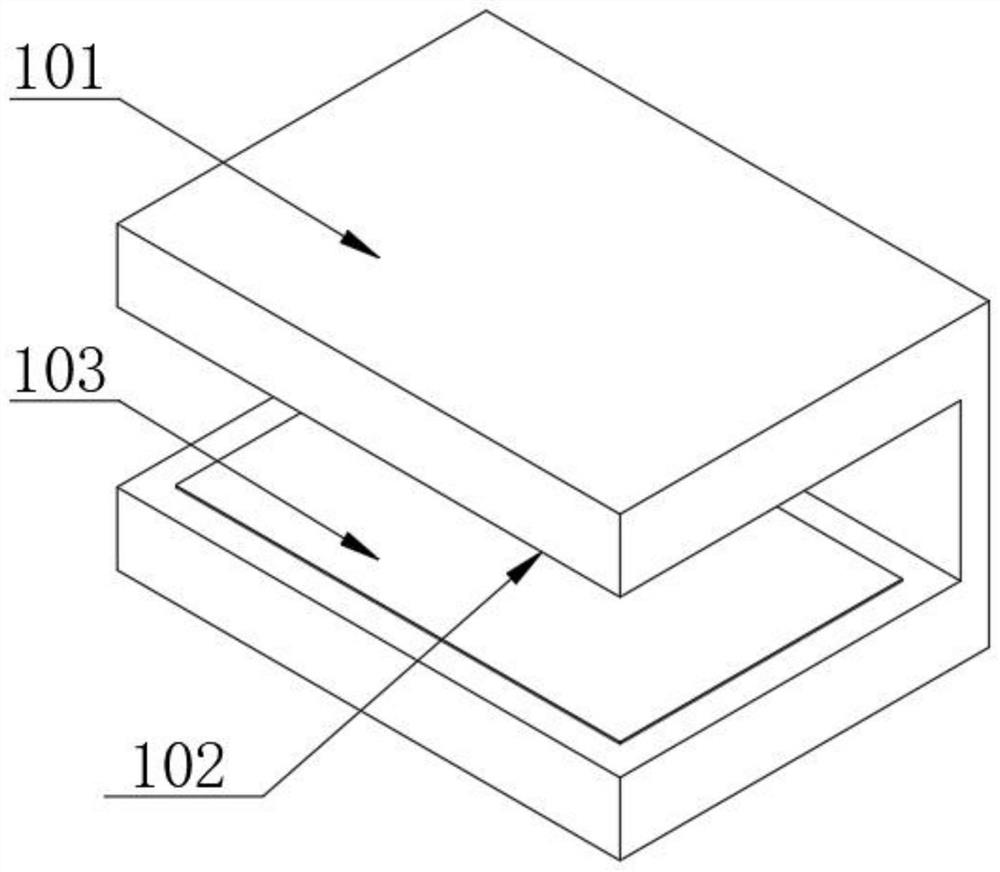

[0033] The discharge mechanism includes two discharge blocks 101 positioned at the rear side of the discharge rack 20, and the inside of the two discharge blocks 101 is provided with a discharge groove 102, and the top and bottom of the discharge groove 102 inner walls are movabl...

Embodiment 2

[0038] As a further supplement to the above-mentioned embodiment, the grinding mechanism in the present invention includes a sanding roller 301 slidingly arranged inside the grinding frame 30, an active groove 302 is opened above the inside of the grinding frame 30, and a second straight line is provided on the top of the inner wall of the movable groove 302. Slide rail 303, one side of the second linear slide rail 303 is slidably provided with a second linear motor 304, and the bottom of the second linear motor 304 is provided with a second servo motor 305, and the inside of the grinding roller 301 is provided with a rotating shaft 306, and The top of the rotating shaft 306 is fixedly connected with one end of the output shaft of the second servo motor 305 through a coupling, and the bottom of the grinding frame 30 inner wall is slidably provided with a movable block 307, and the top of the movable block 307 is rotationally connected with the bottom end of the rotating shaft 30...

Embodiment 3

[0042] As a further supplement to the above-mentioned embodiment, the dust suction assembly in the present invention includes a dust suction frame 401, and one side of the dust suction frame 401 extends to the inside of the grinding frame 30, and the side of the dust suction frame 401 located inside the grinding frame 30 has a Several dust suction ports, the right side inside the frame 10 is provided with a dust collection frame 402, and the right side inside the dust collection frame 402 is provided with a vacuum cleaner, the right side of the dust suction frame 401 is connected with a dust suction pipe 403, and One end of the dust suction pipe 403 communicates with the intake end of the vacuum cleaner;

[0043] When using the grinding mechanism to grind the side of the wood board, the vacuum cleaner cooperates with the suction pipe 403 and the suction frame 401 to generate negative pressure at the suction port, and the dust generated during the grinding process enters the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com