Oppositely-rolling granulator for organic fertilizer

A technology of organic fertilizer and granulator, which is applied to extrusion granulation of raw materials, solid/semi-solid fertilizers, dryers, etc., can solve the problem of poor drying effect of organic fertilizers, difficult to meet the requirements of high material integrity, adhesion And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

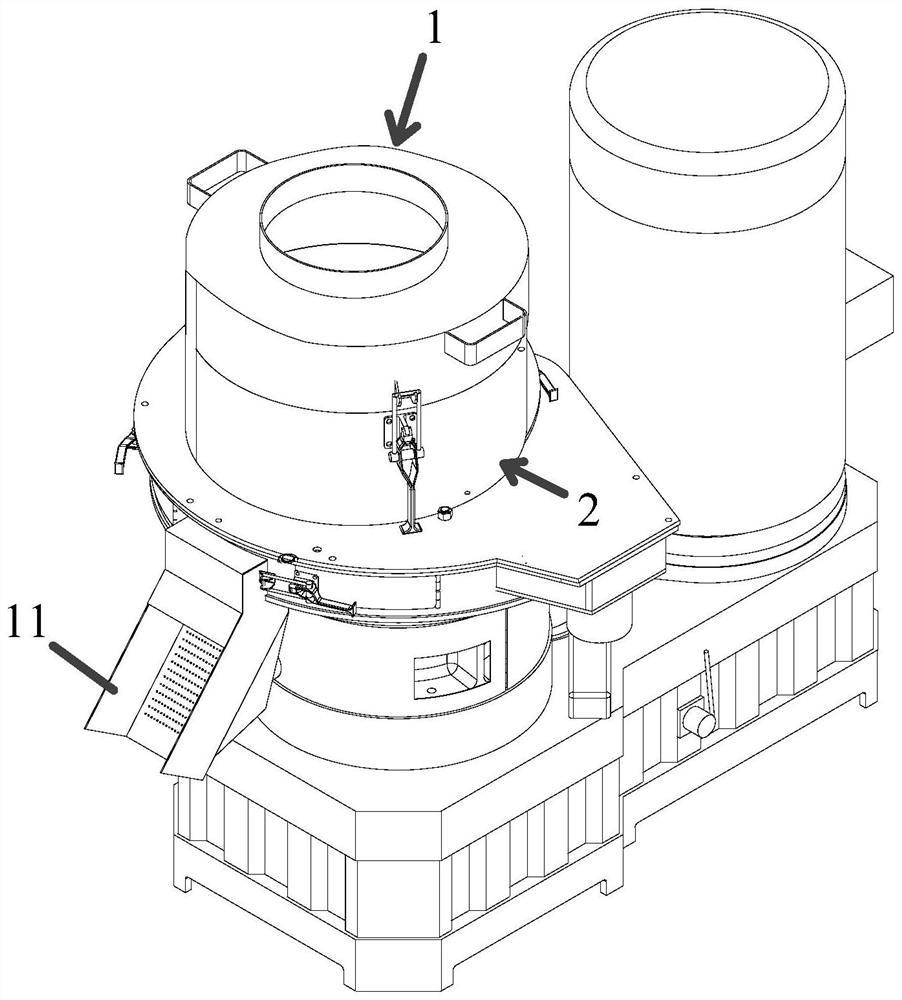

[0042] A counter-roll granulator for organic fertilizers, such as figure 1 shown, which includes:

[0043] Feeding mechanism 1 is used for feeding material into the granulator; in this embodiment, as figure 1 As shown, the feeding port of the feeding mechanism 1 is arranged above the roller granulator; the outlet end of the pressing roller 4 communicates with the discharge hopper 11 which is inclined downward;

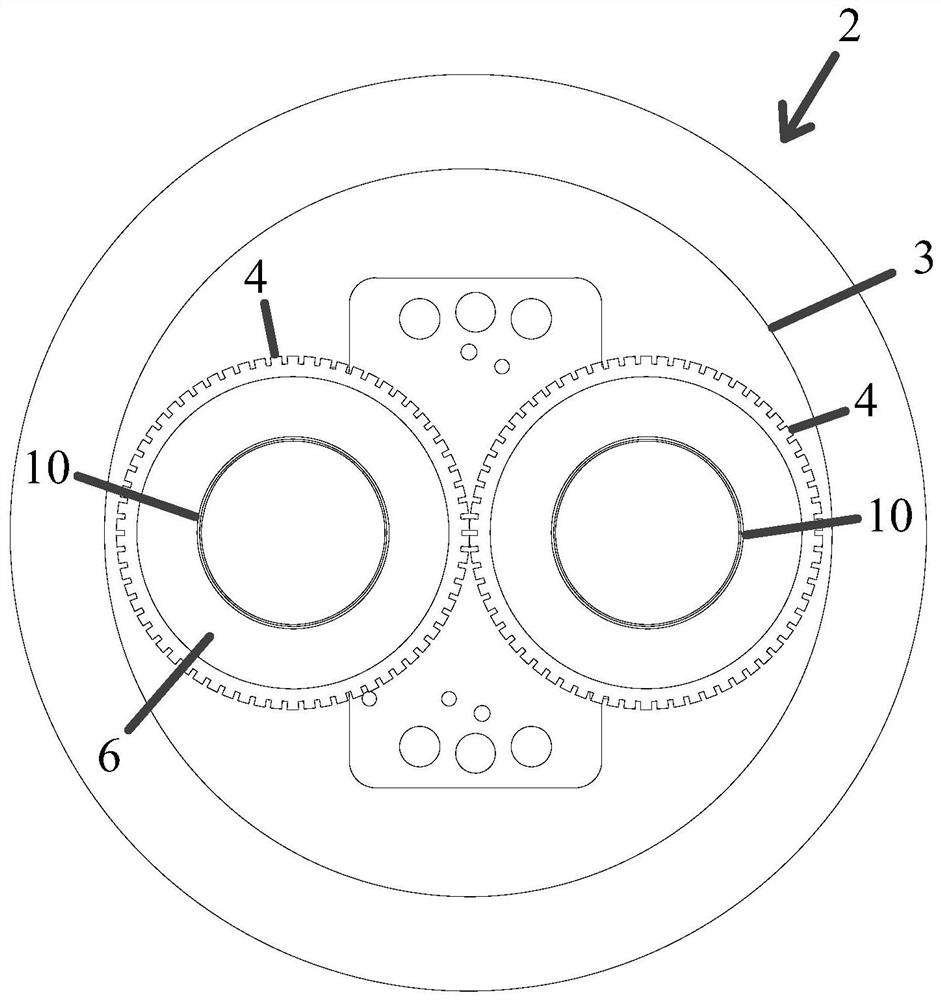

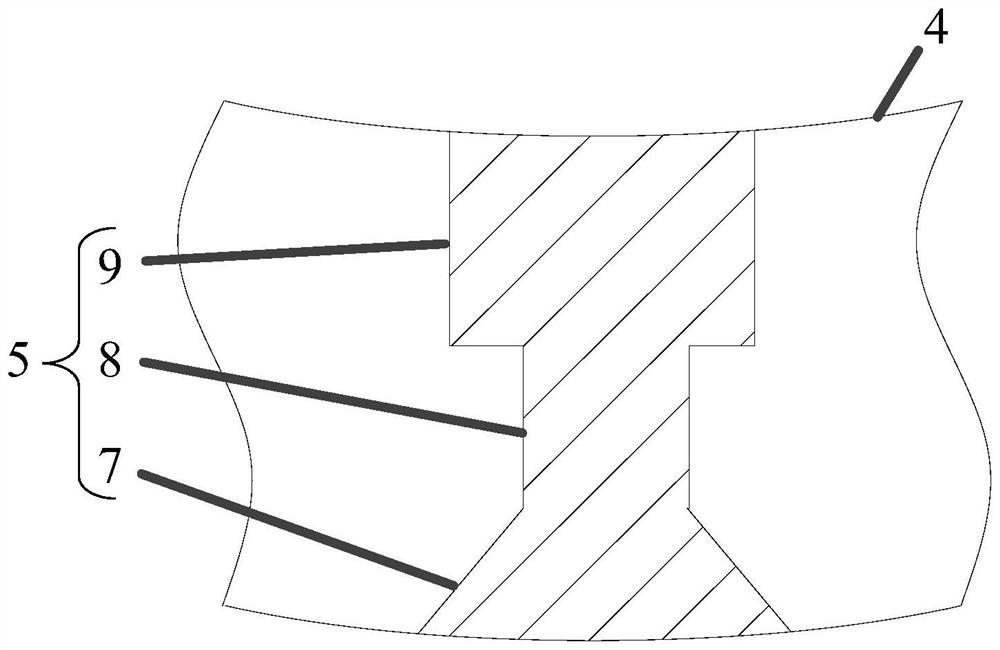

[0044] Forming mechanism 2, used to press and form the material entering the granulator into a preset shape; such as figure 2 and Figure 4 As shown, the molding mechanism 2 includes: a molding chamber 3, a pressure roller 4 arranged in the molding chamber 3 and oppositely arranged, and a drive shaft 10; the outer contour edge of the pressure roller 4 is provided with a material molding hole 5 , and the inside of the pressure roller 4 is provided with a feeding cavity 6 for moving the formed material out of the forming mechanism 2, and the material forming hole 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com