Formaldehyde scavenging agent and preparation method thereof

A formaldehyde scavenger and solution technology, applied in the field of indoor air pollution control, can solve the problems of low formaldehyde removal rate, impact on health, poor long-term effect, etc., and achieve the effect of high formaldehyde removal rate, fast formaldehyde removal speed, and long effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

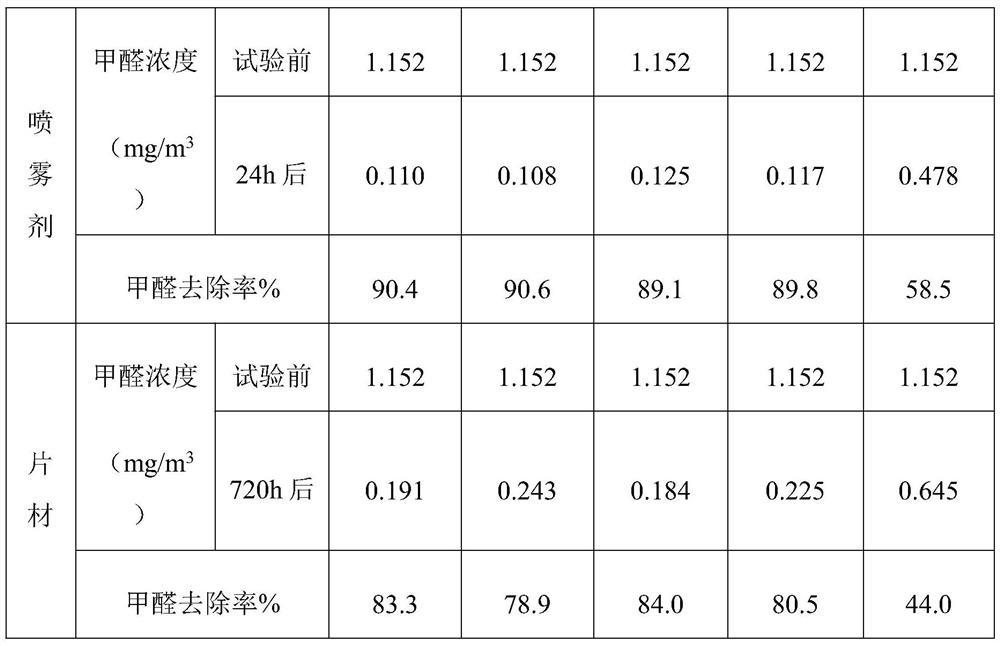

Examples

preparation example Construction

[0015] A preparation method of formaldehyde scavenger, comprising the following steps:

[0016] Disperse biomass carbon powder in alkaline solution, add organic polyamine and mix, the mass ratio of carbon powder to organic polyamine is 10:(0.5-1), react at 180-200°C for 3-6h, cool and centrifuge, The amino carbon quantum dot (N-CQDs) solution is obtained; the N-CQDs solution and the basic amino acid solution are mixed to obtain a formaldehyde scavenger solution.

[0017] In this embodiment, N-CQDs represent amino carbon quantum dots. The alkaline solution is a sodium hydroxide solution with a mass concentration of 2.5%. Under alkaline conditions, the reaction between biomass carbon powder and organic polyamines is more sufficient, so that more amino groups are generated on the surface of carbon quantum dots.

[0018] During cooling and centrifugation, it is to cool to room temperature, and centrifugation is to remove insoluble matter, improve the purity of amino carbon quant...

Embodiment 1

[0039] 1) Preparation of amino carbon quantum dots

[0040] First remove the dust on the surface of the rice husk with deionized water, after drying at 80°C, weigh 50g of rice husk and place it in the reactor, add 250mL of 10% hydrochloric acid, stir mechanically at 60°C for 2h, cool to room temperature, and use Wash with deionized water until neutral, add 250mL of 5% sodium hydroxide solution, stir mechanically at 90°C for 3h, cool to room temperature, wash with deionized water until neutral, and dry the solid at 80°C. The treated and dried rice husks were calcined in a muffle furnace at 300° C. for 3 hours, and cooled to obtain rice husk carbon powder.

[0041] Ultrasonic disperse 5g of rice husk carbon powder in 100mL of 2.5% sodium hydroxide solution, then add 0.25g of ethylenediamine, mix evenly, seal, react at 180°C for 6h, cool to room temperature, and centrifuge to remove insoluble matter to obtain amino carbon quantum Point the N-CQDs solution and dilute it 200 times...

Embodiment 2

[0049] 1) Preparation of amino carbon quantum dots

[0050] First remove the dust on the surface of the peanut shells with deionized water, after drying at 80°C, weigh 50g of peanut shells and put them in the reactor, add 250mL of 10% hydrochloric acid, stir mechanically at 70°C for 2h, cool to room temperature, Wash with deionized water until neutral, add 250mL of 5% sodium hydroxide solution, stir mechanically at 80°C for 3h, cool to room temperature, wash with deionized water until neutral, and dry the solid at 80°C. The dried peanut shells were calcined in a muffle furnace at 400°C for 2 hours, and then cooled to obtain peanut shell carbon powder.

[0051] Ultrasonic disperse 5g of peanut shell carbon powder in 100mL of 2.5% sodium hydroxide solution, then add 0.35g of diethylenetriamine, mix evenly, seal, react at 190°C for 4h, cool to room temperature, and centrifuge to remove insoluble matter to obtain amino carbon Quantum dot N-CQDs solution, diluted 200 times.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com