Lifting appliance for integrally lifting FSRU ship regasification module

An overall hoisting and regasification technology, which is applied in the directions of safety devices, transportation and packaging, load suspension components, etc., can solve the problems of failure to meet verticality and stability requirements, failure to apply regasification modules, failure to meet load requirements, etc. problems, to achieve the effect of increasing the stability and safety of hoisting, saving the construction period, and stabilizing the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

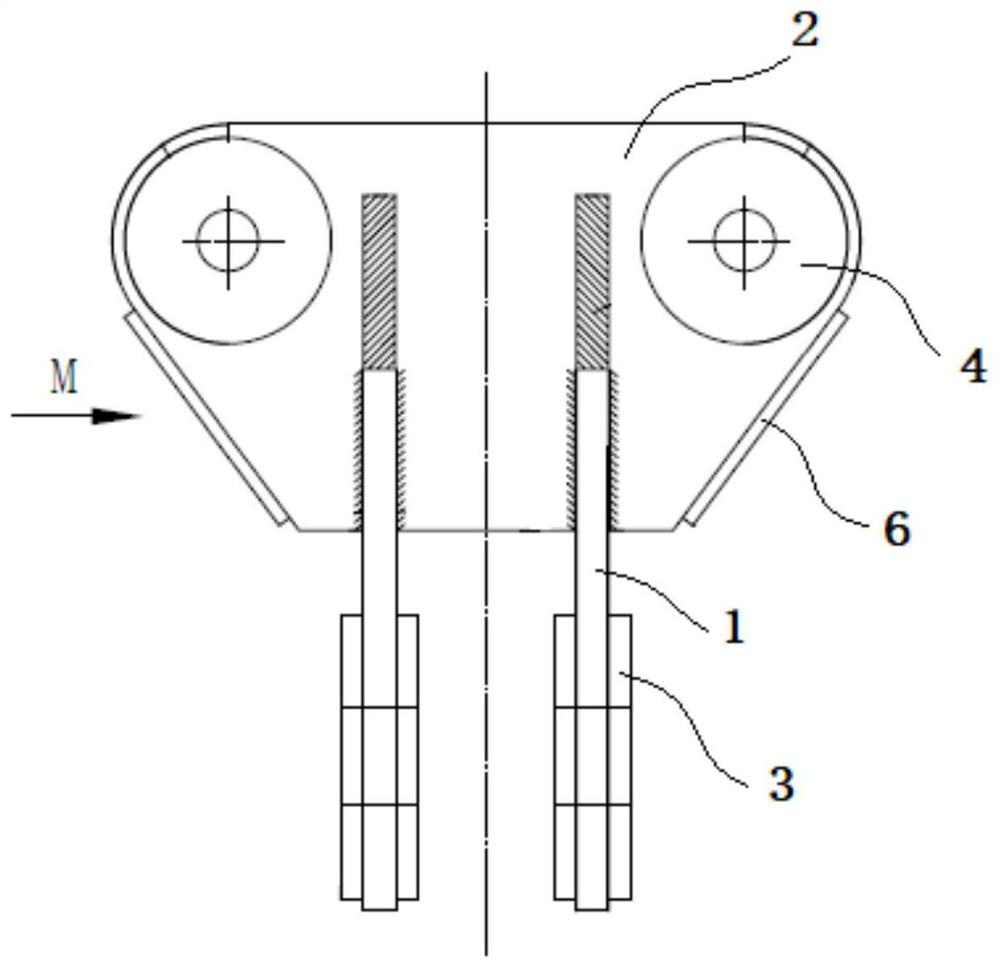

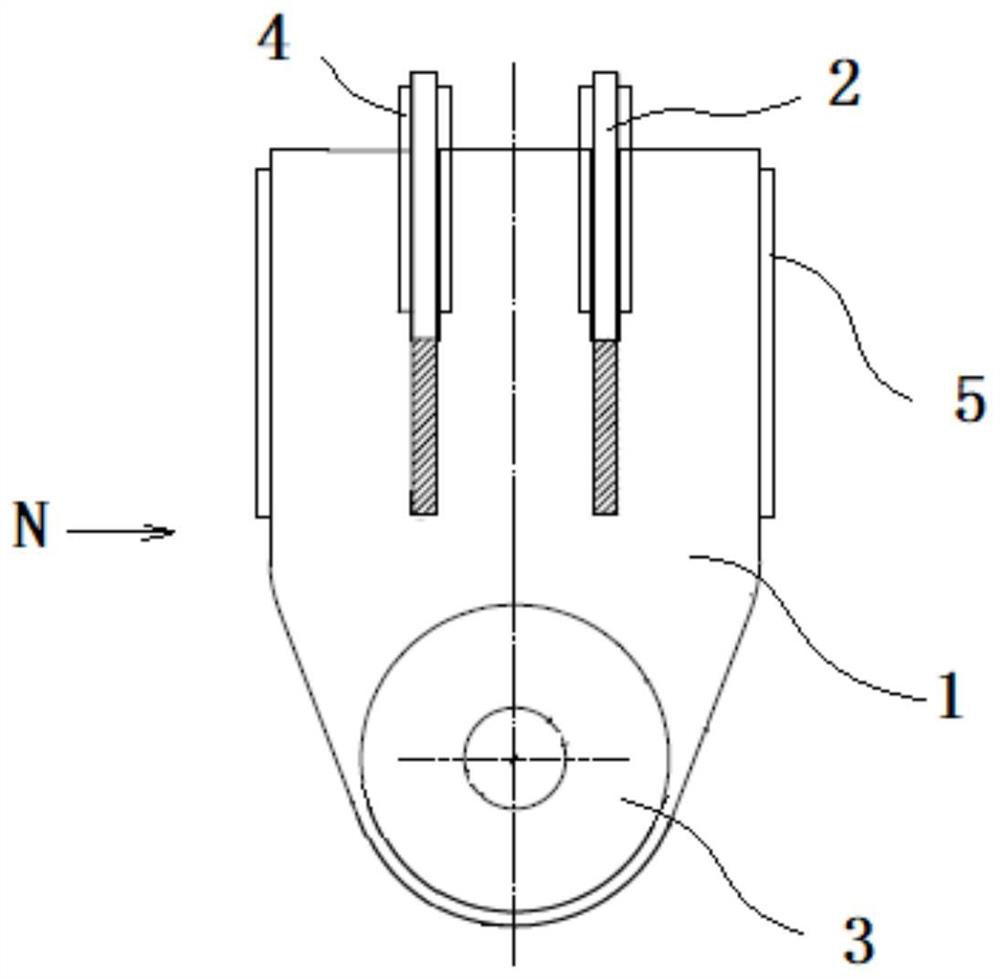

[0044] The spreader of the present invention is used as a special shackle, and in this embodiment, the rated load capacity must be guaranteed to be above 240t, so as to meet the overall hoisting requirements of the regasification module and shorten the shipbuilding period.

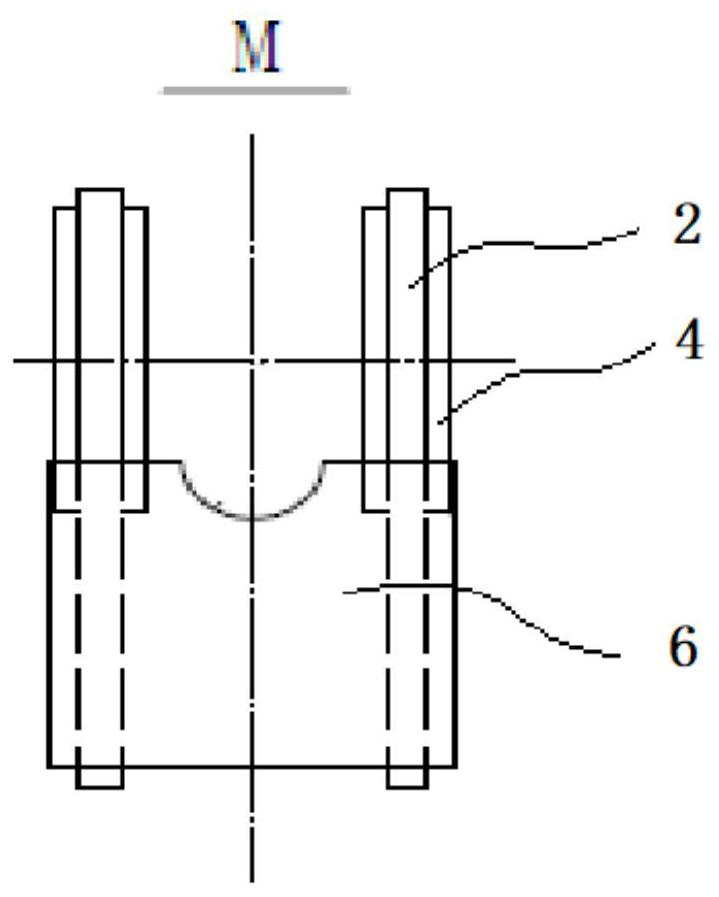

[0045] The main board is similarly D-shaped and symmetrical along the center line. There are 2 pieces in total. The material is AH36, the board thickness is 35mm, and the length×width is 1110×700mm. There are two rectangular grooves of 270×39mm on the short side, the two grooves are symmetrical along the center line, and the distance from the center is 129.25mm. The other end is an arc edge with a radius of 240mm, and a circular hole with a radius of 72.5mm is opened at the midline position 240mm from the apex of the edge. There is a rounded corner with a radius of 200mm at a distance of 594mm from the short side, which is tangent to the arc edge, forming a left-right symmetrical round shoulder.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com