Production method of environment-friendly heavy clean fuel oil for ships

A production method and technology for fuel oil, which are used in fuels, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of wear and tear of internal engine parts, decreased engine lubricity, shortened engine service life, and deteriorated combustion conditions, so as to meet environmental requirements. Effects of protection, increased contact area and opportunity, improved viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

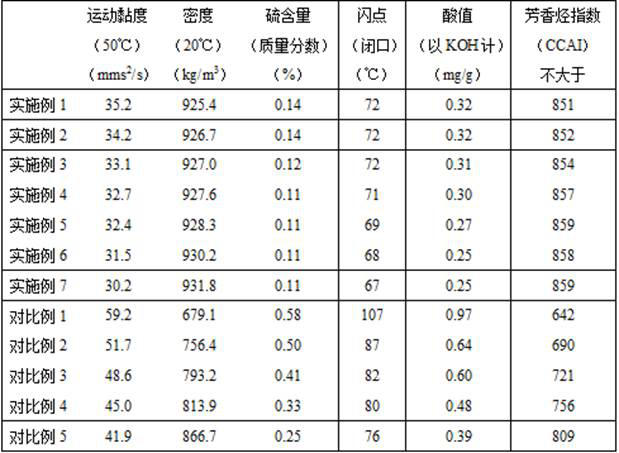

Examples

Embodiment 1

[0069] The production method of the environment-friendly heavy clean bunker fuel oil of the present embodiment comprises the following steps:

[0070] (1) Pretreatment: Prepare fuel oil raw materials and store them safely in accordance with the storage safety technical requirements of chemical products;

[0071] (2) Mechanical impurity removal treatment: filter the fuel oil raw material stored in step (1) to remove impurities;

[0072] (3) Mixing and homogenization treatment: transfer the fuel oil raw material after filtering and removing impurities in step (2) to a homogenization tank;

[0073] (4) Static reaction treatment: The mixed and homogenized fuel oil raw material in step (3) is reacted under nitrogen protection, then statically treated, and cooled to room temperature.

[0074] In the production method of above-mentioned environment-friendly type heavy clean bunker fuel oil,

[0075] The fuel oil raw material described in the step (1) includes the following componen...

Embodiment 2

[0101] The production method of the environment-friendly heavy clean bunker fuel oil of the present embodiment comprises the following steps:

[0102] (1) Pretreatment: Prepare fuel oil raw materials and store them safely in accordance with the storage safety technical requirements of chemical products;

[0103] (2) Mechanical impurity removal treatment: filter the fuel oil raw material stored in step (1) to remove impurities;

[0104] (3) Mixing and homogenization treatment: transfer the fuel oil raw material after filtering and removing impurities in step (2) to a homogenization tank;

[0105] (4) Static reaction treatment: The mixed and homogenized fuel oil raw material in step (3) is reacted under nitrogen protection, then statically treated, and cooled to room temperature.

[0106] In the production method of above-mentioned environment-friendly type heavy clean bunker fuel oil,

[0107] The fuel oil raw material described in the step (1) includes the following componen...

Embodiment 3

[0133] The production method of the environment-friendly heavy clean bunker fuel oil of the present embodiment comprises the following steps:

[0134] (1) Pretreatment: Prepare fuel oil raw materials and store them safely in accordance with the storage safety technical requirements of chemical products;

[0135] (2) Mechanical impurity removal treatment: filter the fuel oil raw material stored in step (1) to remove impurities;

[0136] (3) Mixing and homogenization treatment: transfer the fuel oil raw material after filtering and removing impurities in step (2) to a homogenization tank;

[0137] (4) Static reaction treatment: The mixed and homogenized fuel oil raw material in step (3) is reacted under nitrogen protection, then statically treated, and cooled to room temperature.

[0138] In the production method of above-mentioned environment-friendly type heavy clean bunker fuel oil,

[0139] The fuel oil raw material described in the step (1) includes the following componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com