Preparation method and application of titanium tricarbon di-bismuth sulfide nanocomposite

A nano-composite material, bismuth sulfide technology, applied in the field of tumor near-infrared phototherapy, can solve the problems of low sensitivity and specificity, lack of targeting, etc., to prolong separation time, increase ROS generation, and good biocompatibility. and targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

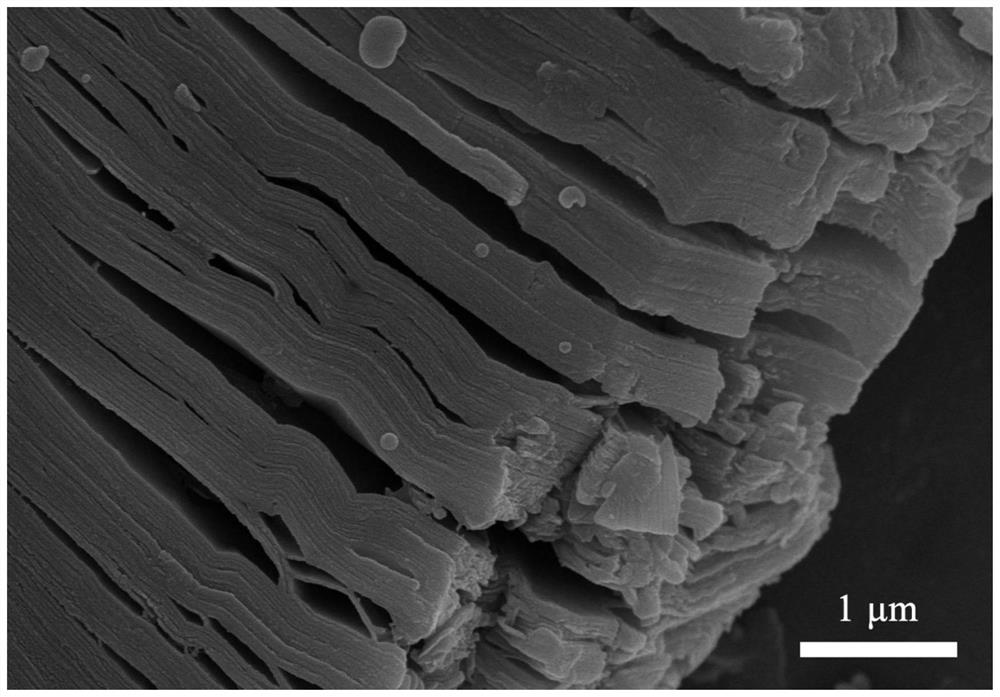

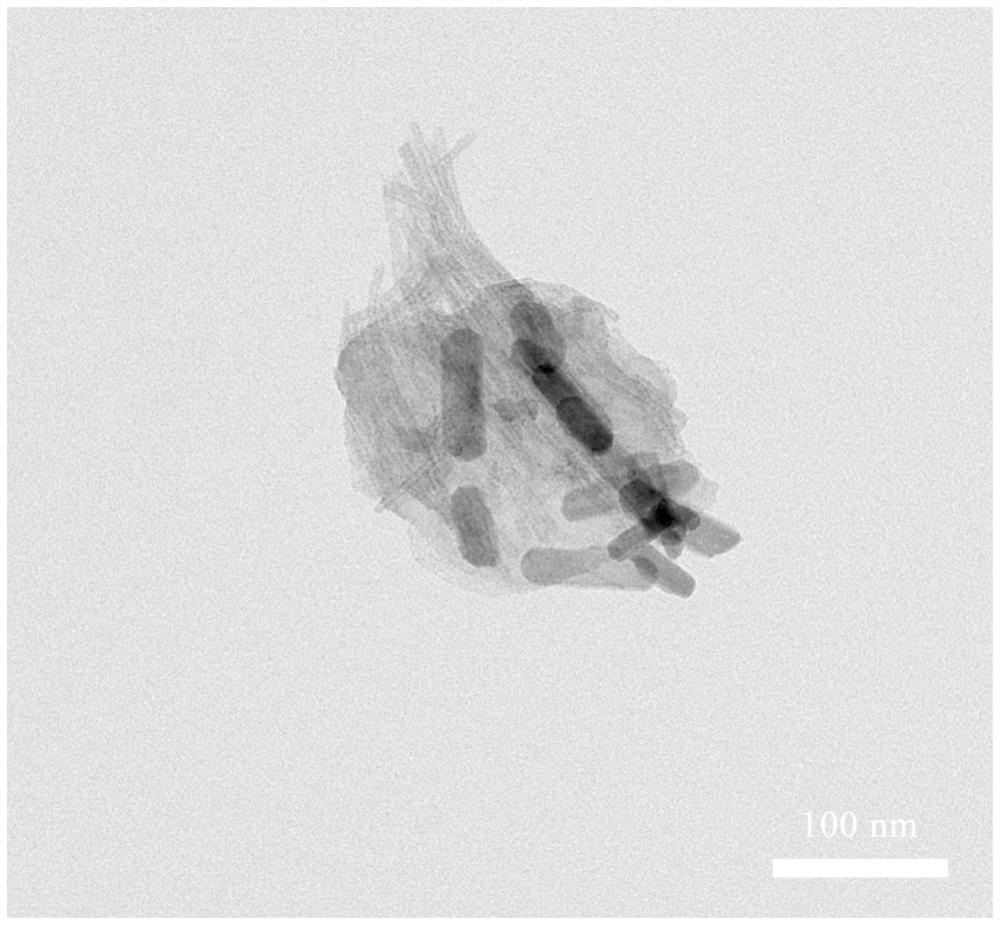

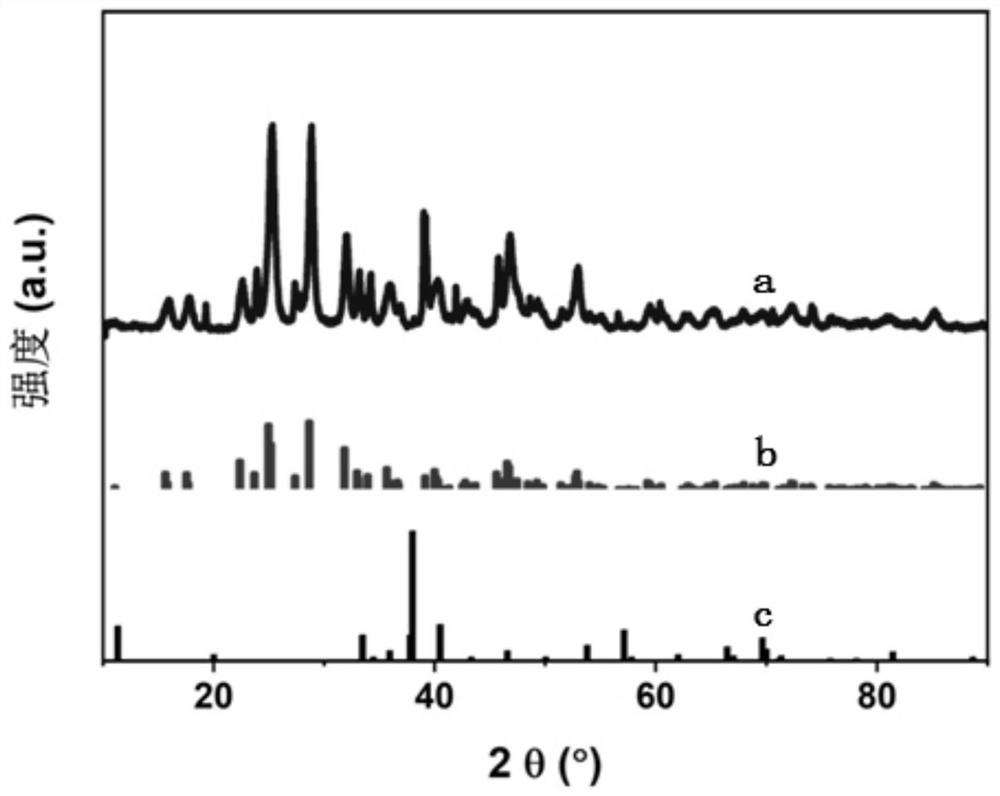

[0018] Embodiment 1: The preparation method of the titanium tricarbon di-bismuth sulfide nanocomposite material of the present embodiment is carried out according to the following steps:

[0019] First, the titanium trialuminum carbon 2 is etched, and then peeled off after the etching treatment; then the oil-soluble titanium tricarbon bismuth sulfide nanocomposite is prepared by the hydrothermal synthesis reaction using the peeled titanium trialuminum carbon 2 as the substrate. Then, the oil-soluble titanium tricarbon-bismuth sulfide nanocomposite was converted into a water-soluble titanium tricarbon-bismuth sulfide nanocomposite, and finally the water-soluble titanium tricarbon-bismuth sulfide nanocomposite was sequentially subjected to mPEG-2K -NH 2 After coating and TPP modification, titanium tricarbon di-bismuth sulfide nanocomposite was obtained.

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific steps of etching titanium trialuminum carbon two are as follows: adding titanium trialuminum carbon two powder to the HCl-LiF mixed solution, at 35 ~ Magnetic stirring for 48-72 hours at a temperature of 38°C, and then repeated centrifugation and washing with deionized water and anhydrous ethanol until the pH was 6-7, to obtain the etched titanium trialuminum carbon 2, and the quality of the titanium trialuminum carbon two powder was the same as that of the powder. The volume ratio of the HCl-LiF mixed solution is 1 g:5 mL, the concentration of HCl in the HCl-LiF mixed solution is 9 mol / L, and the concentration of LiF is 100 g / L.

[0021] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the specific steps of peeling off the etched titanium trialuminum carbon 2 are as follows: put the etched titanium trialuminum carbon 2 into the tetrapropylene In the base ammonium hydroxide solution, magnetic stirring at room temperature (23 ~ 25 ℃) for 48 ~ 72h, to obtain the peeled titanium trialuminum carbon two, the quality of the etched titanium tri aluminum carbon two and tetrapropyl ammonium hydroxide The volume ratio of the solution was 1 g:5 mL.

[0023] Other steps are the same as in the first or second embodiment.

[0024] In the second to third embodiments, Ti3Al2C2 is etched and peeled off to obtain Ti3C2 nanosheets, which enhances its electrical conductivity and prolongs the electron-hole effect of the nanocomposite material under near-infrared light irradiation. separation time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com