Field-domain-concentrated direct-writing type micro-electrochemical machining method and field-domain-concentrated direct-writing type micro-electrochemical machining device

A micro-electrolysis and processing device technology, applied in electrochemical processing equipment, processing working medium, metal processing equipment, etc., can solve the problems of difficult to control the flow of electrolyte, reduced effective utilization of energy, low processing accuracy, etc., to improve the current Density and energy transfer, stray corrosion reduction, high capacity utilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

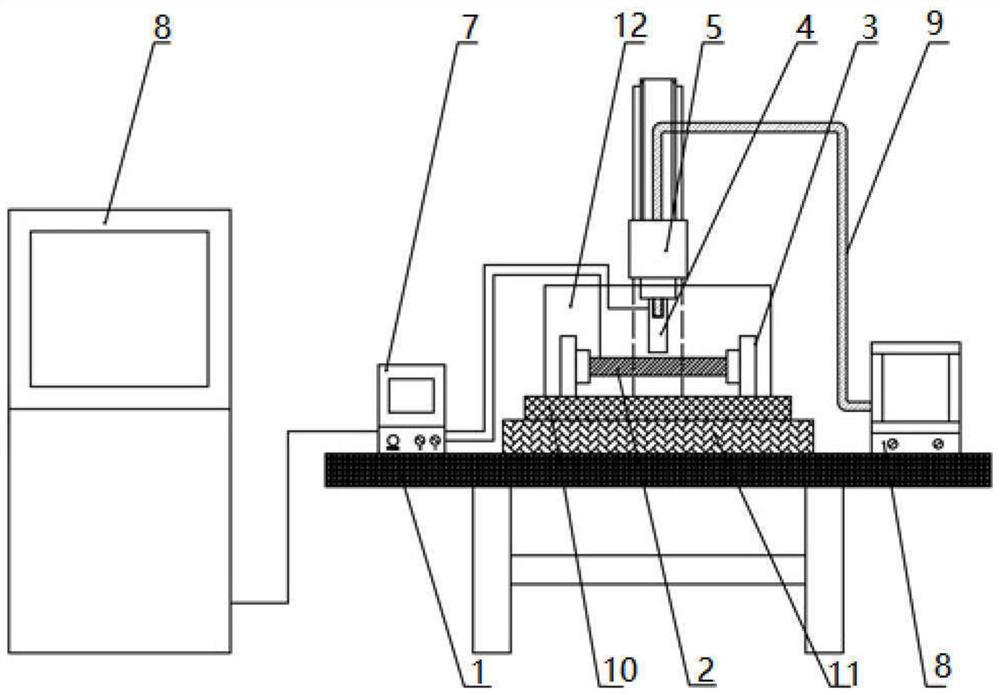

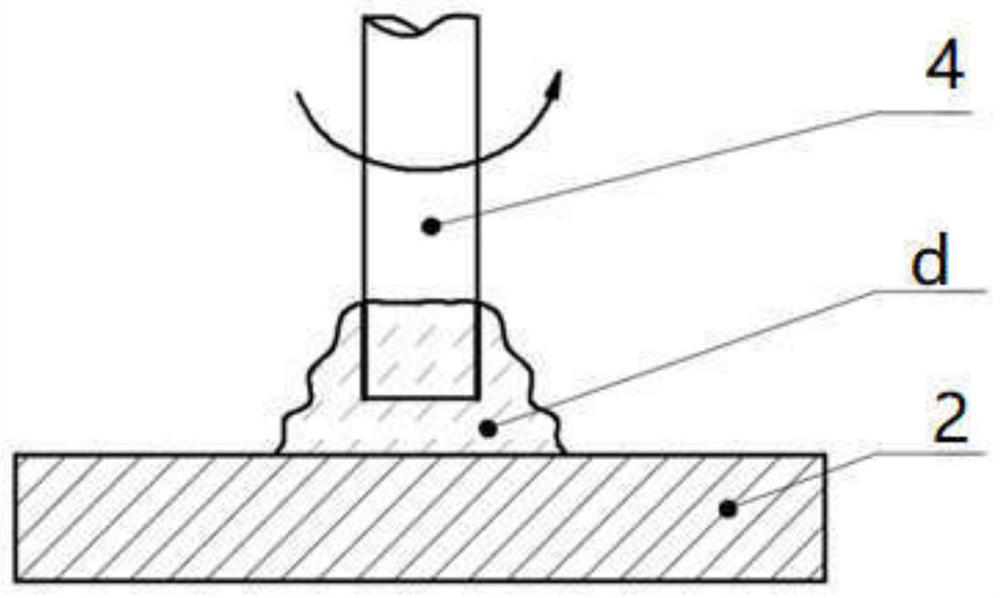

[0041] see Figure 2-4, the field-focused direct-writing micro-electrolytic machining device of this embodiment includes a workbench 1, a clamping mechanism 3 for clamping a workpiece 2, and a spindle drive mechanism for driving the tool 4 to move above the workpiece 2 5. An electrolytic medium supply mechanism 6 for supplying polymer electrolytic medium, a processing power supply 7 and an integrated control cabinet 8 .

[0042] The clamping mechanism 3 is arranged on the workbench 1. Specifically, the clamping mechanism 3 may adopt a structure in the prior art.

[0043] The electrolytic medium supply mechanism 6 includes an electrolytic medium preparation mechanism and an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com