Simple preparation method and application of gold powder

A gold powder, a simple technology, applied in the field of simple preparation of gold powder, can solve the problems of the influence of gold powder conductivity, high organic content of gold powder, complicated preparation process, etc., and achieve the effect of good conductivity, low organic content and excellent work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for preparing gold powder preparation of the present embodiment, concrete implementation steps are as follows:

[0034] (1) Prepare reducing agent solution A: first add 2L of deionized water into the reactor, add 30g of sodium sulfite, stir and dissolve completely, and obtain reducing agent solution A;

[0035] (2) Preparation of gold-containing solution B: dilute the chloroauric acid solution with deionized water, and configure it into a chloroauric acid solution with a pH value of 0.6-1 and a concentration of 100 g / L to obtain gold-containing solution B;

[0036] (3) Take 0.5L gold-containing solution B and add it to the prepared reducing agent solution A at 25mL / s. During the reaction, the temperature is kept between 60-100°C. After the reaction is completed, wash it with deionized water and alcohol successively Precipitate (gold powder), and dry at 60 ° C, that is.

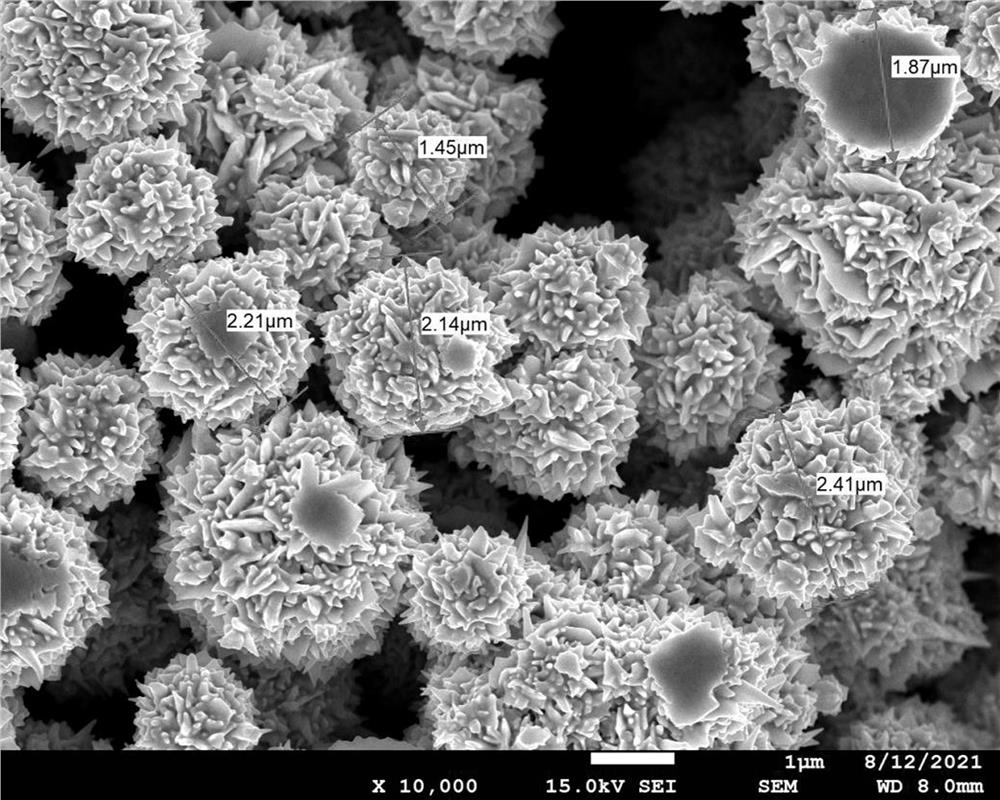

[0037] The obtained gold powder particles are as figure 1 As shown, the physical proper...

Embodiment 2

[0042] In this embodiment, the gold powder prepared in Example 1 is tested for organic matter content by the thermogravimetric method, and the specific testing process is as follows:

[0043] After the gold powder is placed in a high temperature environment of 400°C for 1 hour, the difference in weight before and after weighing is the organic content.

[0044] As a result of testing, the organic content in the prepared gold powder was 0.12%. It can be seen that the organic content in the prepared gold powder is extremely low and has better electrical conductivity.

Embodiment 3

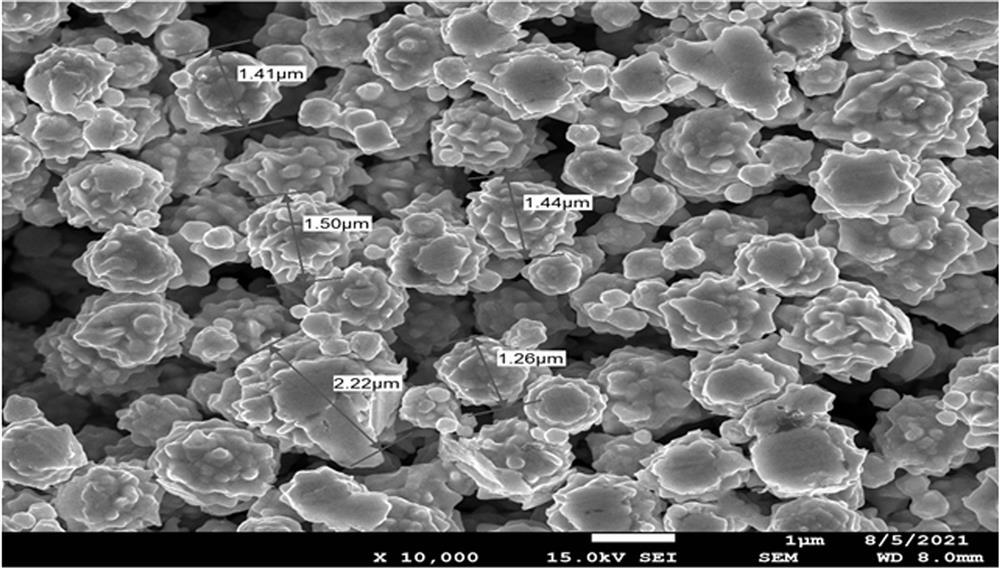

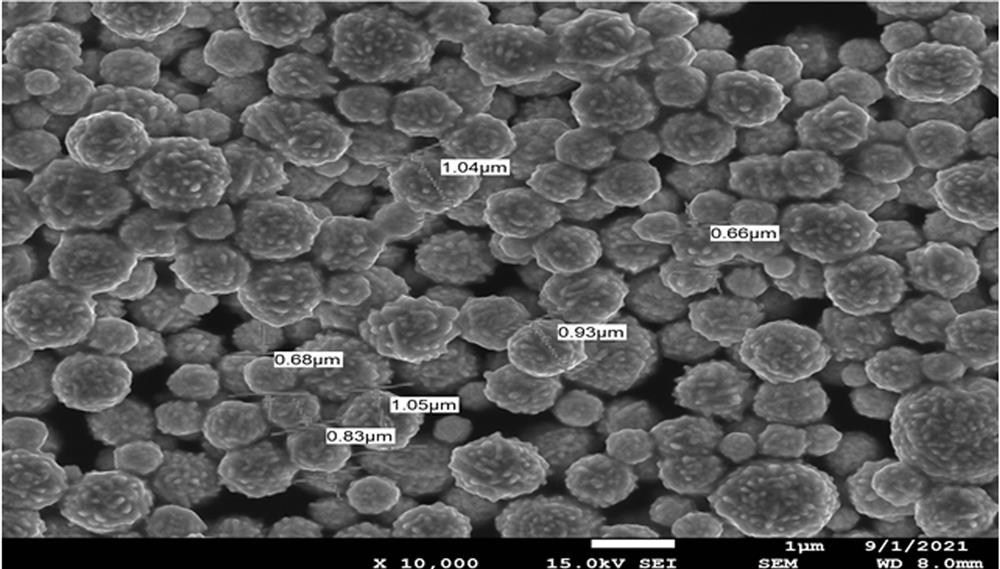

[0046] In order to verify the influence of adding a dispersant to the reducing agent in the present embodiment on the preparation of gold powder, no dispersant is added to the reducing agent solution B during the preparation of the gold powder. The dispersant is specifically hydroxymethyl cellulose, gelatin, A kind of in gum arabic, other preparation process and composition consumption are the same as embodiment 1, and the gold powder particle that obtains is as follows figure 2 , image 3 , Figure 4 As shown, the physical properties of the gold powder are as follows:

[0047] Table 2 Physical properties of gold powder prepared without adding dispersant

[0048]

[0049] Depend on Figure 2~4 It can be seen from the data in Table 2 that if carboxymethyl cellulose is used as a dispersant, the particle size of the prepared gold powder is too small and the span is too large. During the sintering process, it may cause partial burning and partial non-burning, and the resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com