Tail jacking system and spinning machine tool with tail jacking system

A technology of spinning machine tool and tail top, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of processing breakage, inconvenient fixing, unstable mechanical properties, etc., achieve reasonable structure setting, and avoid wear and scratches , Optimize the effect of edge closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

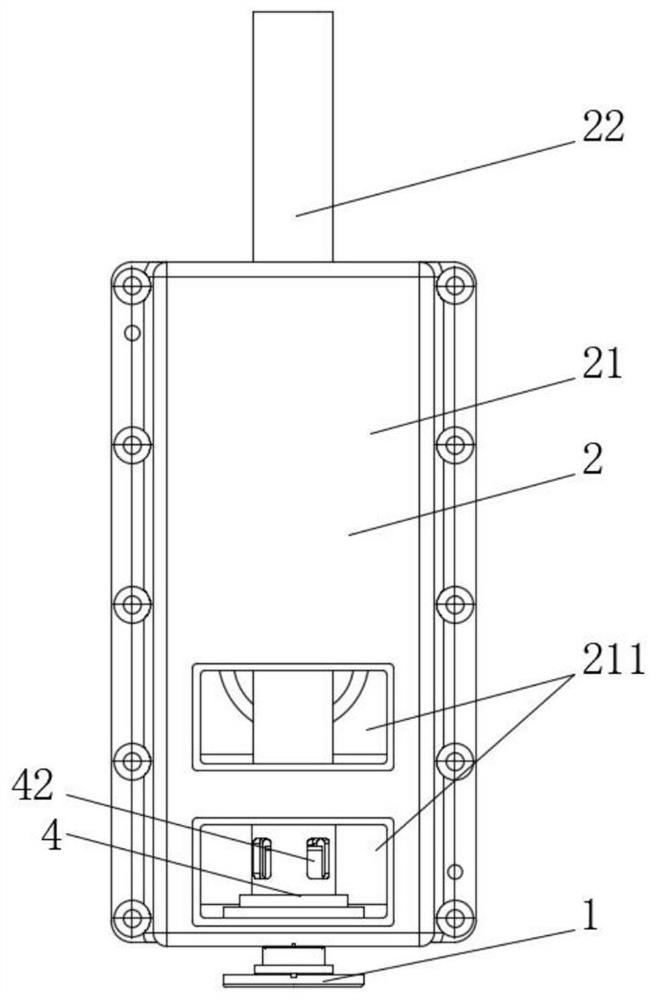

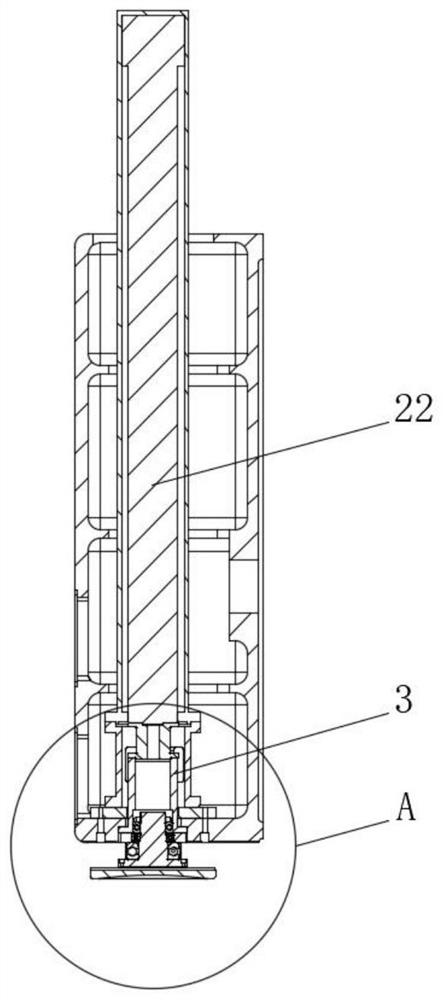

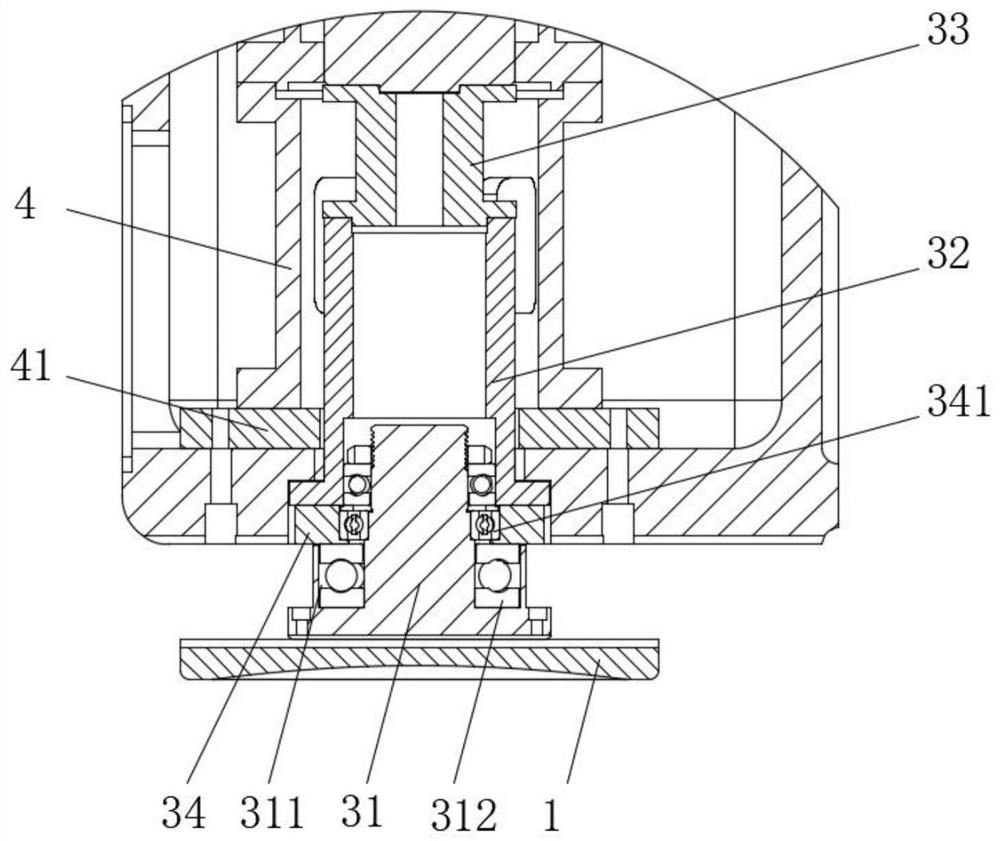

[0028] Such as figure 1 and figure 2 As shown, the tail jacking system of this embodiment is installed on the balance beam of the spinning machine tool, includes a fixed plate 1 for pressing the workpiece on the mold, and also includes a drive assembly 2, which drives the fixed plate 1 along the The rotary shaft of the mold moves axially to compress or loosen the workpiece. In the edge spinning process, after the edge finishing mold is installed on the rotary table, the semi-finished workpiece is hoisted onto the mold, and the surface of the molded workpiece and the surface of the mold are used to achieve a certain circumferential positioning and centering, and then fixed The plate 1 moves and presses the workpiece, so that the end face of the workpiece and the end face of the mold fit together, so as to realize the fixed positioning in the axial direction and ensure the stability of the edge processing of the workpiece. And the fixed plate 1 is rotatably connected to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com