Indium phosphide quantum dot electroluminescent device based on tin oxide as electron injection layer and preparation of indium phosphide quantum dot electroluminescent device

A technology of electroluminescent devices and electron injection layers, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of InP quantum dot light-emitting diode device structure adjustment and optimization research, and achieve an improvement The effect of electroluminescent efficiency, enhanced electron transmission, and reduced turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

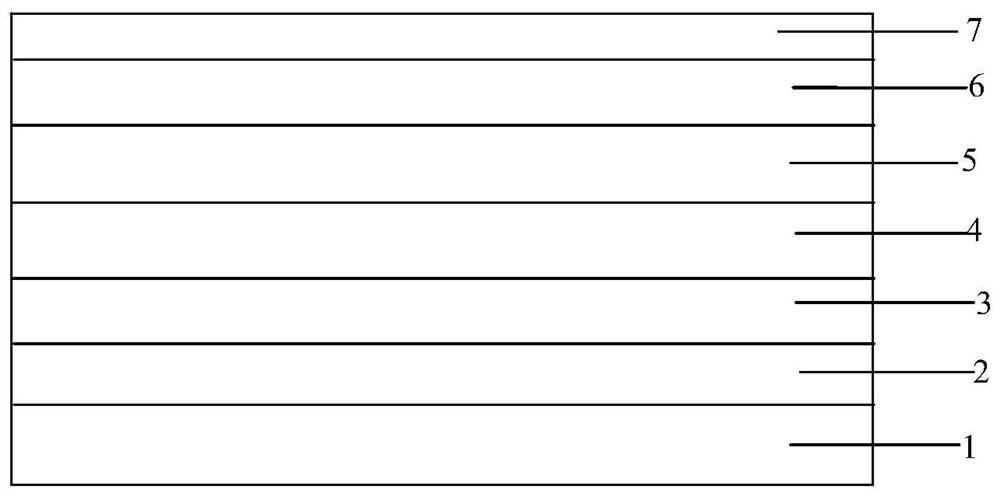

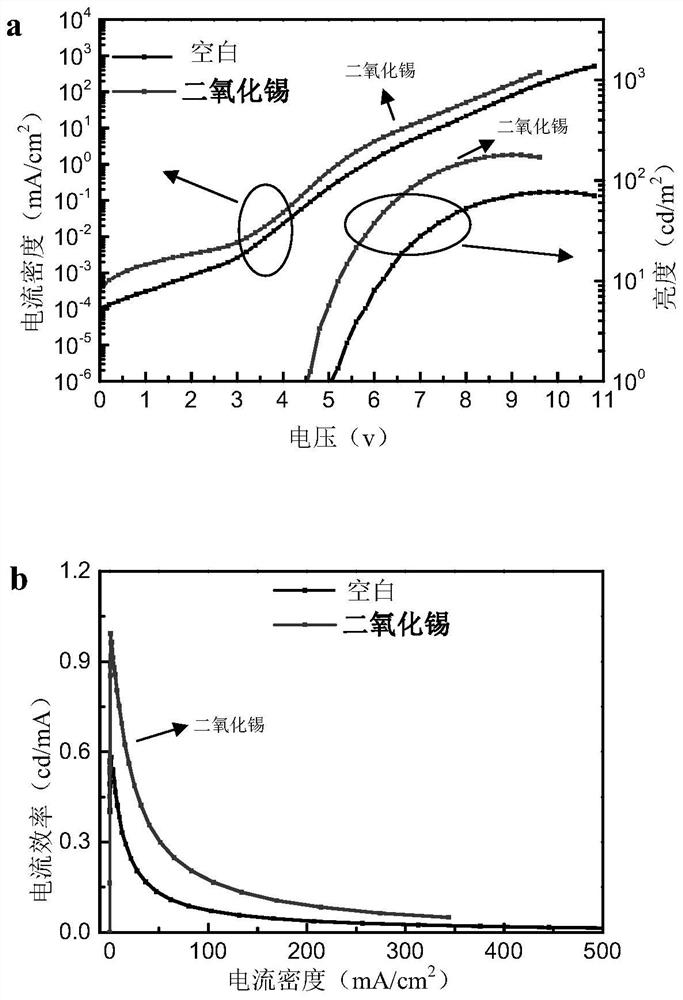

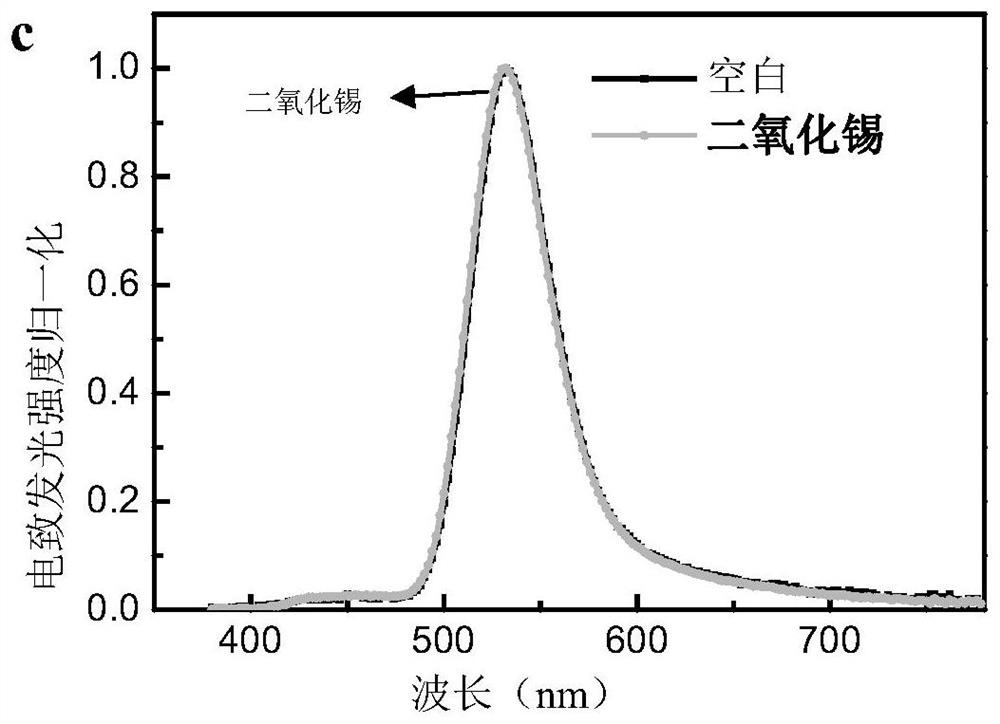

[0031] select figure 1 The device structure shown above uses an ITO substrate and ultrasonically cleans it with lotion, deionized water, and isopropanol for 10 minutes to remove surface pollutants. After drying with high-pressure nitrogen, use oxygen plasma to modify the surface, and then Spin-coat tin dioxide (particle size about 3-5nm) in the glove box as the electron injection layer (thickness ~40nm), the solvent used is ethanol; then spin-coat zinc and magnesium oxide on the tin dioxide as the electron transport layer (thickness ~50nm ), the solvent used is ethanol, and the green light indium phosphide quantum dot material is spin-coated on the zinc magnesium oxide to prepare the quantum dot light-emitting layer (the green light InP / ZnS quantum dot of the core-shell structure), and the solvent used is n-octane (thickness ~ 30nm) , and finally in the high vacuum evaporation chamber (3×10 -4 Pa) The hole transport layer 4,4',4"-tris(carbazol-9-yl)triphenylamine (thickness ~...

Embodiment 2

[0034] select figure 1 The device structure shown in the figure uses an ITO substrate, which is ultrasonically cleaned with lotion, deionized water, and isopropanol for 10 minutes to remove surface pollutants. After drying with high-pressure nitrogen, it is surface-modified with oxygen plasma, and then sprayed The method is to spray tin dioxide on the ITO as an electron injection layer (thickness ~ 40nm), the solvent used is ethanol, then transfer the substrate to a nitrogen glove box, and then spin-coat zinc and magnesium oxide on the tin dioxide as an electron transport layer (thickness~50nm), the solvent used is ethanol, spin-coats green light indium phosphide quantum dot material on zinc magnesium oxide to prepare quantum dot luminescent layer, used solvent is n-octane (thickness~30nm), finally in high vacuum evaporation chamber ( 3×10 -4 Pa) The hole transport layer 4,4',4"-tris(carbazol-9-yl)triphenylamine (thickness ~50nm), the hole injection layer MoO x (thickness ~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com