Ultraviolet aging test method for asphalt with control group

An aging test and control test technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems that affect the test progress, affect the authenticity of test data results, and the asphalt sample cannot be evenly washed by water, etc., and achieve comprehensive reliability. The effect of evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

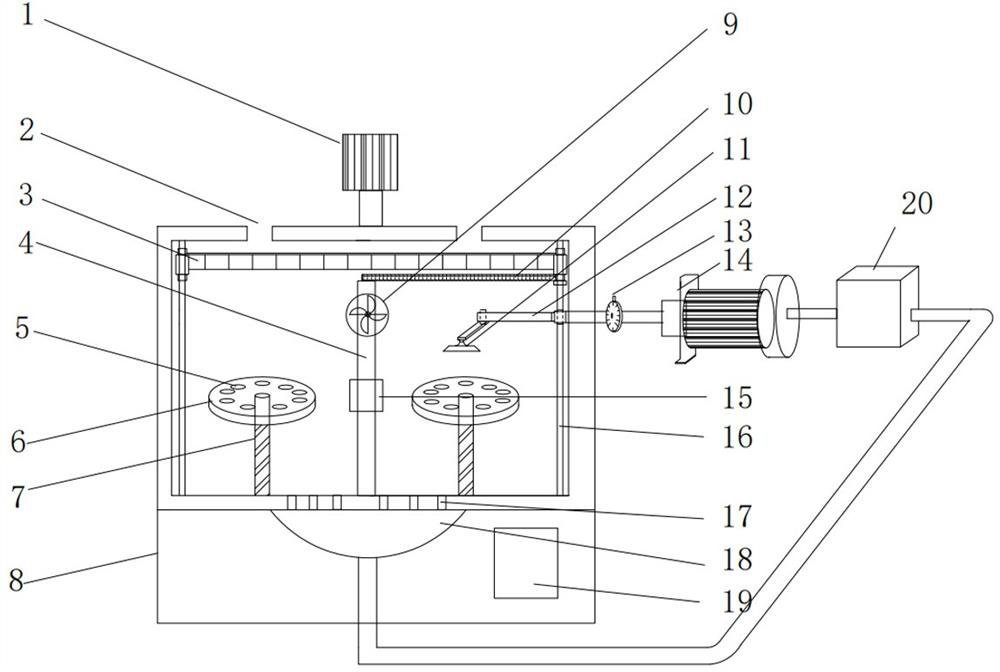

[0038] Example 1, such as figure 1 As shown, the invention provides a kind of asphalt ultraviolet aging test method that has control group, specifically comprises the following steps:

[0039] Step S1: First prepare multiple asphalt specimens, first pour the mixed asphalt into a circular tray to form a mold, and then divide the molded asphalt specimens into two groups on average, one group is the asphalt UV aging test group, and the other The group is the asphalt aging control test group. In this embodiment, 18 asphalt specimens were prepared, which were equally divided into two groups of 9 specimens, which were used for the ultraviolet aging test and the control test respectively. The asphalt specimen is a cylinder with a height of 30 mm and a diameter of 80 mm.

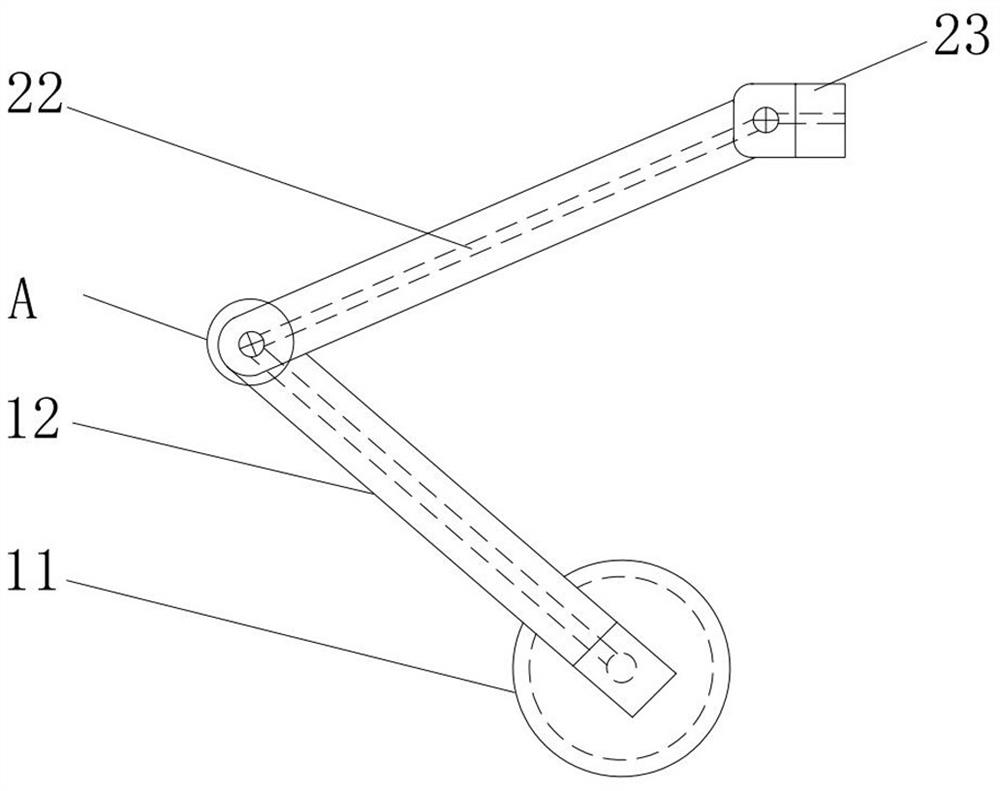

[0040]Step S2: Put two groups of asphalt test pieces into the corresponding test area in the test box 8, specifically, the interior of the test box 8 is divided into two asphalt samples arranged side by side by th...

Embodiment 2

[0049] Embodiment 2, a kind of asphalt ultraviolet aging test method that has control group, differs from embodiment 1 in that: in described step S2, the operating steps when two groups of asphalt specimens carry out comparative test during aging process include: Keep the test environment in the asphalt UV aging test area unchanged, and install a filter glass 10 above the inside of the asphalt aging control test area. Specifically, the filter glass 10 is set on the upper right side of the partition 4, and one end of the filter glass 10 On the top of the partition 4, the other end is detachably installed on the support rod 16 on the right side, so as to facilitate the removal and installation of the filter glass 10 during the test. The filter glass 10 is used for isolating the ultraviolet rays emitted by the high-pressure mercury lamp 3, and is used for test comparison. Then during the test, the high-pressure mercury lamp 3 was turned on, and steps S3 and S4 were repeated, and ...

Embodiment 3

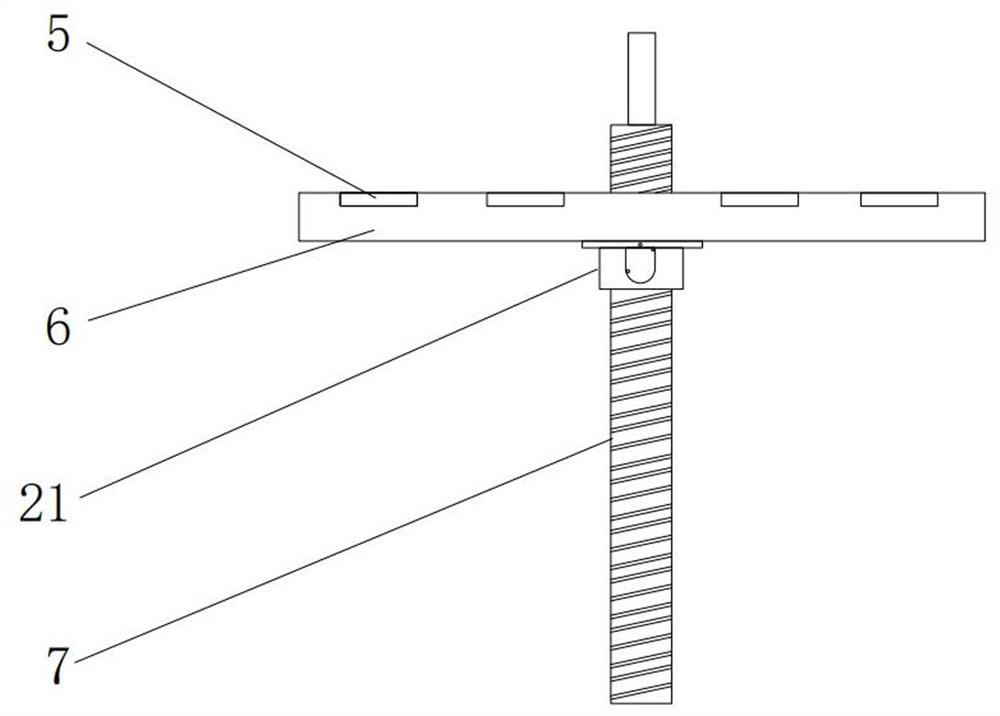

[0051] Embodiment 3, a kind of asphalt ultraviolet aging test method with control group, differs from embodiment 1, 2 in that: in said step S2, the operating steps when two groups of asphalt test pieces are compared in the aging process Including: adjusting the distance between the two sets of loading discs 6 and the high-pressure mercury lamp 3 by rotating the nuts 21 under the two sets of loading discs 6, wherein the asphalt specimens of the asphalt ultraviolet aging test group and the high-pressure mercury lamp 3 The distance between them is adjusted to 50mm-70mm, and the distance between the asphalt specimens of the asphalt aging control test group and the high-pressure mercury lamp 3 is adjusted to 80mm-100mm. Then turn on the high-pressure mercury lamp 3, and repeat steps S3 and S4 to test and compare the influence of different ultraviolet irradiation heights on the ultraviolet aging performance of asphalt under the same temperature, humidity and infrared irradiation cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com