Hydraulic system of cleaning and sweeping vehicle

A hydraulic system and technology for washing and sweeping cars, which is applied in the field of washing and sweeping cars, and can solve problems such as serious energy consumption of the system, system temperature rise, and changing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

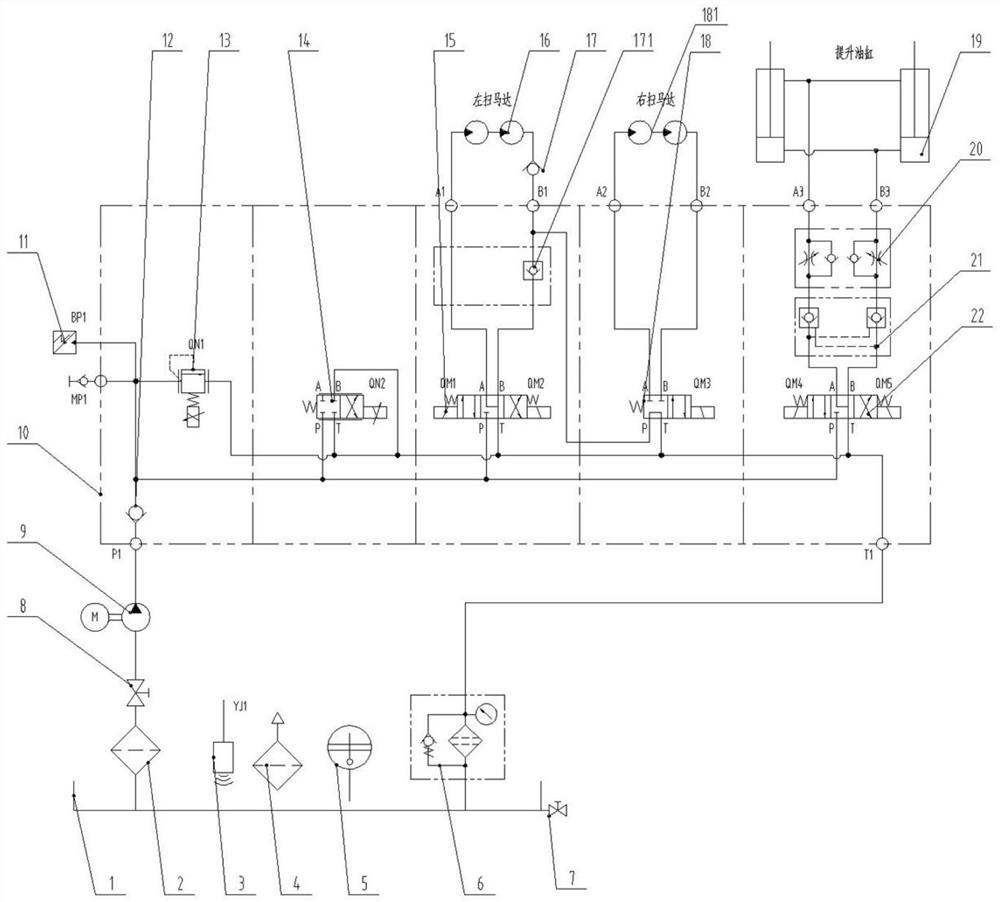

[0033] [First Embodiment] A hydraulic system for washing and sweeping vehicles, such as figure 1 , 2As shown, it includes an integrated hydraulic oil tank 1; an oil pump 9; at least one sweeping motor, which is used to drive the brush; a valve group 10, which is used to adjust the pressure and speed of the sweeping motor; a pressure sensor 11. The pressure sensor 11 is used to monitor the working pressure of the hydraulic system; among them, the integrated hydraulic oil tank 1, the oil pump 9, the valve group 10, the sweeping motor, and the pressure sensor 11 are connected through the oil circuit.

[0034] In the above embodiments, the integrated hydraulic oil tank 1 is an oil tank for storing hydraulic oil, and hydraulic oil is an important medium flowing in the oil circuit, and the hydraulic oil is transported in the oil circuit to realize the purpose of controlling the hydraulic system. The oil pump 9 is a single gear oil pump 9, the price is relatively cheap, it can save ...

no. 3 example

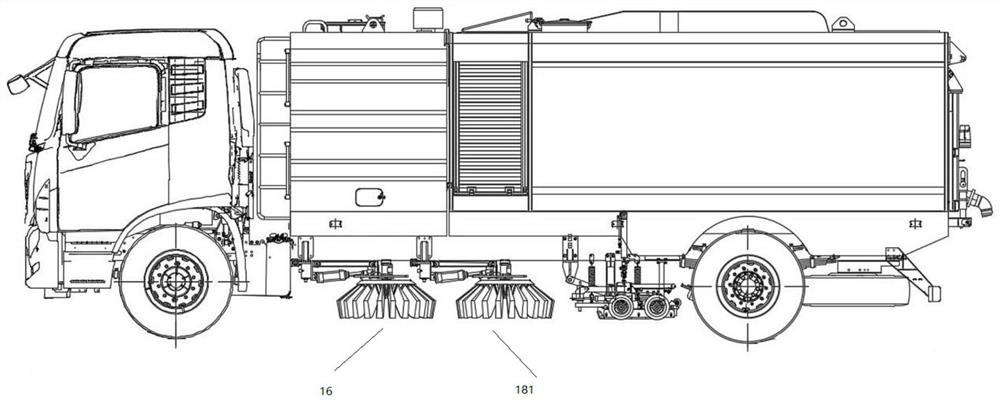

[0038] [Third embodiment] if figure 1 , 2 As shown, the panning motors include a left panning motor 16 and a right panning motor 181 .

[0039] In the above embodiment, there are preferably two sweeping motors, which are specifically arranged on the lower surface of the middle part of the car body. The left sweeping motor 16 controls a row of left sweeping brushes, and the right sweeping motor 181 controls a row of right sweeping brushes. disk, the rotation direction of the left pan motor 16 and the right pan motor 181 is fixed. Garbage can be swept into the box in the sweeper.

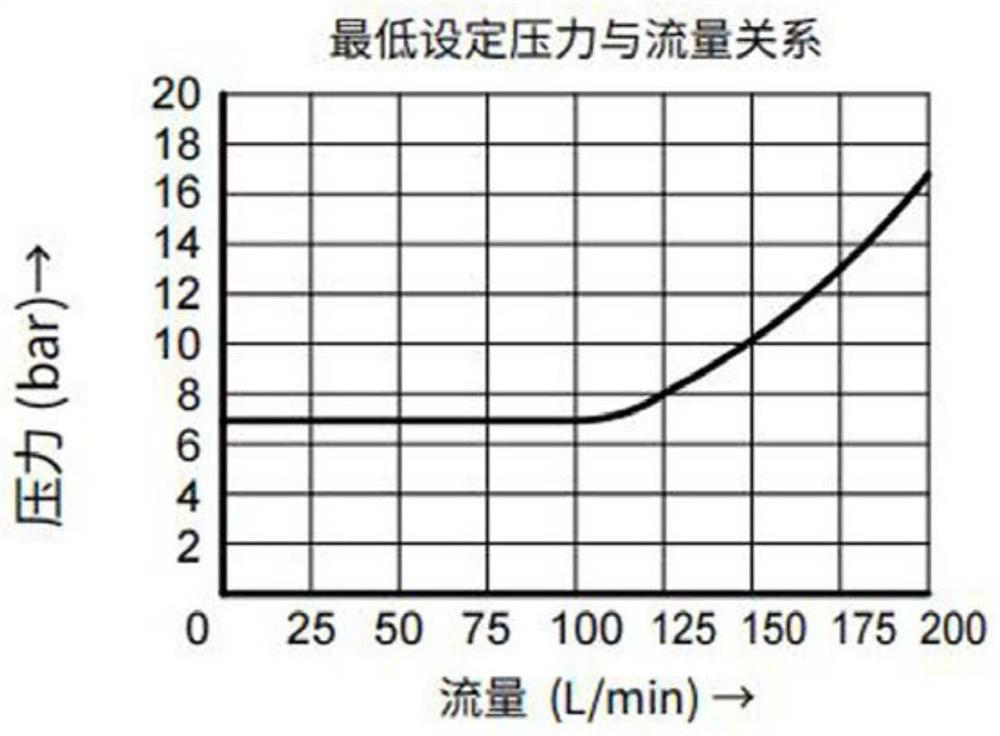

[0040] [Fourth Embodiment] If figure 1 , 3 , 4, the valve group 10 includes: a first one-way valve 12, the first one-way valve 12 is used to control the flow direction of hydraulic oil in the oil circuit; Set different set current values; proportional directional valve 14, proportional directional valve 14 sets different set voltage values under different working conditions; valve block, valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com