Preparation method of zirconium tungstate-containing aluminum-based composite material with high comprehensive performance

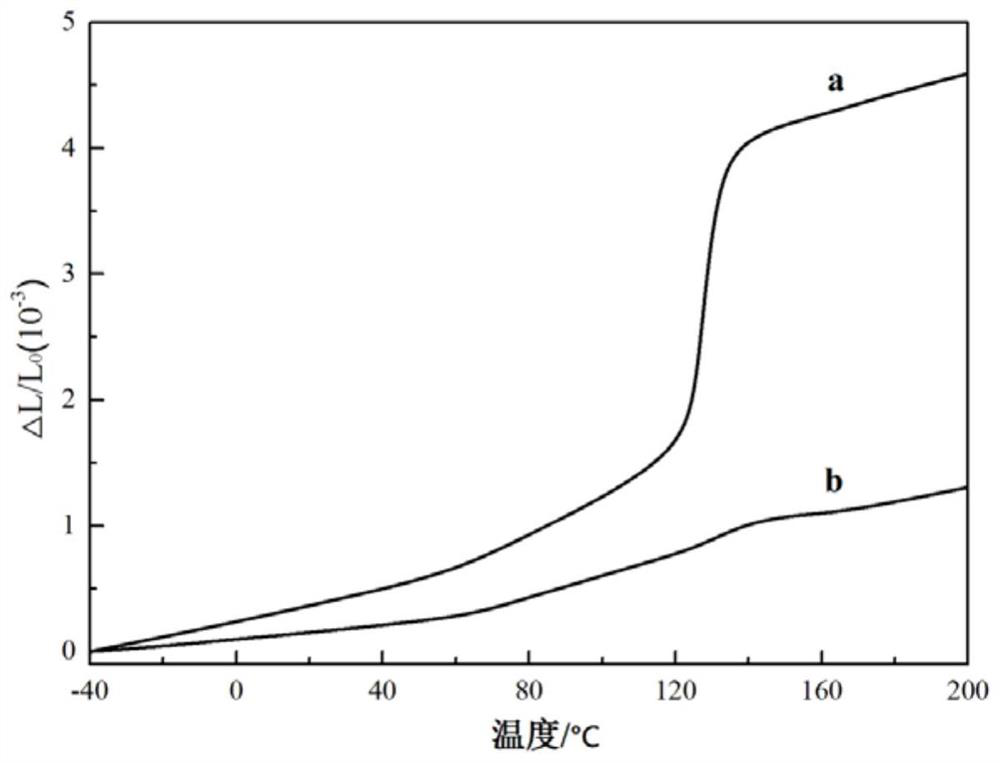

A technology of aluminum-based composite materials and comprehensive performance, which is applied in the field of preparation of aluminum-based composite materials, can solve the problems of large thermal expansion coefficient and low strength of composite materials, and achieve the goal of increasing strength, improving comprehensive performance, and facilitating industrial production and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] Specific implementation mode one: ZrW containing ZrW with high comprehensive performance in this implementation mode 2 o 8 The preparation method of the aluminum matrix composite material is carried out according to the following steps:

[0041] 1. Weighing:

[0042] Weigh ZrW 2 o 8 powder, high-strength ceramic powder and aluminum matrix as raw materials;

[0043] The volume fraction of the aluminum matrix in the raw material is 5-40%, the volume fraction of the high-strength ceramic powder is 0.1-15%, and the ZrW 2 o 8 Powder is the balance;

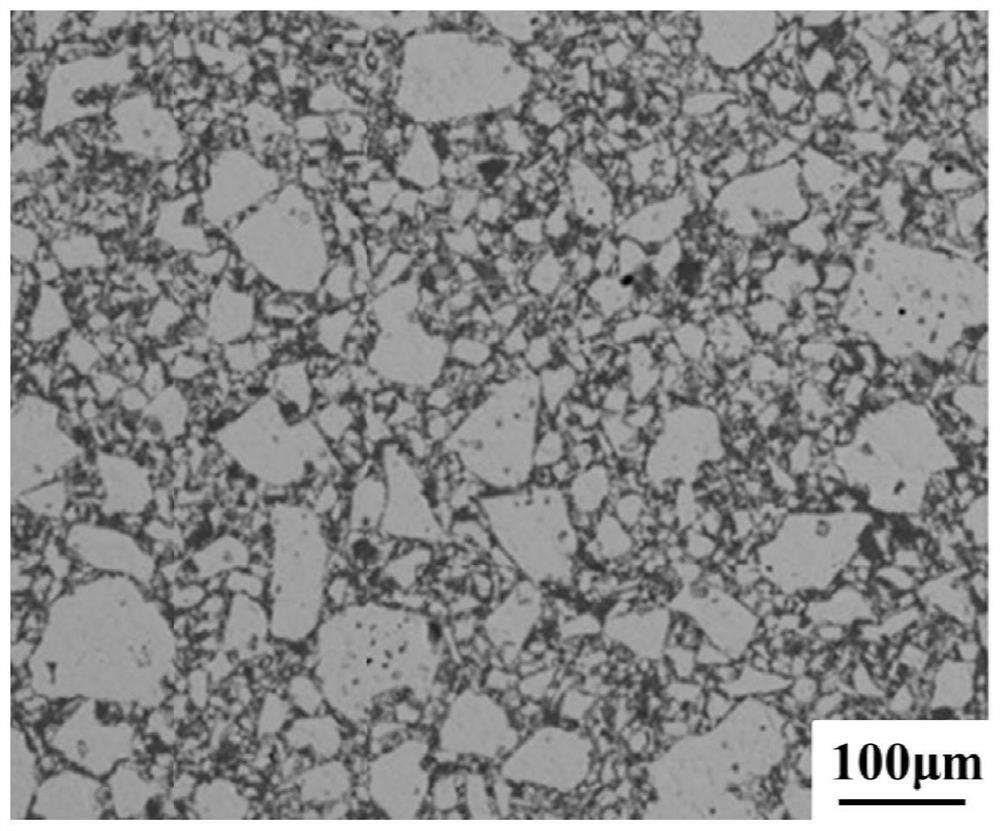

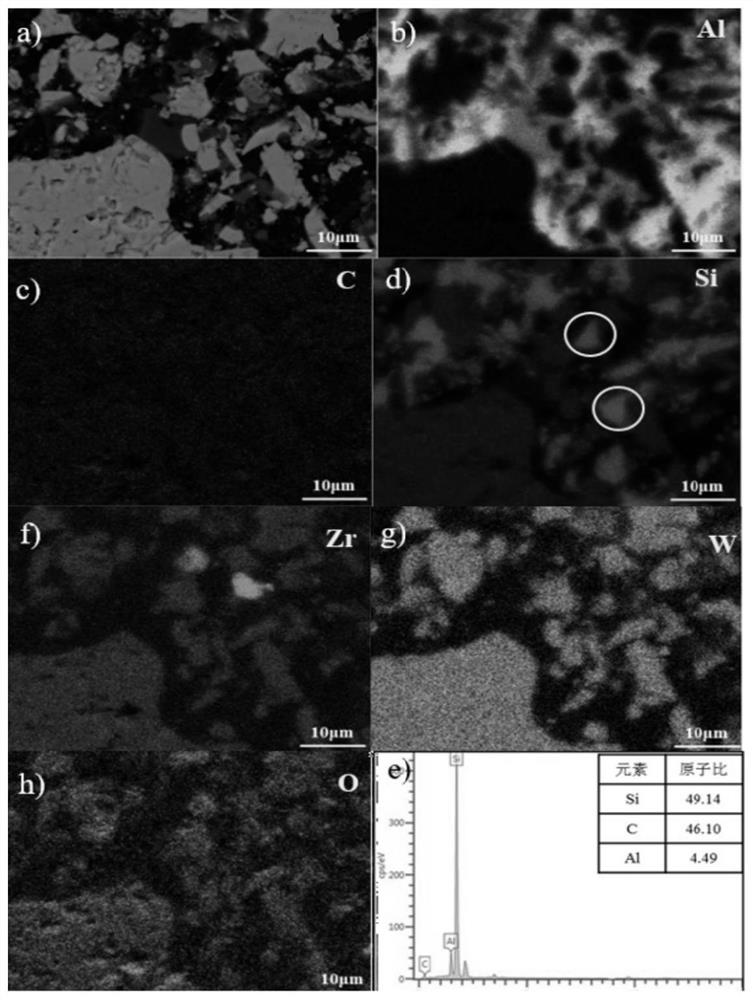

[0044] The average particle size of the high-strength ceramic powder is 0.5-15 μm; ZrW 2 o 8 The powder consists of 2-5 kinds of ZrW with different average particle sizes 2 o 8 Powder mixed, ZrW 2 o 8 The average particle size of powder is 0.5~200μm;

[0045] The high-strength ceramic powder is SiC powder, B 4 C powder, Al 2 o 3 One or a combination of several powders;

[0046] 2. Preparation of reinforcement pref...

specific Embodiment approach 2

[0064] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the aluminum substrate in step 1 is pure aluminum or aluminum alloy; the aluminum alloy is Al-Si alloy, Al-Si-Cu alloy, Al-Cu -Mg alloy, Al-Zn-Cu alloy, Al-Zn-Mg-Cu alloy, Al-Si-Cu-Mg alloy or a combination of several of them.

specific Embodiment approach 3

[0065] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ball milling process described in step two is: the ball-to-material ratio is (5-20):1, the rotating speed is 100-250rpm, and the time is 1-15h .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com