Composite ceramic material with phase-change temperature regulation function and preparation method and application thereof

A composite ceramic and organic phase technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of inability to play the role of phase change energy storage, thermal energy transmission, and energy storage materials unable to play the role of phase change energy storage. Good phase change energy storage function, the effect of isolating high temperature heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

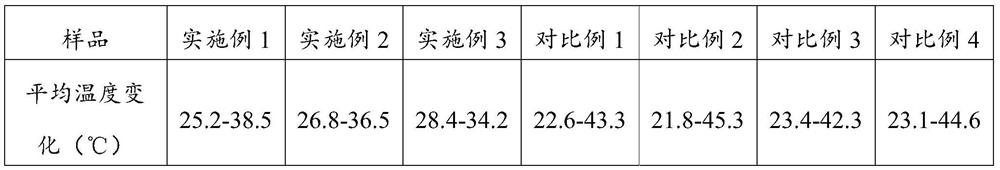

Examples

Embodiment 1

[0043] A composite ceramic material, the composite ceramic material has a double-wrapped core-shell structure, wherein: the core of the core-shell structure is paraffin, and the shell layer of the core-shell structure includes a zinc oxide thermal insulation layer and a titanium dioxide protective layer from the inside to the outside; The average particle size of the composite ceramic material is 200-400nm.

[0044] A method for preparing a composite ceramic material, comprising the steps of:

[0045] (1) Add 8 grams of paraffin to 50 grams of water and 2 grams of sodium lauryl sulfate, stir at a speed of 6000r / min and a temperature of 70°C for 10 minutes; then add 4 grams of zinc acetate dihydrate dropwise and continue stirring for 5 minutes Finally, add a sodium hydroxide solution with a mass fraction of 3% to adjust the pH of the solution to 8, continue to stir for 1 hour, age for 3 hours, centrifuge, wash and dry to obtain a single-layer wrapping material;

[0046] (2) Ad...

Embodiment 2

[0051] A composite ceramic material, the composite ceramic material has a double-wrapped core-shell structure, wherein: the core of the core-shell structure is paraffin, and the shell layer of the core-shell structure includes a zinc oxide thermal insulation layer and a titanium dioxide protective layer from the inside to the outside; The particle size of the composite ceramic material is 400-600nm.

[0052] A method for preparing a composite ceramic material, comprising the steps of:

[0053] (1) Add 12 grams of paraffin into 75 grams of water and 3 grams of sodium dodecylsulfonate, and stir for 15 minutes at a speed of 7500r / min and a temperature of 80°C; then add 6 grams of zinc acetate dihydrate dropwise and continue stirring After 8 minutes, add sodium hydroxide solution with a mass fraction of 4.5% to adjust the pH of the solution to 8, continue stirring for 1.5 hours, age for 5.5 hours, centrifuge, wash and dry to obtain a single-layer wrapping material;

[0054] (2) A...

Embodiment 3

[0059] A composite ceramic material, the composite ceramic material has a double-wrapped core-shell structure, wherein: the core of the core-shell structure is paraffin, and the shell layer of the core-shell structure includes a zinc oxide thermal insulation layer and a titanium dioxide protective layer from the inside to the outside; The particle size of the composite ceramic material is 600-900nm.

[0060] A method for preparing a composite ceramic material, comprising the steps of:

[0061] (1) Add 16 grams of paraffin to 80 grams of water and 4 grams of sodium lauryl phosphate, and stir at a speed of 8000r / min and a temperature of 80°C for 20 minutes; then add 8 grams of zinc acetate dihydrate dropwise and continue stirring for 10 minutes Finally, add a sodium hydroxide solution with a mass fraction of 5% to adjust the pH of the solution to 9, continue to stir for 2 hours, age for 8 hours, centrifugally wash and dry to obtain a single-layer wrapping material;

[0062] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com