High-toughness and high-fluidity PC (polycarbonate) composition as well as preparation method and application thereof

A technology of high fluidity and composition, applied in the field of engineering plastics, can solve the problems of poor transparency, processability and toughness, and achieve the effects of good toughness, improved compatibility and low visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

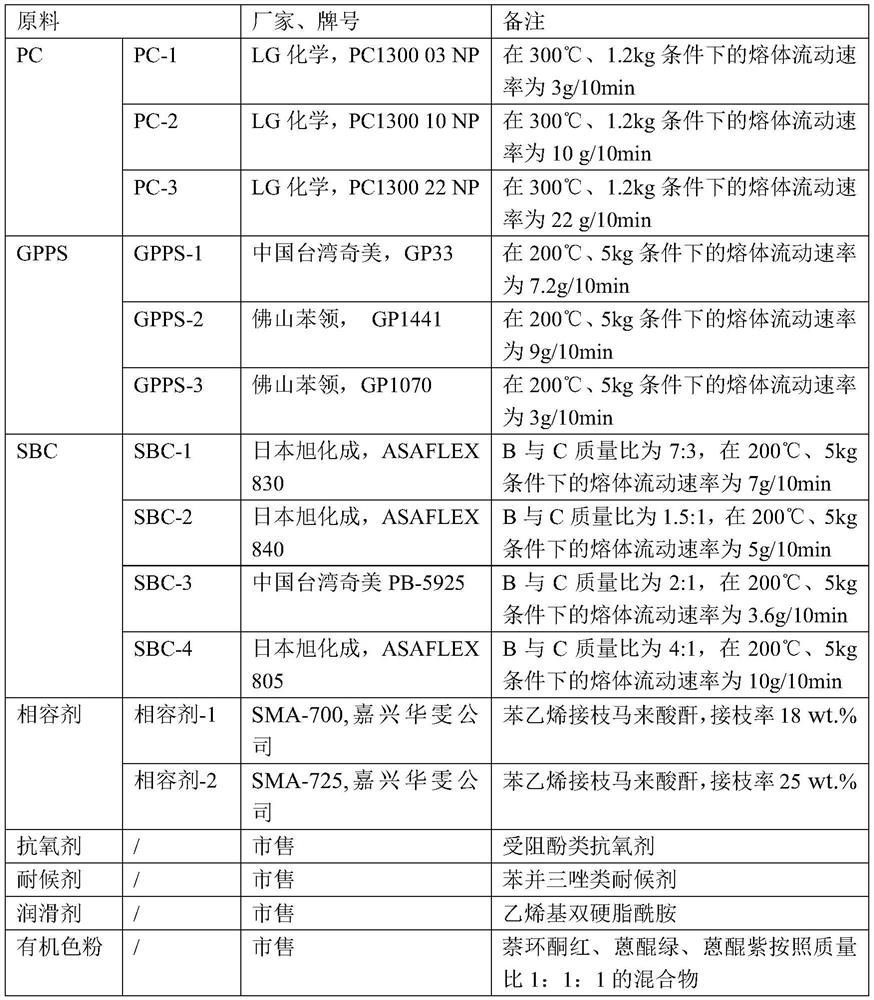

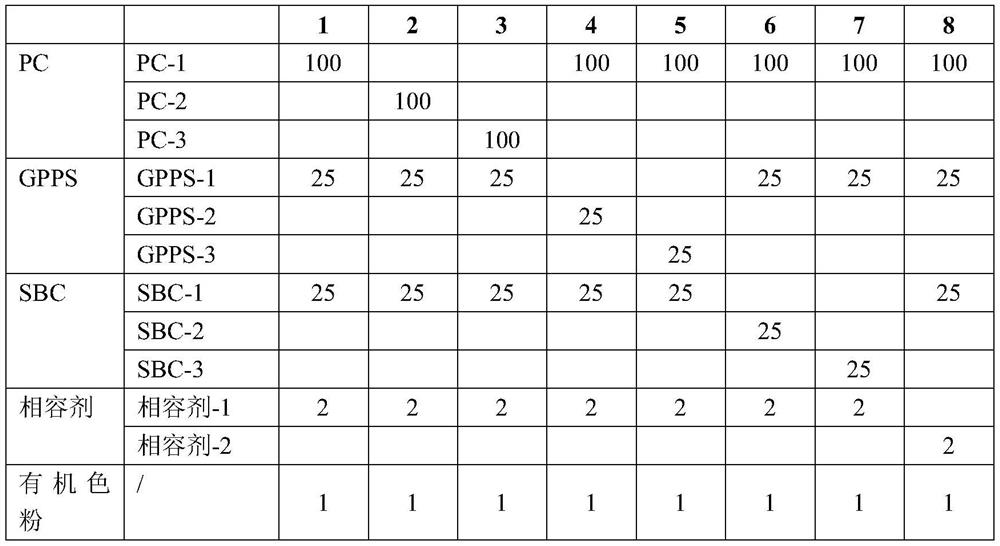

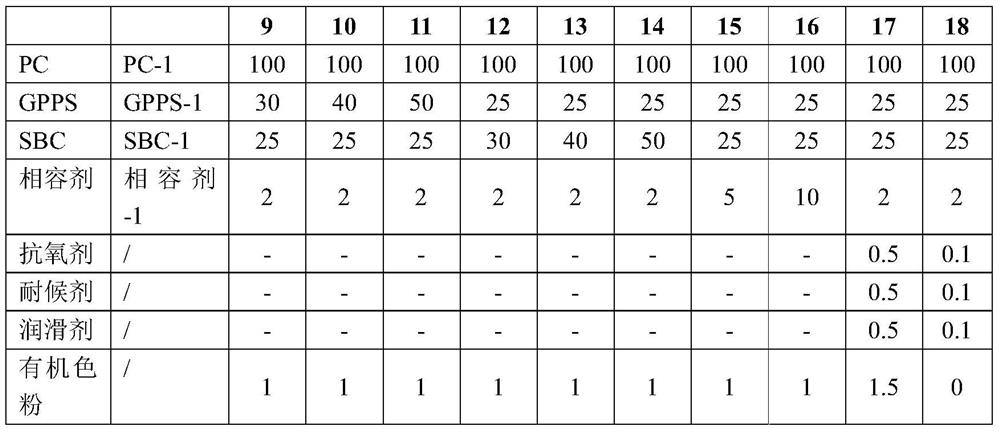

[0050] The component contents of the PC compositions of Examples 1-18 are shown in Table 1, and the preparation method is as follows:

[0051] After mixing the components according to Table 1, add them to the extruder, melt and mix, extrude and granulate to obtain the PC composition;

[0052] The extruder is a twin-screw extruder, the extrusion temperature is 220-300°C, the length-to-diameter ratio of the screw is 44:1, and the screw speed is 200-1000r / min.

[0053] Table 1 Component content (parts by weight) of the PC composition of Examples 1-18

[0054]

[0055]

Embodiment 18

[0073] Example 18 is a PC composition that does not contain organic toner. It can be seen that its visible light transmittance is 88%, and its transparency is good. It is suitable for use as a resin matrix for infrared-transmitting materials.

[0074] Table 4 Test results of comparative examples 1 to 6

[0075]

[0076] According to the test results in Table 4, in Comparative Example 1, without GPPS, the melt flow rate of the PC composition was only 8.1 g / 10 min, indicating that its fluidity was poor and processing difficulty was high. In Comparative Example 2, although a part of GPPS was added, the content of GPPS was too small, which limited the improvement of the processability of the PC composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com