Method for controlling proper mixing amount of polycarboxylic acid type admixture in premixed concrete

A technology of ready-mixed concrete and polycarboxylate, which is applied in the direction of mixing operation control, chemical instruments and methods, mixing operation control devices, etc., can solve the problems of inability to control product quality and service, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This example is an application example of how to determine the change in the amount of admixture after the mix ratio of C30 concrete is changed after the raw material is changed.

[0056] C30 concrete mix ratio and methylene blue value calculation:

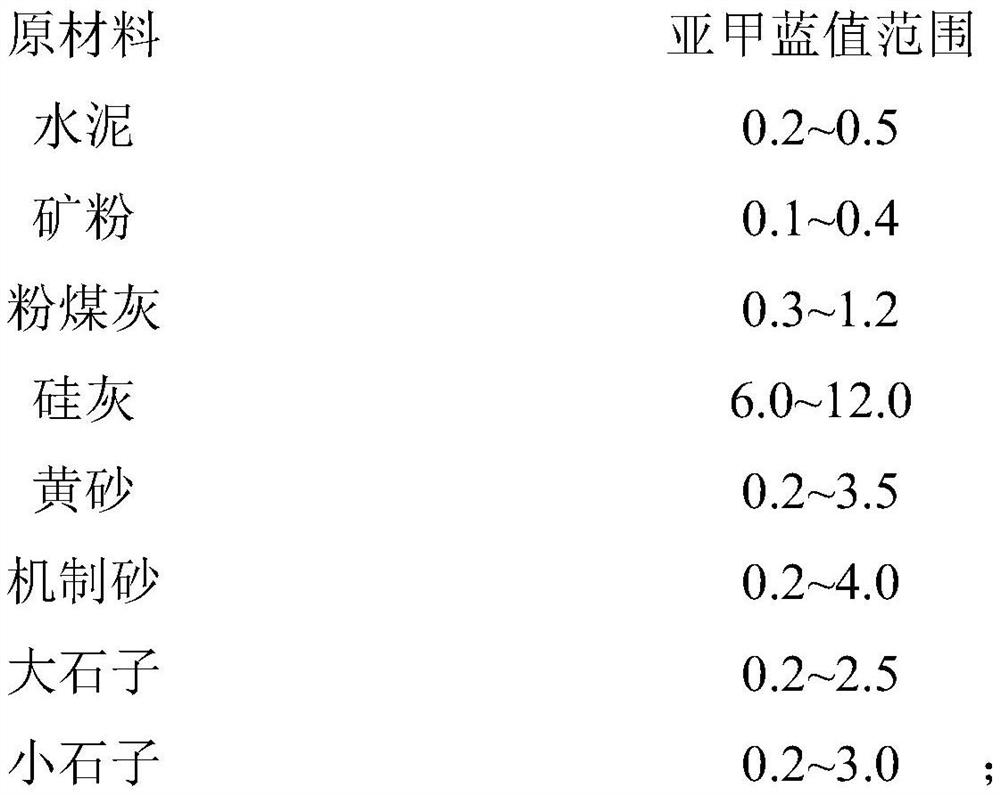

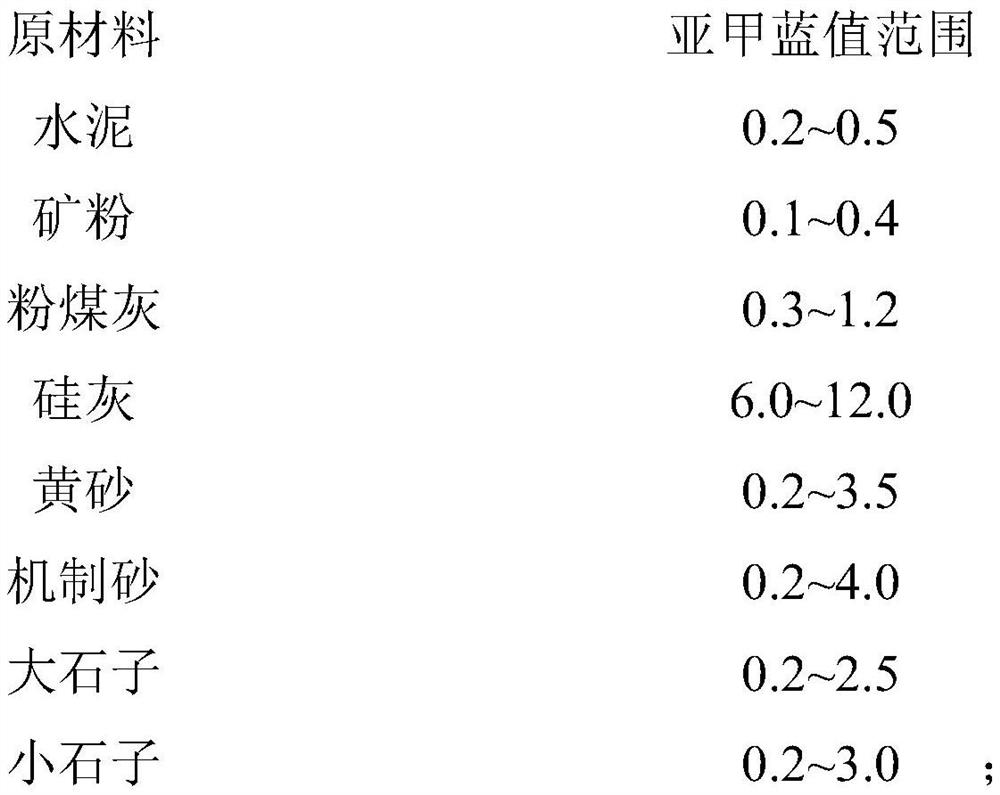

[0057] Table 3C30 concrete mix ratio and methylene blue value

[0058]

[0059] According to the calculation formula of the patent of the present invention, the calculation is as follows:

[0060] m 总 =∑(ΔMB i × m i ) / 1000=(0.1*312+0.5*465+0.1*300) / 1000=0.2937Kg

[0061] m 外固 = M 总 ×α=0.2937*0.2=0.05874Kg

[0062] The effective solid content of the polycarboxylate admixture used is 12%, and the amount of variation of the admixture can be obtained as:

[0063] W 外 = M 外含 / a=0.05874 / 0.12=0.4895Kg

[0064] Finally calculate the amount of admixture in the mixing ratio after the change of raw materials = 6.81 + 0.4895 = 7.3Kg

[0065] Through small trial mixing, the properties of C30 concrete at the initial stage ...

Embodiment 2

[0069] This embodiment is to illustrate the application of the patent of the present invention by taking a C50 concrete mix ratio as an example:

[0070] Table 4C50 concrete mix ratio and methylene blue value

[0071]

[0072] According to the calculation formula of the patent of the present invention, the calculation is as follows:

[0073] m 总 =∑(ΔMB i × m i ) / 1000=(0.1*1010-0.1*725) / 1000=0.282Kg

[0074] m 外固 = M 总 ×α=0.282*0.2=0.0564Kg

[0075] The effective solid content of the polycarboxylate additive used is 18%, can obtain:

[0076] W 外 = M 外含 / a=0.0564 / 0.18=0.3133

[0077] Finally, calculate the amount of admixture in the mixing ratio after the change of raw materials = 5.8 + 0.3133 = 6.113Kg, and through small trial mixing, the performance of the adjusted C50 concrete is as follows:

[0078] C50 Slump Expansion Ease of use 28-day compressive strength initial 225mm 520*520mm good 58.9Mpa Variety 220mm 510*520mm goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com