Ship accessory machining platform with air tightness detection mechanism

A technology for air tightness detection and processing platform, which can be applied in the direction of detecting the appearance of fluid at the leak point, working table, using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problem of low work efficiency and no air tightness setting. Detection device and other problems, to achieve the effect of convenient and fast transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

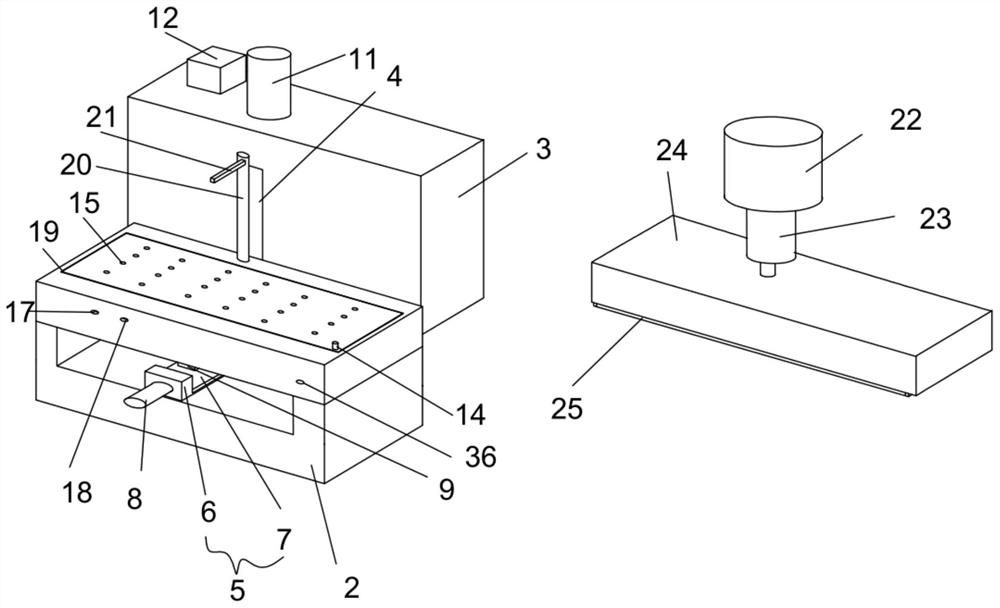

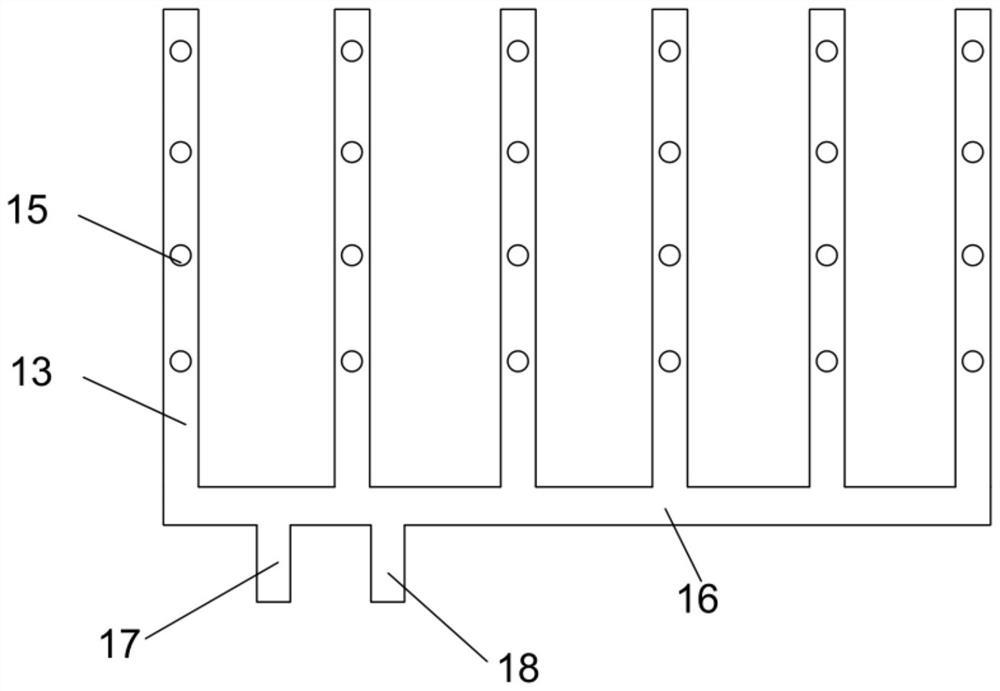

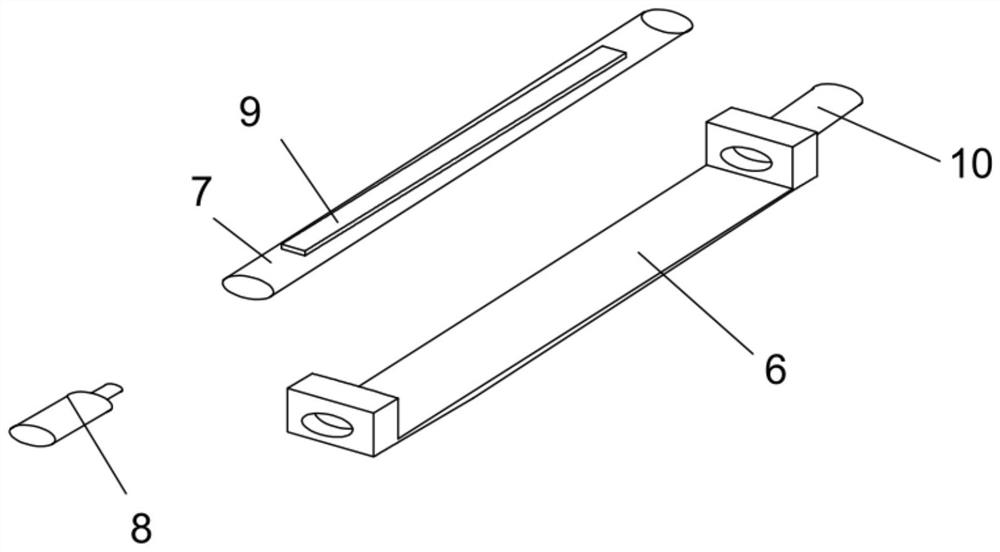

[0028] see Figure 1-Figure 3 , an embodiment provided by the present invention: a ship accessories processing platform with an air tightness detection mechanism, including a processing table 1, the processing table 1 is placed on the "凵"-shaped base 2, and also includes The stretch platform 3 is provided with a vertical chute 4 along the stretch platform 3, and a slide seat 5 is slidably connected in the chute 4. The slide seat 5 includes a "凵"-shaped support 6, and the "凵"-shaped support The slotted hole of the seat 6 is connected with a rotating shaft 7, and one side of the "凵"-shaped support 6 is provided with a first motor 8 that drives the rotating shaft 7 to rotate, and above the rotating shaft 7, the connecting seat 9 and the The bottom of the processing table 1 is connected, and the other side of the "凵"-shaped support 6 is provided with a slider 10, and the slider 10 is slidably connected with the slider 5, and is arranged above the extending platform 3. There is a ...

Embodiment 2

[0031] see Figure 4 , an embodiment provided by the present invention: a ship accessories processing platform with an air tightness detection mechanism, further, in order to realize quick adjustment, a third third Cylinder 26, the piston rod of the third cylinder 26 runs through the left or right side of the "凵"-shaped base 2 and is connected with a push plate 27, the bottom of the push plate 27 is offset against the bottom of the processing table 1, through With the above structure, when it is necessary to change the angle of the processing table 1, the third cylinder 26 on the other side is driven to work, and the processing table 1 is synchronously pushed to work, and finally ensure that the angle can be adjusted quickly to realize fast delivery of ship accessories.

[0032] Further, in order to improve the fixing effect, the bottom of the push plate 27 is provided with an electromagnet 28 that is powered and has magnetism, and the bottom of the processing table 1 is provi...

Embodiment 3

[0034] see Figure 5 , an embodiment provided by the present invention: a ship accessories processing platform with an airtightness detection mechanism. As a preference, in order to improve the efficiency of airtightness detection, a protruding processing platform 1 is connected to the sealing groove 19 The suction pipe 31 on the side wall, the other end of the suction pipe 31 is connected with a vacuum pump 30, and the inside can be vacuumed by setting the suction pipe 31 and the vacuum pump 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com