an oil-filled motor

An oil motor and barrel technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of complex procedures, affecting air cavity sealing, difficult to fix bolts, etc., and achieve the effect of simplifying procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

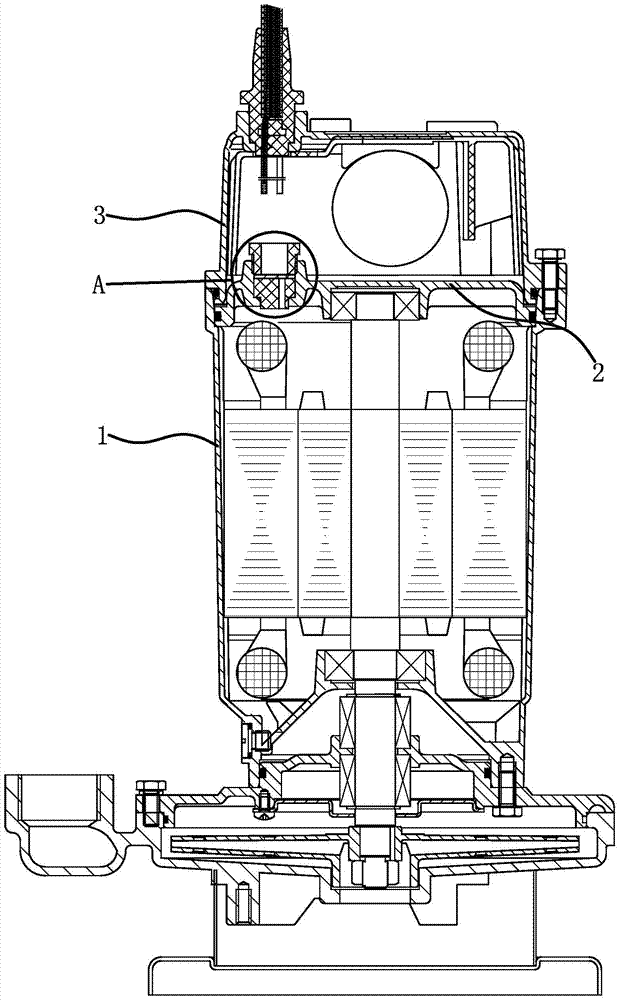

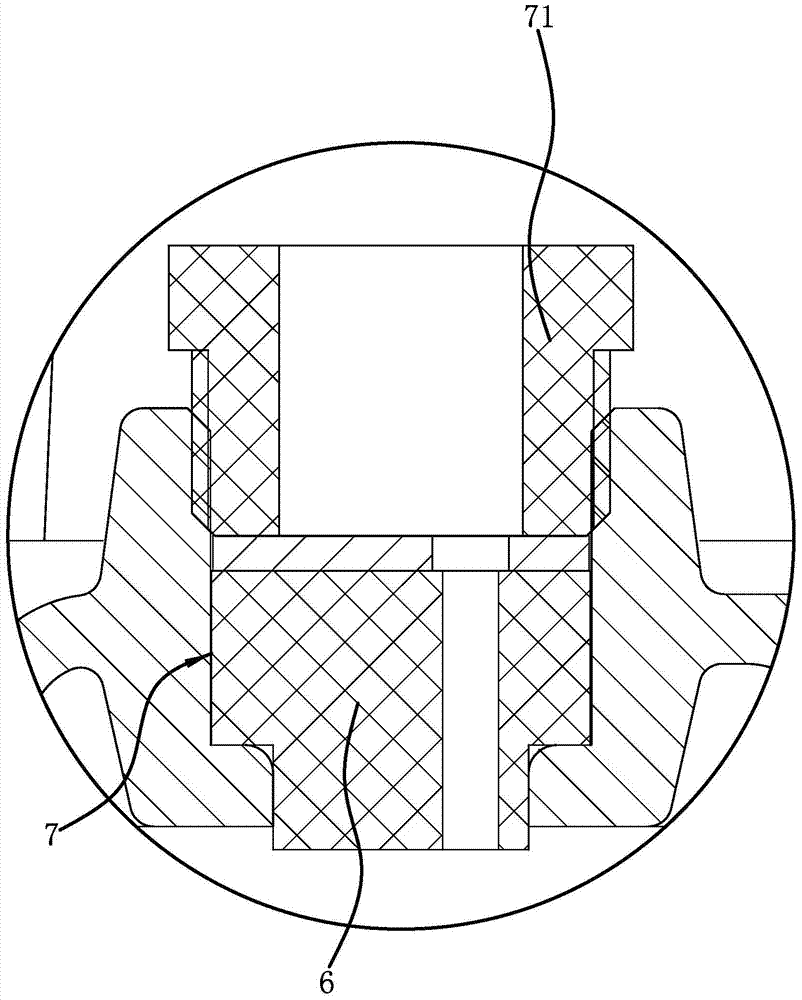

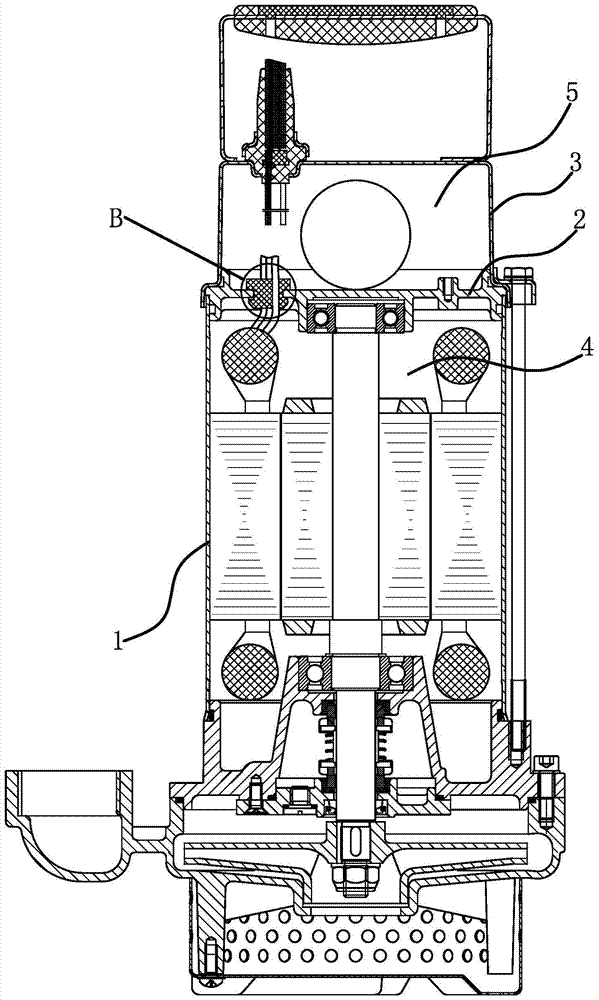

[0027] Such as image 3 , Figure 4As shown, an oil-filled motor includes a machine barrel 1, an upper bearing seat 2 and an upper cap 3, one end of the machine barrel 1 is closed, the upper bearing seat 2 is sealed and fixedly connected to the other end of the machine barrel 1, and the upper cap 3 is sealed and fixed. Connected to the upper bearing seat 2, an oil chamber 4 is formed between the upper bearing seat 2 and the barrel 1, which is used to install motor shafts, rotors, stators and other components. At the same time, a certain amount of lubricating oil needs to be filled in the oil chamber 4 for For cooling and lubrication, an air chamber 5 is formed between the upper bearing seat 2 and the upper cap 3, which is used to install electronic components, control panels and other components. The upper bearing seat 2 is provided with a detection hole 21 connecting the oil chamber 4 and the air chamber 5 A cylindrical and elastic outlet sheath 6 is fixedly inserted into th...

Embodiment 2

[0031] The structure of the oil-filled motor is basically the same as that of Embodiment 1, the difference is that Figure 6 As shown, the introduction structure includes an introduction tapered surface 622, the introduction tapered surface 622 is located at the end face edge of the limit portion 62 and the upper bearing seat 2, and the smaller end edge of the introduction tapered surface 622 is in contact with the side surface of the upper bearing seat 2 In contact with each other, the gas in the oil chamber 4 can squeeze the limit part 62 at the introduction tapered surface 622, so that a gap is formed between the end surface of the limit part 62 and the side surface of the upper bearing seat 2, and the gas enters the gap and further squeezes the radial direction. Extrude the outlet sheath 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com