External expansion type sealing detection device

A sealing detection and external expansion technology, which can be used in liquid/vacuum measurement for liquid tightness and by measuring the acceleration and deceleration rate of fluid, etc. It can solve problems such as difficulty in guaranteeing product quality, poor accuracy, and large leakage risk. To achieve the effect of convenient operation, guaranteeing effectiveness and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

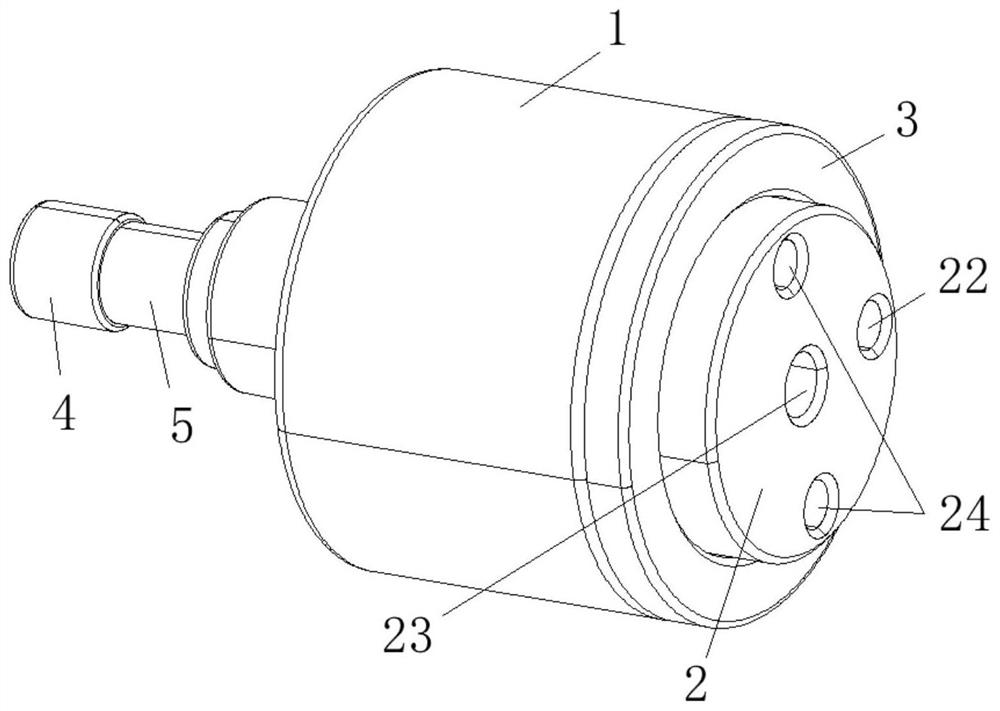

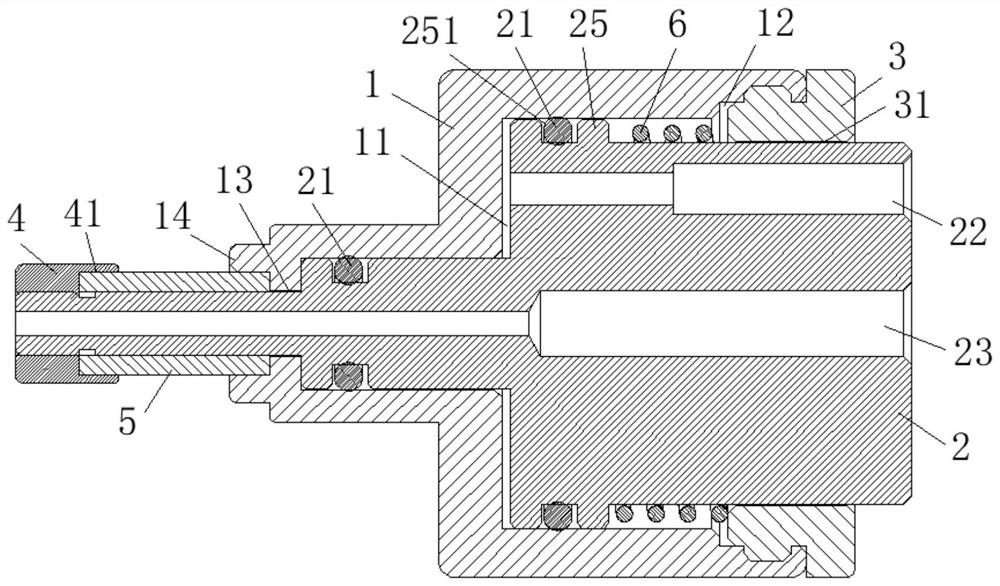

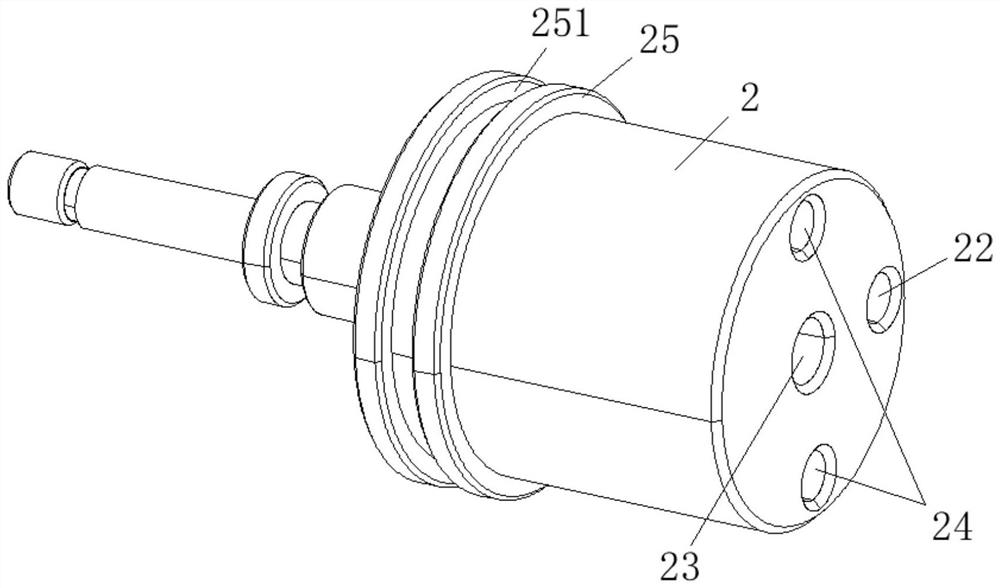

[0027] In order to make it easy to understand the technical means, creative features, goals and effects realized by the present invention, the following embodiments are combined with the appendix. figure 1 to the attached image 3 The technical solutions provided by the present invention are described in detail, but the following contents are not intended to limit the present invention.

[0028] figure 1 It is a structural diagram of an embodiment of an outwardly expanding seal detection device of the present invention; figure 2 It is a cross-sectional view of a preferred embodiment of the present invention. like figure 1 and figure 2 As shown, the external expansion seal detection device provided in this embodiment includes: an outer casing 1 , an inner core 2 , a tail cover 3 , a pressure head 4 and an elastic expansion ring 5 .

[0029] Specifically, the cross-section of the outer casing 1 is circular, and the outer casing 1 has a sliding cavity 11 with an opening 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com