Turning anti-deformation bidirectional structure and method based on edge long overhanging thin wall

An anti-deformation and overhang technology, used in turning equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of no positioning surface support, uncontrollable turning deformation, and no axial bidirectional movement, achieving light weight, Optimized clamping layout, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

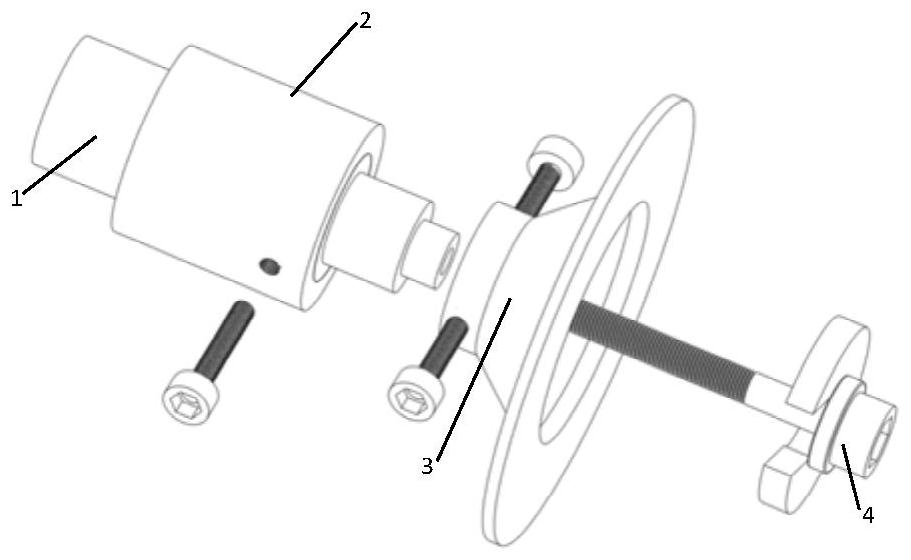

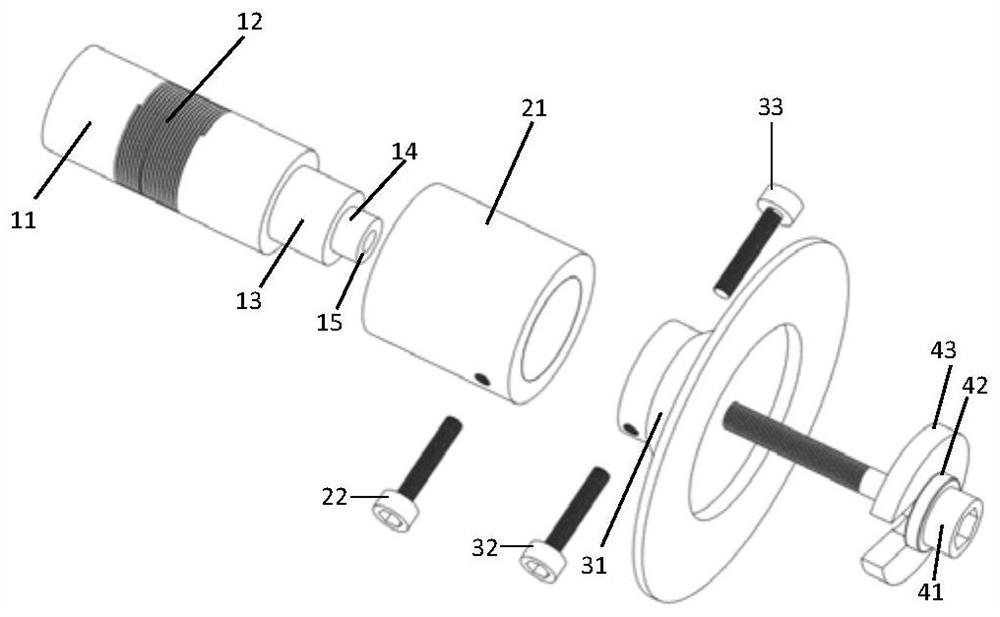

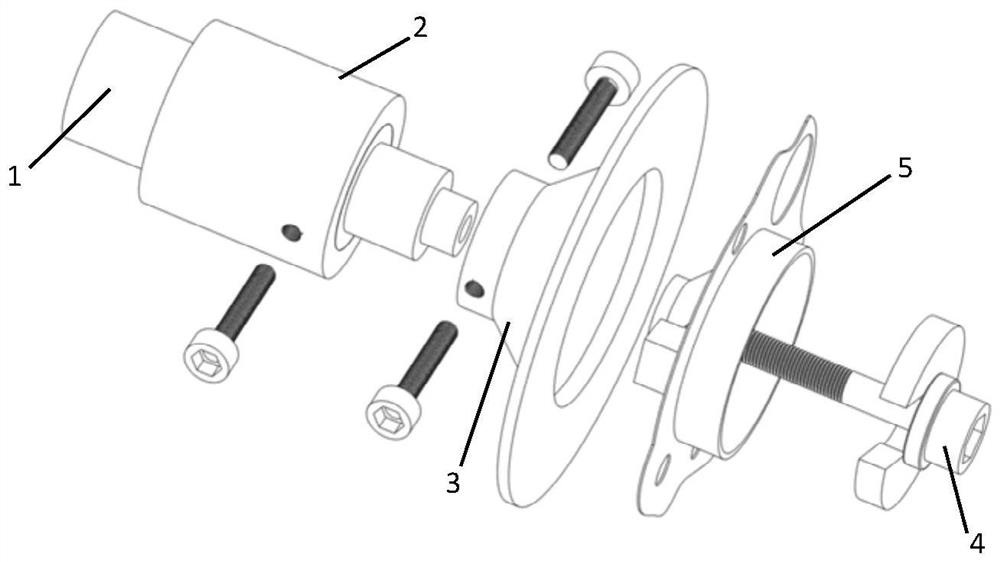

[0036] Embodiment: A preferred embodiment of the present invention is provided below. The structure of thin-walled parts with long overhangs on the edge: the center part of the gyratory has a sleeve-like end face and an end face with thin and elongated edges, showing a cantilevered state.

[0037] First, open the three-jaw chuck of the main shaft of the turning lathe, expand the size slightly larger than the size of the chuck shaft 11 of the base 1, and stuff it into the chuck shaft 11, so that the three-jaw chuck can not lose it, and then use Use a dial gauge to calibrate the workpiece positioning shaft 14 of the base 1 to no more than 0.01 and tighten the three claws; put on the thrust bushing 21 to expose the entire sliding shaft 13 and screw on the A locking screw 22; install the secondary positioning disc 3 on the sliding shaft 13, Install the B locking screw 32 and the C locking screw 33 on both sides at the same time; the clamping 4 is threadedly connected to the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com