Chitosan-tungsten disulfide aerogel composite material as well as preparation method and application thereof

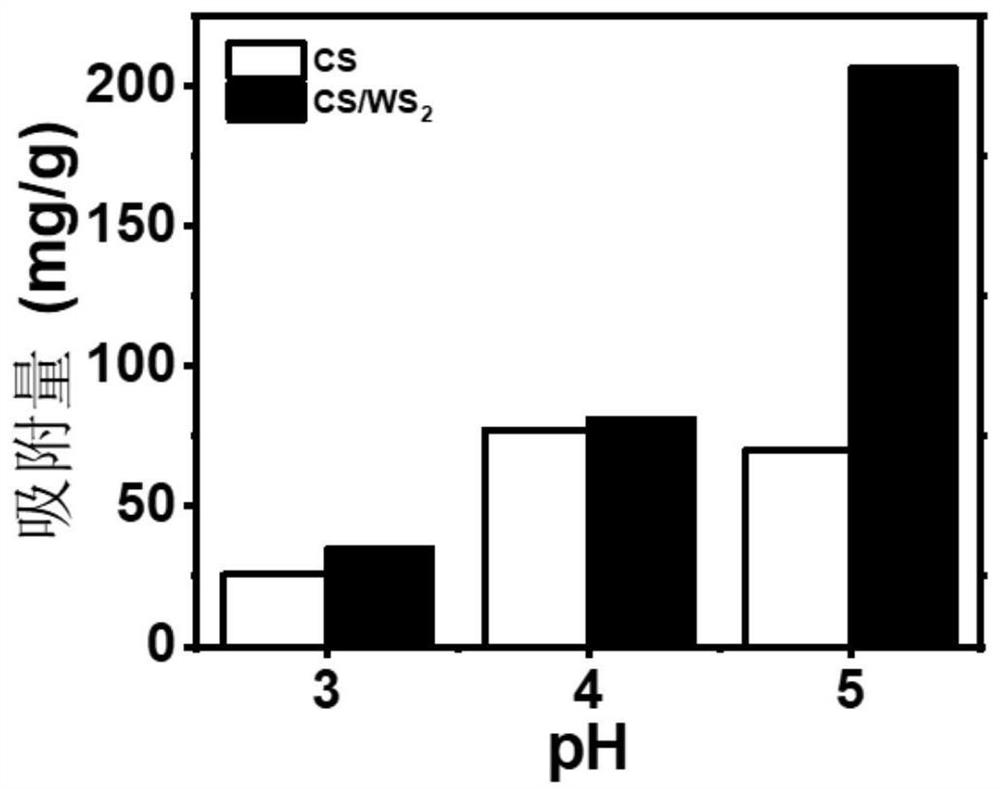

A technology of tungsten disulfide and composite materials, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of limited adsorption capacity, limited application, poor mechanical strength, etc., and achieve poor stability and good adsorption effect , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

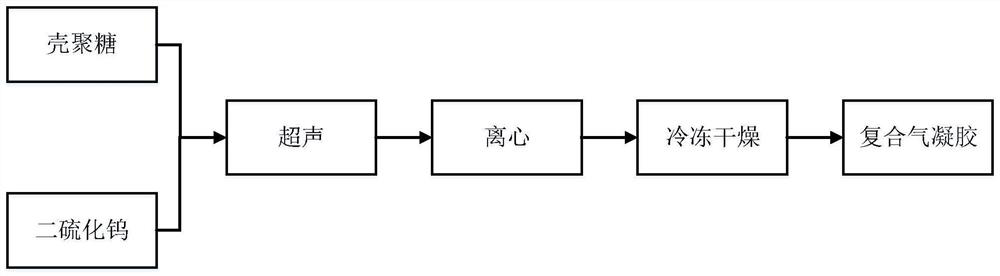

Method used

Image

Examples

Embodiment 1

[0046] The chitosan-tungsten disulfide airgel composite material described in present embodiment 1, described acid solution is glacial acetic acid, and the mass concentration of acid solution is 5%, and the solid-to-liquid ratio of chitosan and acid solution is 2 : 100, the unit is g / ml.

[0047] in:

[0048] The degree of deacetylation of chitosan is 80-95%.

[0049] The purity of said tungsten disulfide is 99.9%.

[0050] The preparation method of the chitosan-tungsten disulfide airgel composite material described in the present embodiment 1 is made up of the following steps:

[0051] (1) The amount of glacial acetic acid solution is 5ml, the amount of deionized water is 95ml, and chitosan is weighed 2g. After stirring for 8 hours and dissolving, let it stand for 24 hours to make it fully mixed, and prepare chitosan acid solution; wherein: chitosan and acid The solid-to-liquid ratio of the solution is 2:100, and the unit is g / ml.

[0052] (2) Put 0.5g tungsten disulfide ...

Embodiment 2

[0058]For the chitosan-tungsten disulfide airgel composite material described in Example 2, the acid solution is hydrochloric acid, and the mass concentration of the acid solution is 10%.

[0059] in:

[0060] The degree of deacetylation of chitosan is 80-95%.

[0061] The purity of said tungsten disulfide is 99.9%.

[0062] The preparation method of the chitosan-tungsten disulfide airgel composite material described in present embodiment 2 is made up of the following steps:

[0063] (1) The amount of hydrochloric acid solution is 10ml, the amount of deionized water is 90ml, and chitosan is weighed 1.5g. After stirring for 8h to dissolve completely, let it stand for 24h to prepare chitosan acid solution; wherein: the solid solution of chitosan and acid solution The liquid ratio is 1.5:100, and the unit is g / ml.

[0064] (2) Put 0.5g of tungsten disulfide into the stirred chitosan acid solution, put the mixed solution into an ultrasonic cleaner for ultrasonication for 6 hour...

Embodiment 3

[0070] For the chitosan-tungsten disulfide airgel composite material described in Example 3, the acid solution is formic acid, and the mass concentration of the acid solution is 5%.

[0071] in:

[0072] The degree of deacetylation of chitosan is 80-95%.

[0073] The purity of said tungsten disulfide is 99.9%.

[0074] The preparation method of the chitosan-tungsten disulfide airgel composite material described in the present embodiment 3 is made up of the following steps:

[0075] (1) 5ml of formic acid solution, 95ml of deionized water, 1g of chitosan, stirred for 8h to dissolve, left to stand for 24h to make it fully mixed, and prepared chitosan acid solution; wherein: chitosan and acid solution The solid-to-liquid ratio is 1:100, and the unit is g / ml.

[0076] (2) Put 0.5g of tungsten disulfide into the stirred chitosan acid solution, put the mixed solution into an ultrasonic cleaning machine for ultrasonication for 4 hours, the ultrasonic frequency is 40KHz, and the ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com