Preparation method of low-fat composite probiotic fermented emulsified sausage

A technology of compound probiotics and emulsified sausage, which is applied in food ingredients as emulsifiers, functions of food ingredients, food ultrasonic treatment, etc. It can solve the problems of inconsistent emulsification effect of emulsified intestines, harsh storage conditions of probiotics, short shelf life of probiotic products, etc. problem, to achieve the effect of enriching the flavor of emulsified sausage, making up for the lack of flavor substances, improving stability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Specifically, a method for preparing low-fat compound probiotic fermented emulsified sausage, which comprises the following steps:

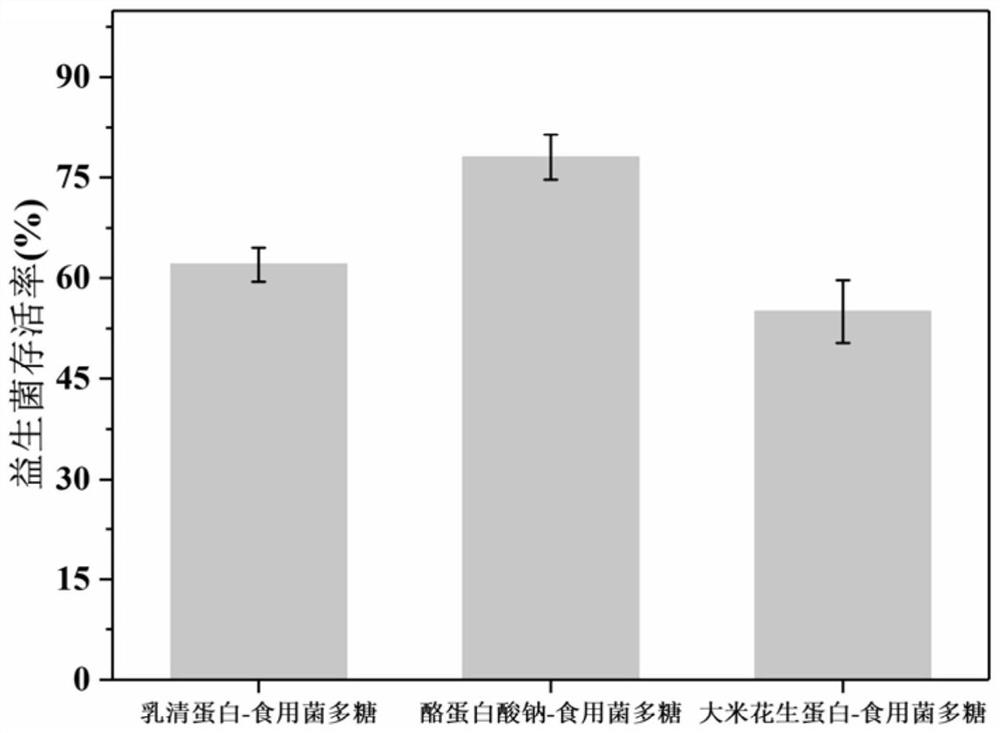

[0037] S1 Add the conjugate of sodium caseinate and edible fungus polysaccharide to the probiotic powder, add rapeseed oil and homogenize to obtain the probiotic encapsulated product;

[0038] S2 Adding the encapsulated probiotics to the mixture containing chicken after chopping to make stuffing and fermenting at 25-32°C for 6-10 hours;

[0039] S3 filling the fermented product in step S2 with a casing, pickling, and sterilizing to obtain emulsified sausage.

[0040] Among them, the main chain of edible fungus polysaccharides (including dextran, heterogalactan and heteroglucan in a mass ratio of 1 to 3:1 to 3:1 to 3) is composed of β-D(1-73 ) connected glucose groups, along the main chain randomly distributed with β-D (1-73) edge-connected glucose groups in a comb-like structure.

[0041] Sodium caseinate, the sodium salt of the main pro...

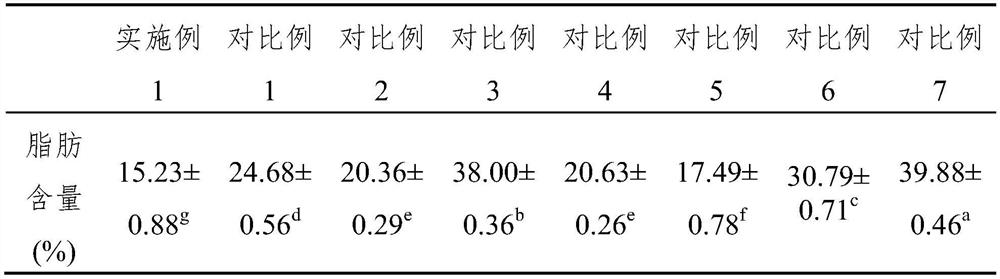

Embodiment 1

[0051] The preparation of low-fat compound probiotic fermented emulsified sausage is as follows:

[0052] Preparation of S1 Sodium Caseinate / Edible Fungus Polysaccharide Conjugate

[0053] Sodium caseinate and edible fungus polysaccharide (a mixture of dextran, heterogalactan and heteroglucan in a mass ratio of 1:1:2) were mixed at a pH of 7 in a mass ratio of 1:0.7 Mixing and coupling by Maillard reaction; specifically, the mixture of sodium caseinate and edible fungus polysaccharide is spray-dried at an inlet temperature of 130°C and an outlet temperature of 71°C, and the resulting powder is dried at a relative humidity of 65%, temperature Place it at 60°C for 5 days to obtain a sodium caseinate / edible fungus polysaccharide conjugate;

[0054] S2 Encapsulated Probiotics

[0055] Lactobacillus and bifidobacteria are added to 35% of the mass of the mixed probiotic fermentation broth (20% w / w) with an effective bacterial count ratio of 1:1 and an effective bacterial count of ...

Embodiment 2

[0064] The preparation of low-fat compound probiotic fermented emulsified sausage is as follows:

[0065] Preparation of S1 Sodium Caseinate / Edible Fungus Polysaccharide Conjugate

[0066] Sodium caseinate and edible fungus polysaccharide (a mixture of dextran, heterogalactan and heteroglucan in a mass ratio of 3:2:1) were mixed at a pH of 7 at a mass ratio of 1:0.6 Mixing and coupling by Maillard reaction: spray drying at an inlet temperature of 130°C and an outlet temperature of 71°C, and place the resulting powder at a relative humidity of 65% and a temperature of 60°C for 6 days to obtain sodium caseinate / Edible fungus polysaccharide conjugates;

[0067] S2 Encapsulated Probiotics

[0068] Lactobacillus and bifidobacteria are added into the mixed probiotic fermentation liquid (20% w / w) with 20% inulin according to the effective bacterial species ratio of 1:1, and then freeze-dried, and the probiotic powder is dissolved in the vegetable In seed oil (20% w / w), add 3% (w / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com